Automatic thread compound spraying device

A fuel injector and screw thread technology, which is applied in the field of automatic threaded fuel injectors, can solve the problems of high labor cost, lack of fully automatic thread oiling device, and waste of human resources, so as to improve utilization rate and save labor Cost, the effect of improving fuel injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with specific embodiments, where the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

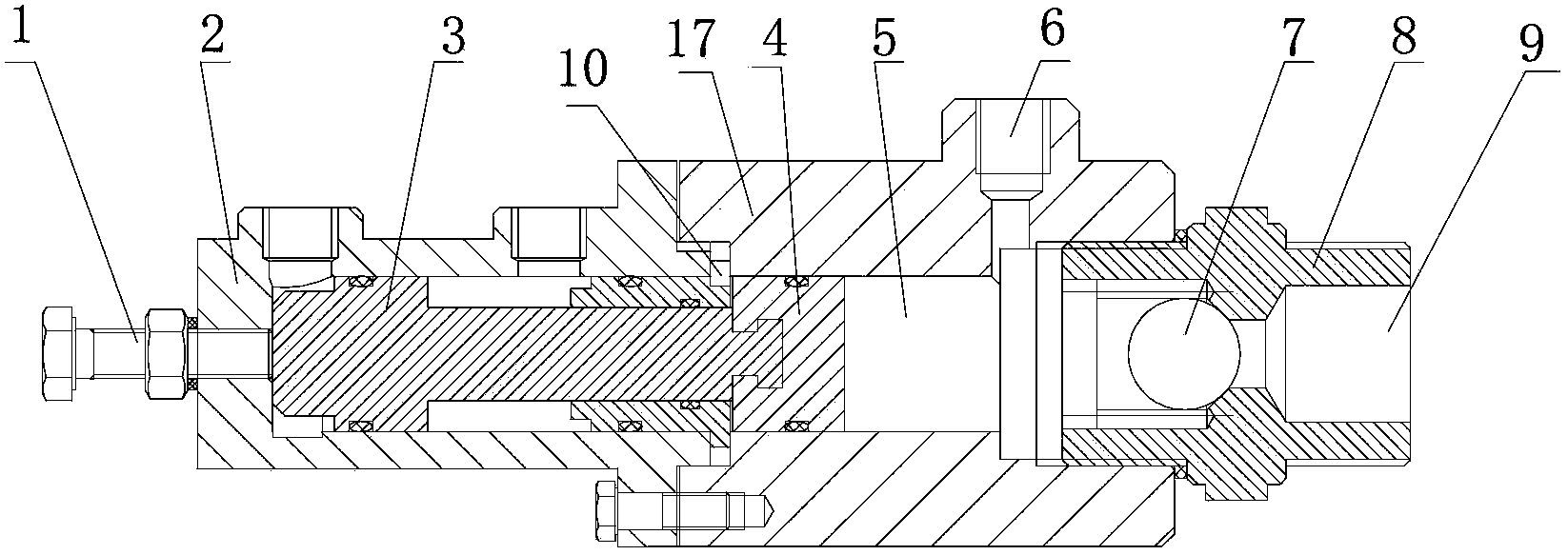

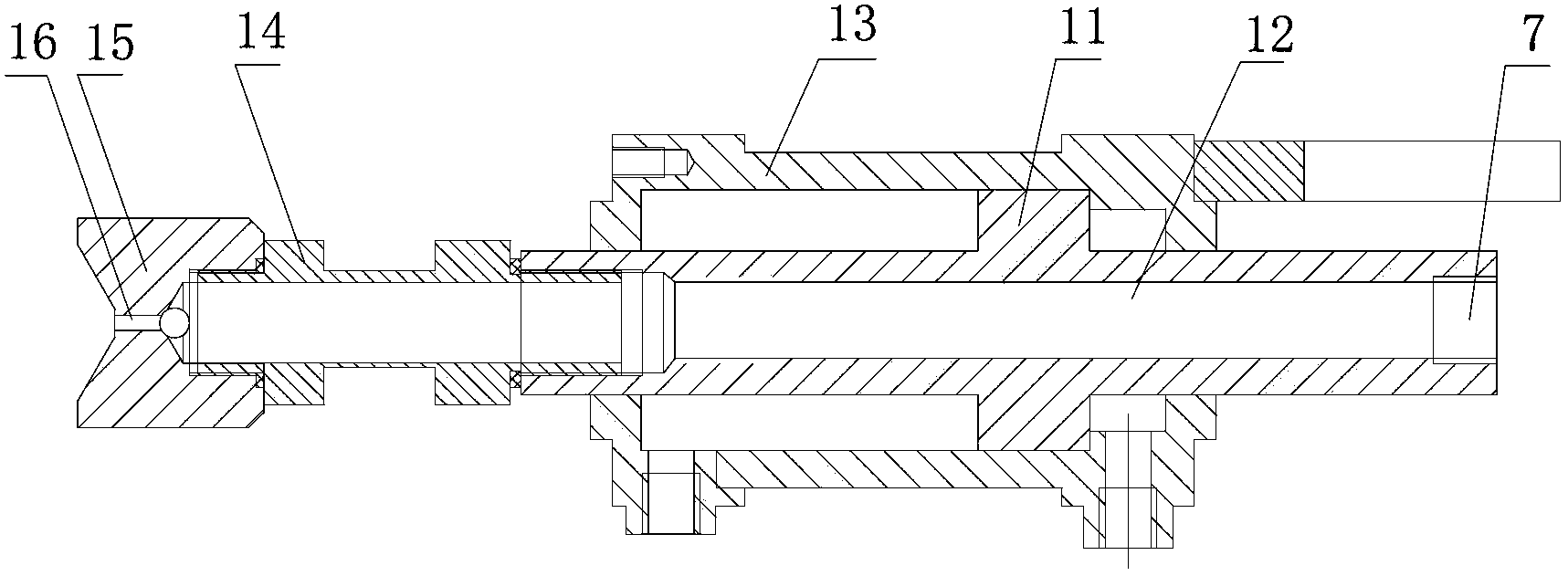

[0016] The automatic threaded fuel injector of the present invention, as attached figure 1 , 2 As shown, including the first cylinder 2 and the first

[0017] Two cylinders 17, the first cylinder 2 has a first piston rod 3, the second cylinder 17 has a threaded cavity 5, and the threaded cavity 5 is provided with the first piston rod. 3 matched piston 4, the other end of the first piston rod 3 is connected to the adjusting rod 1, the end of the threaded cavity 5 has a steel ball 7, and the end of the second cylinder 2 is connected to a one-way valve 8, the one-way The inner cavity of the valve 8 is the threaded oil inlet 9, the one-way valve 8 is connected to the threaded oil tank, and the connection between the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com