Method for performing three-proofing treatment on circuit board by using ultrasonic waves

A circuit board and ultrasonic technology, which is applied in the field of three-proof treatment of circuit boards, can solve the problems of missing coating, multi-coating, uneven coating, etc., and achieve the effect of no accumulation, high spraying efficiency and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

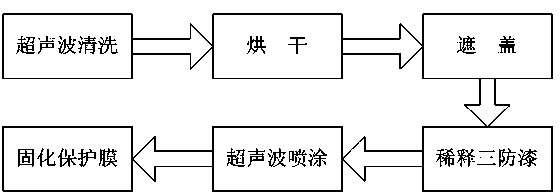

[0022] A technology for three-proof treatment of circuit boards using ultrasonic waves, characterized in that it includes the following steps:

[0023] Step (1) Set up the circuit boards in the cleaning tank in an orderly manner, inject a special cleaning agent for circuit boards or an environmentally friendly electronic ultrasonic cleaning agent into the cleaning tank, and completely soak the circuit boards in the tank; turn on the ultrasonic generator to generate high-pressure air bubbles, After ultrasonic cleaning for 20-30 minutes, disconnect the ultrasonic generator and take out the circuit board. Stand neatly on a stand and drain the cleaning agent.

[0024] Step (2) Put the cleaned and filtered circuit boards into the oven, and the loading quantity shall be half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com