Double-knot organic solar cell

A solar cell and organic technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low crystallinity of the photoactive layer film, failure to form effective current, poor stability, etc., to improve photoelectric conversion efficiency and enhance utilization efficiency , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Processing of transparent G / ITO:

[0035] After etching the electrode pattern on ITO conductive glass (Zhuhai Kaiwei Electronic Components Co., Ltd., square resistance 14Ω / □, transmittance 85%), it was first cleaned with detergent, and then deionized water, absolute ethanol, acetone and isotropic Ultrasonic cleaning with propanol for 10 minutes, drying with nitrogen gas, and UV / ozone treatment for 20 minutes.

[0036] Preparation of electron transport layer:

[0037] Spin-coat ZnO film on the surface of ITO, spin-coat at 3000rpm for 30s, and anneal at 150°C for 10min.

[0038] Preparation of the photoactive layer of the bottom cell:

[0039] Weigh 12mg P3HT and 12mg PC respectively 60 BM was dissolved in 1 mL of chlorobenzene, then 1 mg of ZnTPP was added, ultrasonically treated for 0.5 h, magnetically stirred at 70°C for 4 h, and then the mixture was spin-coated on the surface of the electron transport layer with a homogenizer to form a film. The speed of the homog...

Embodiment 2

[0052] Preparation of the photoactive layer of the bottom cell:

[0053] Weigh 12mg P3HT and 12mg PC respectively 60 BM was dissolved in 1 mL of chlorobenzene, then 0.2 mg of ZnTPP was added, ultrasonicated for 0.5 h, magnetically stirred at 70°C for 4 h, and then the mixed solution was spin-coated on a homogenizer. The speed of the homogenizer is 1000rpm, spin coating for 40s, and annealed at 130°C for 10min.

[0054] Preparation of the photoactive layer of the top cell:

[0055] Weigh 10mg PBDTTT-C-T and 15mg PC respectively 70 BM was dissolved in 1mL of chlorobenzene, 2mg of SiPc solution, sonicated for 0.5h, magnetically stirred at 70°C for 4h, and then the mixed solution was spin-coated on a homogenizer. The speed of the homogenizer is 1000rpm, and the spin coating is 40s.

[0056] Other preparation methods are the same as in Example 1.

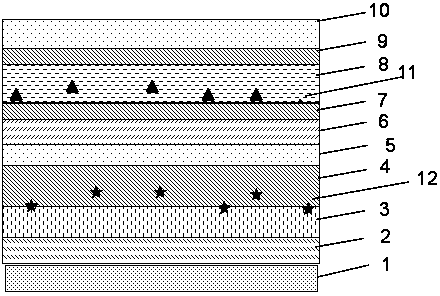

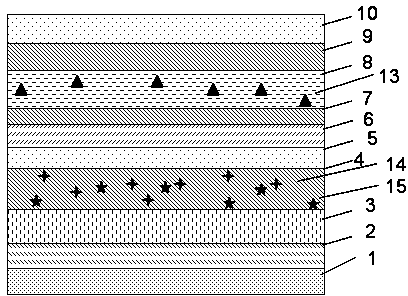

[0057] The device structure of the organic solar cell prepared by the above method is as follows figure 1 Shown: G / ITO / ZnO / P3HT:...

Embodiment 3

[0059] Preparation of the photoactive layer of the bottom cell:

[0060] Weigh 12mg P3HT and 12mg PC respectively 60 BM was dissolved in 1 mL chlorobenzene, then 0.1 mg Ir(ppy) was added 3 The solution was sonicated for 0.5 h, magnetically stirred at 70° C. for 4 h, and then the mixed solution was spin-coated on a homogenizer. The speed of the homogenizer is 1000rpm, spin coating for 40s, and annealed at 130°C for 10min.

[0061] Preparation of the photoactive layer of the top cell:

[0062] Weigh 10mg PBDTTT-C-T and 15mgPC respectively 70 BM was dissolved in 1mL of chlorobenzene, then a solution of 0.5mg of SiPc was added, ultrasonicated for 0.5h, magnetically stirred at 70°C for 4h, and then the mixed solution was spin-coated on a homogenizer. The speed of the homogenizer is 1000rpm, and the spin coating is 40s.

[0063] Other preparation methods are the same as in Example 1.

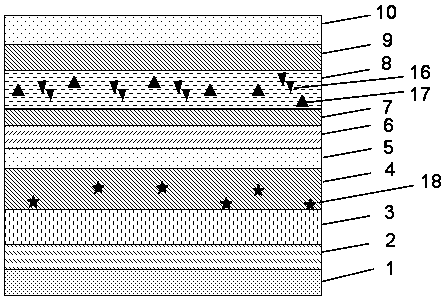

[0064] The device structure of the organic solar cell prepared by the above method is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com