Support structure for planar reflection mirror on movement platform

A technology for plane mirrors and support structures, applied in installation, optics, instruments, etc., can solve the problems of increasing load weight and volume, not being able to guarantee the surface shape error of plane mirrors, and not being able to adapt to support methods, etc., to achieve the effect of reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

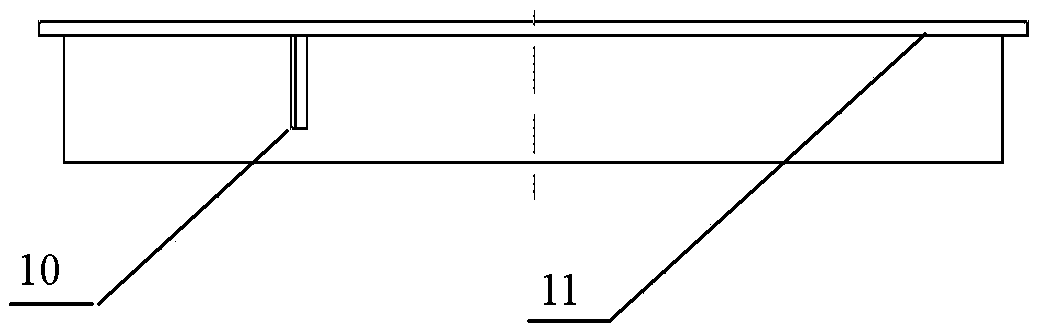

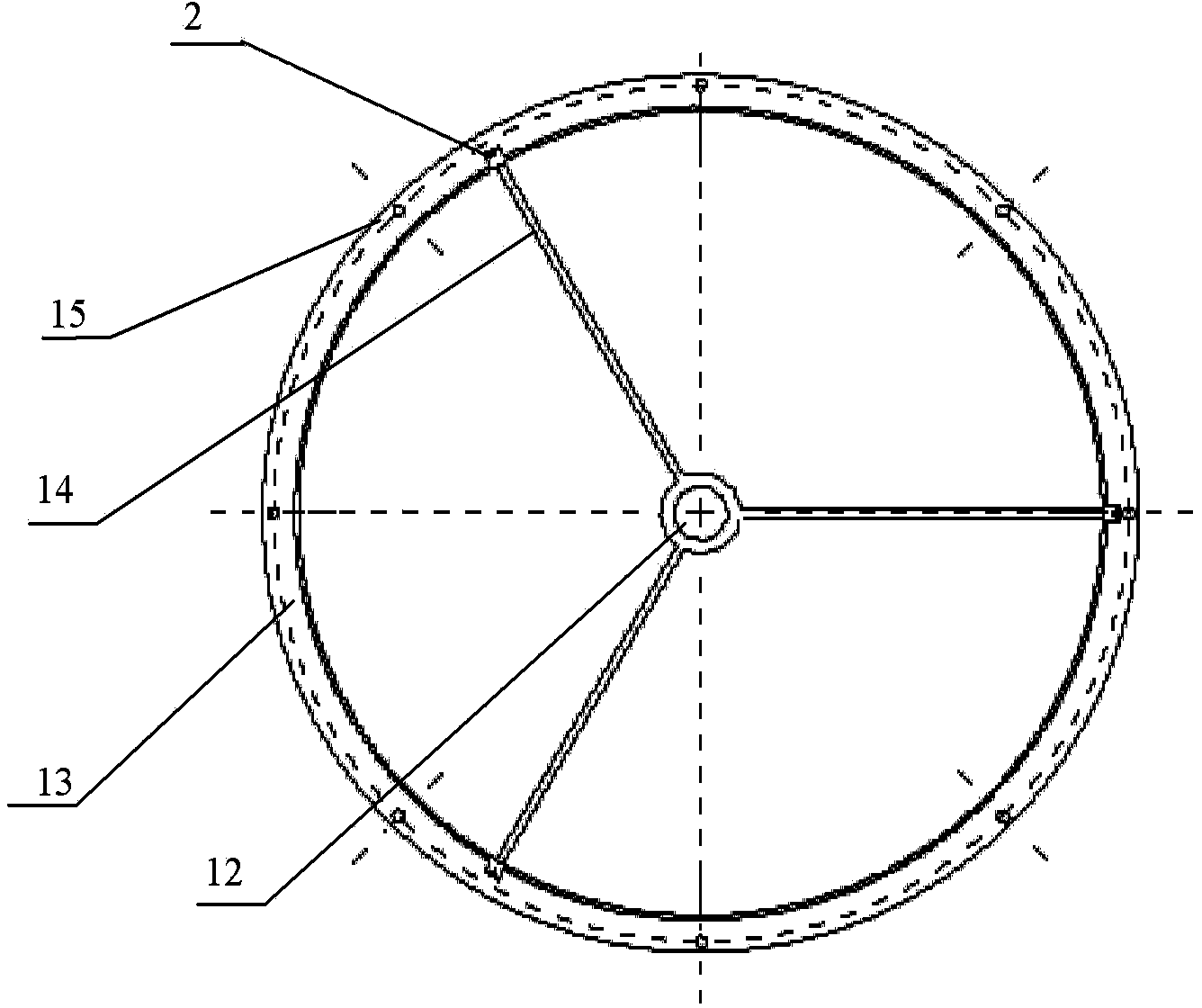

[0020] Such as figure 1 with Figure 10 Shown is the supporting structure of the flat mirror 9 on the moving platform, which mainly consists of a flange ring 1, a pressing block 2, a sleeve 3, a top plate 4, a locking ring 5, a ball head rod 6, a linear motor 7, and a plurality of screws 8 It is composed of a plane reflector 9; the back of the plane reflector 9 is supported on the flange ring 1 by edge support, and the plane reflector 9 is pressed by a plurality of pressing blocks 2, and the pressing blocks 2 are fixed on the flange by screws 8 on the ring 1; the sleeve 3 is fixed on the back of the plane reflector 9 by gluing, and the top plate 4 is fixedly connected with the sleeve 3 by screws; Tighten the ball stud 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com