Water jet propulsion pump

A technology of water jet propulsion and pump body, which is applied in the direction of ship propulsion, propulsion parts, pumps, etc. It can solve the problems of strong gear mesh vibration, power source erosion and water immersion, position deviation, etc., to ensure working noise and high efficiency and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

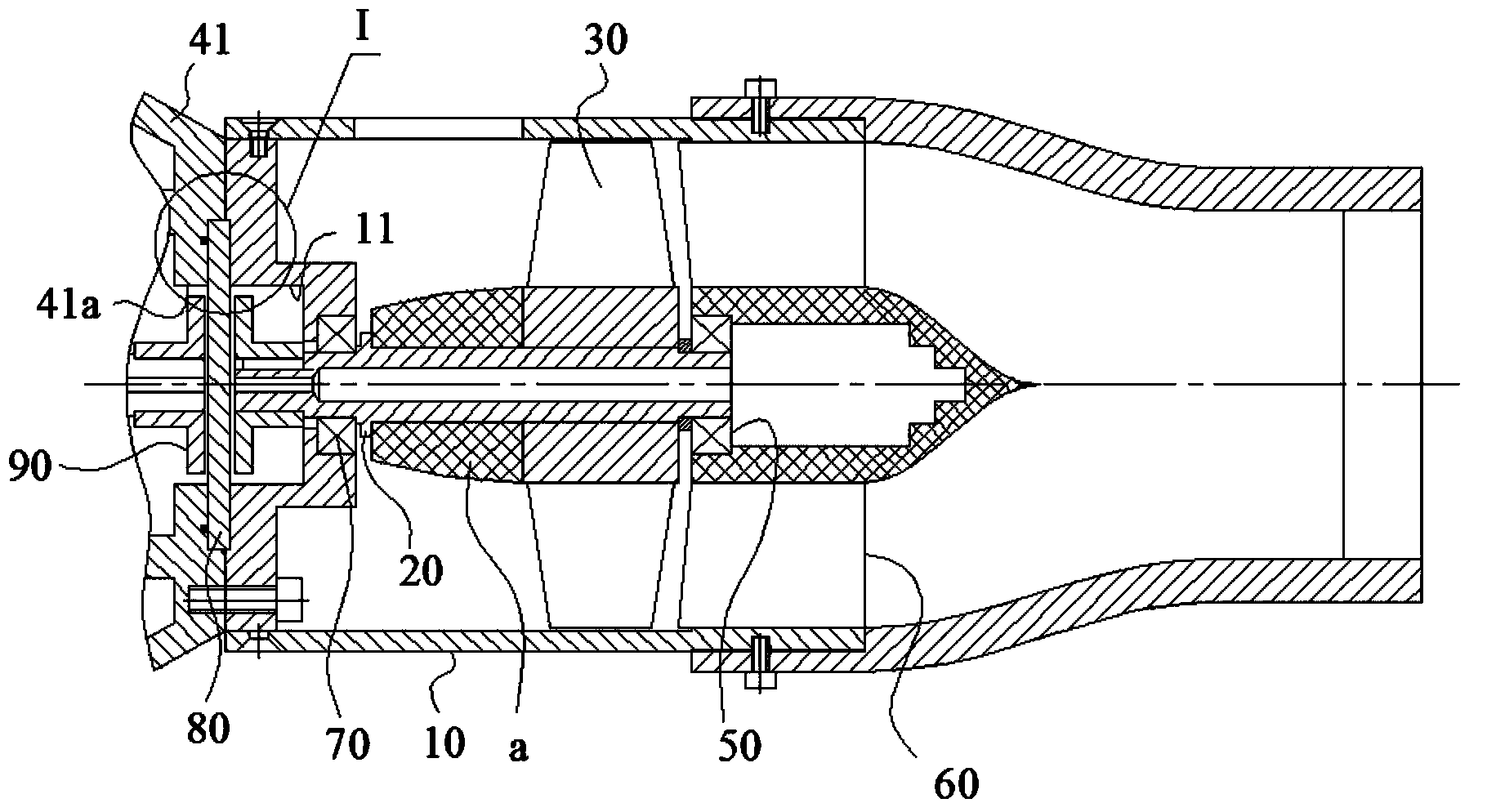

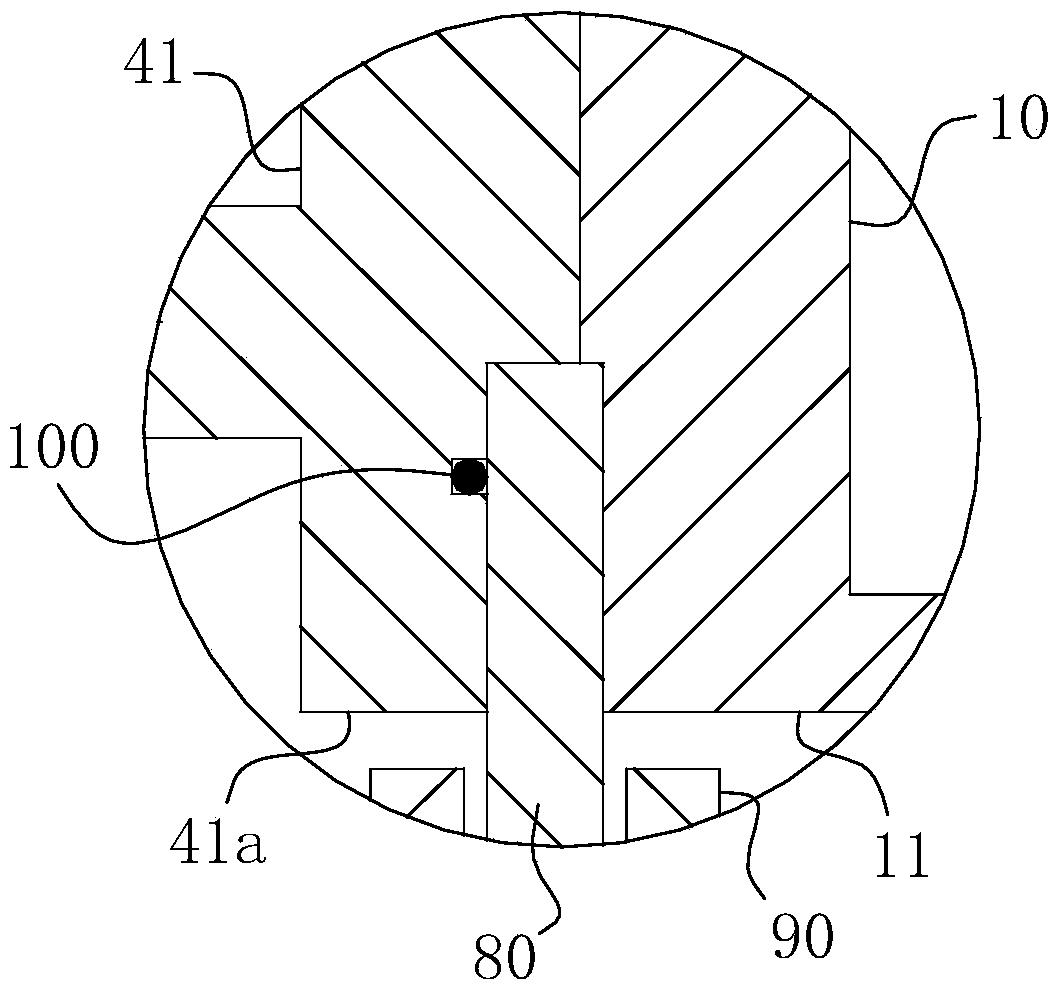

[0028] For ease of understanding, combine here Figure 1-2 The overall assembly components and work flow of the water jet propulsion pump are described as follows:

[0029] Such as figure 1 The structure of the water jet propulsion pump shown has a hollow straight barrel-shaped pump body 10 as its main body shell, in which a pump shaft 20 is arranged, and the axis of the pump shaft 20 is arranged coaxially with the axis of the pump body 10; the length of the pump shaft 20 is shorter than that of the pump The length of the body 10; one end of the pump shaft 20 and the bottom surface of the barrel of the pump body 10 form a rotation, that is, a bearing matching structure, to form the power end of the pump shaft 20, and the other end of the pump shaft 20 extends along its axis and is similar to the front guide The bearing assembly 50 at the shaft of the blade 60 forms a bearing fit, thereby forming a simply supported beam fixed structure relative to the pump shaft 20. The power sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com