Multistage compression energy-saving utilization technology of overall fuel gas type natural gas compressor

A natural gas and gas-fired technology, applied to combustion engines, internal combustion piston engines, mining fluids, etc., can solve the problems of low work efficiency and high energy consumption of reciprocating compressors, and achieve the effects of improving work efficiency, improving unit efficiency and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

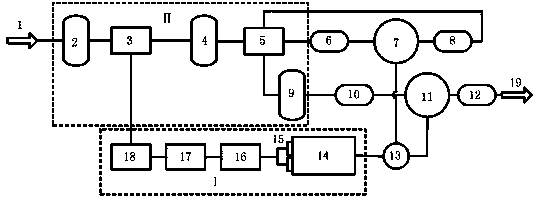

[0010] The multi-stage compression energy-saving utilization technology of the integrated gas-fired natural gas compressor of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] The invention is an energy-saving method for improving the working efficiency of the unit by using the residual energy of the high-temperature tail gas discharged from the gas engine of the integral gas-type natural gas compressor unit and re-separating the gas from the manifold at a low temperature, mainly including a gas engine exhaust residual energy utilization system of the unit system Ⅰ and natural gas separation and heat exchange system Ⅱ. Natural gas compressor unit system Gas engine tail gas residual energy utilization system I is composed of gas engine 14, tail gas exhaust pipeline 15, heat exchange evaporator 16, air motor 17 and refrigeration equipment 18 in series; natural gas separation and heat exchange system II is composed of gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com