Concrete-filled square steel tube and steel beam semi-rigid reinforcing joint for preventing progressive collapse

A square steel pipe and concrete technology, applied in building maintenance, construction, building construction, etc., can solve the problems of complex construction and high cost, and achieve the effect of clear and reliable force transmission route, low cost, and avoidance of local buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

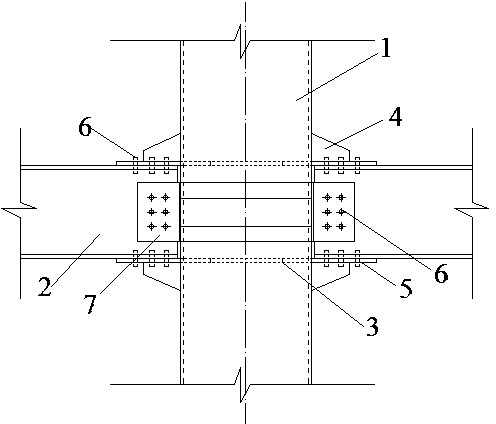

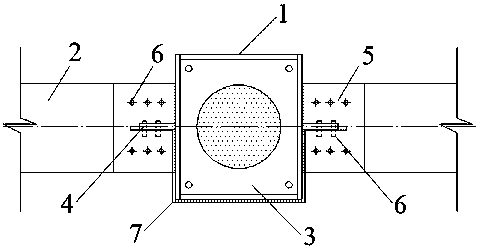

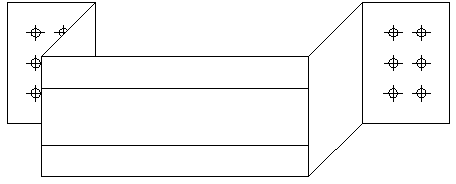

[0020] Such as figure 1 with figure 2 As shown, the present invention comprises a square steel tube concrete column 1 and an I-shaped steel beam 2, and internal partitions 3 are respectively established in the square steel tube walls corresponding to the upper and lower flanges of the steel beam 2, and on the I-shaped steel beam 2 , and the square steel pipe wall at the lower flange place are respectively provided with a horizontal connecting plate 5, and the horizontal connecting plate 5 is fixed on the flange of the I-shaped steel beam 2 by high-strength bolts 6; Stiffeners 4 are respectively arranged on the walls of the square steel tubes, and together with the horizontal connecting plates 5, corner connectors are welded outside the wall of the steel tube concrete column 1; two U-shaped steel connecting plates 7 are bypassed and welded to On the wall, the U-shaped steel connecting plate 7 is also used as a vertical connecting plate, and is fixed with the I-shaped steel be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com