Semi-rigid pipe joints for immersed tunnels

An immersed tunnel, semi-rigid technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of large longitudinal stress on the pipe joint structure, weak shear resistance and waterproofing, and risk of water blocking, etc. Improve shear resistance, improve force and deformation increase, and prevent over-opening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

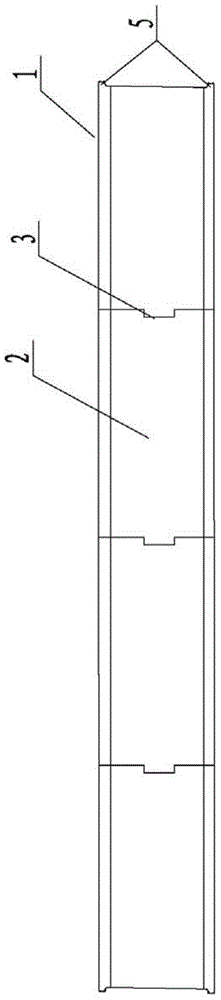

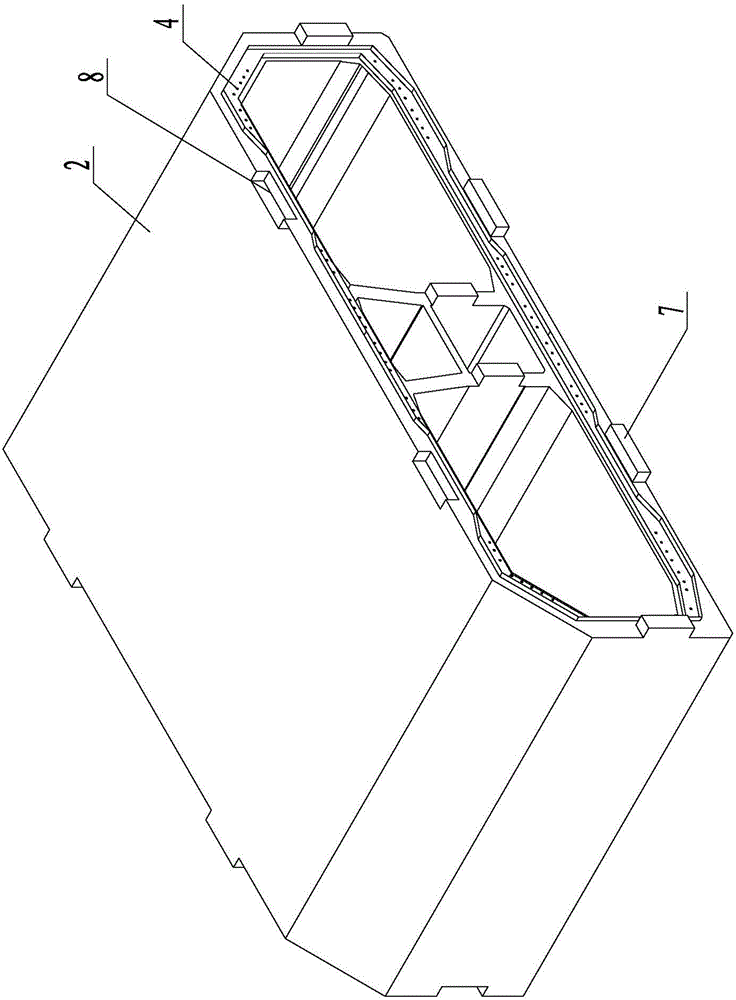

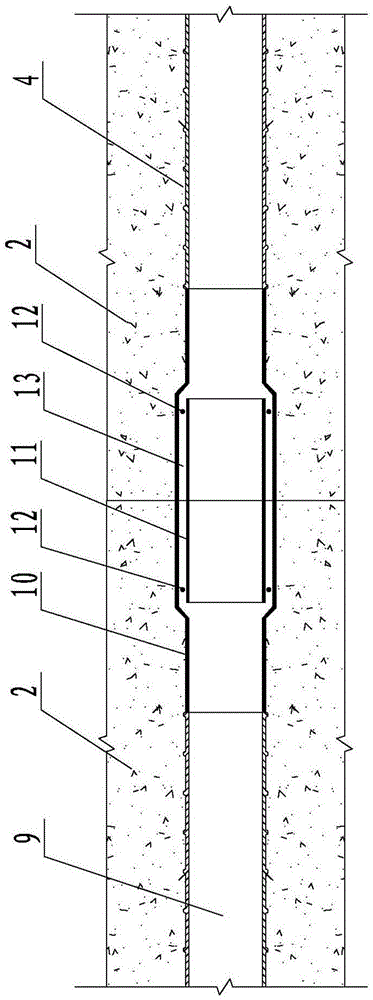

[0027] see figure 1 , figure 2 , image 3 , Figure 4 As shown, a semi-rigid pipe joint for an immersed tube tunnel of the present invention is characterized in that it includes a pipe joint main body 1, which is formed by splicing a plurality of pipe joint segments 2 connected end to end, and each Tenon-convex structures 3 are provided between the pipe joint segments; a plurality of prestressed pipes 4 are evenly arranged in the pipe joint body along its circumference; the prestressed pipes run through the pipe joint body longitudinally ; The prestressed pipeline is correspondingly penetrated with prestressed steel beams (not shown in the figure) for adjusting the prestressed degree of each of the pipe sections; Pipe joints 5 for butt-joint pipe joints; prestressed anchors 6 for anchoring the prestressed steel tendons are also provided on both ends of the pipe joint body, wherein, the two ends of each prestressed steel tendon pass through the The parts outside the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com