Marine kitchen garbage treatment device

A technology of kitchen garbage and treatment equipment, which is applied in the field of biodigestion treatment equipment, harmless, ship kitchen garbage volume reduction, and can solve the problems of inconvenient operation, pollution of ship environment, low garbage volume reduction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

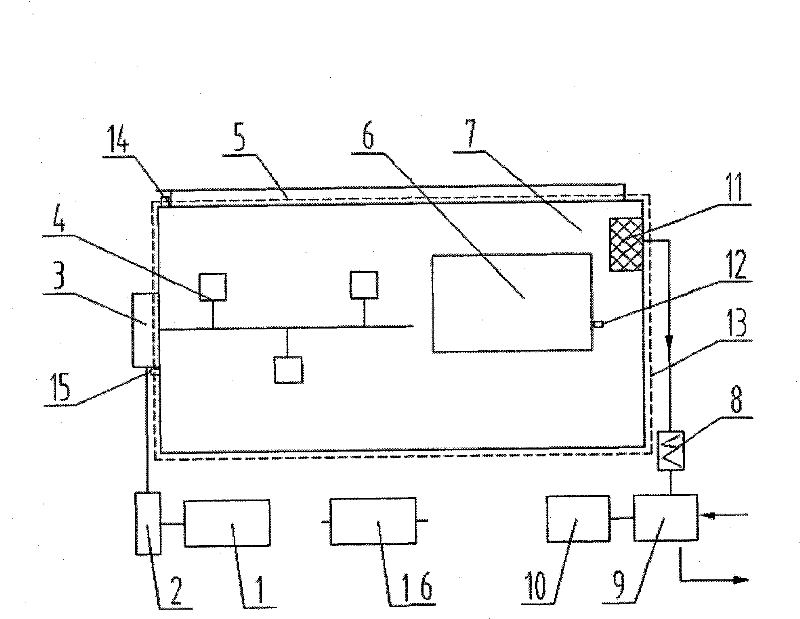

[0024] figure 1 As shown, the marine kitchen waste treatment device mainly includes a motor 1, a worm gear reducer 2, a belt drive 3, a mixer 4, a body 7, a filter 11, an electric heating cable 13, a three-way catalytic converter 8, an inducer 9, and a fan 10 And automatic control box 16. The body 7 is provided with an agitator 4, the power source of the agitator 4 is provided by the motor 1 through a worm gear reducer and a belt drive 3 at one end of the body 1, and the belt drive 3 is provided with a cam velocimeter 15; on the body 7 above the agitator 4 A feeding cover 5 is provided, a first proximity switch 14 is provided on the lower end surface of the feeding cover 5 close to the body 1, a discharge cover 6 is provided on the side wall of the body 7, and a second proximity switch 14 is provided on the end surface of the discharge cover 6 close to the body 1. Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com