Prefabricated slab vibration tamping device

A technology of prefabricated panels and vibrating motors, applied in the field of industrial manufacturing, can solve problems such as easy generation of air bubbles, insufficient compactness inside, and unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

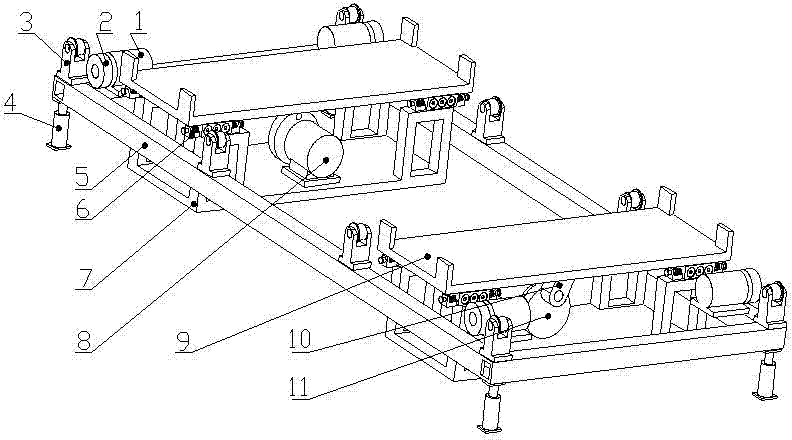

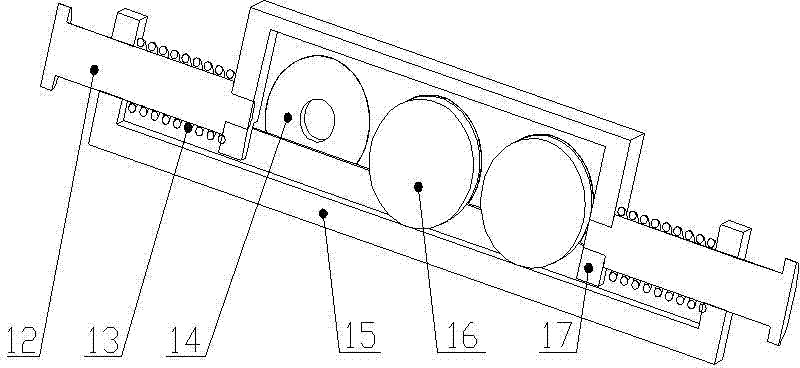

[0014] The device of the present invention is used for vibration filling of prefabricated slabs after concrete pouring, and the device includes a transmission motor 1, a rubber roller 2, a driven roller 3, a lifting cylinder 4, a general support 5, an elastic support 6, a vibrating bottom plate 7, and a vibrating motor 8. It consists of a vibrating support plate 9, a vibrating rocker 10 and a vibrating crank 11. Four lifting oil cylinders 4 are fixed on the ground and are respectively supported at four corners of the universal support 5 . On the longitudinal frame of the universal support 5, eight groups of driven rollers 3 are evenly installed by bolts to support the prefabricated platen. The rubber roller 2 and the drive motor 1 form the active rollers for transmitting the prefabricated platen. Four groups of active rollers are fixed on the four corners of the universal support 5, and the rubber rollers 2 of the active rollers are slightly higher than the driven rollers 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com