UV grinding tool grease and personalized grinding tool production method

A production method and technology of abrasive tools, applied in the direction of grinding devices, manufacturing tools, grinding/polishing equipment, etc., can solve the problems that manufacturers cannot provide or are unwilling to provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

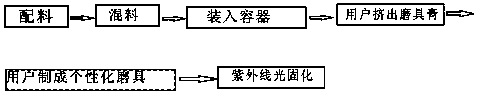

[0017] The present invention is described in further detail with embodiment in conjunction with accompanying drawing

[0018] For example, mix the following components evenly: white corundum 60-70%; Chiba hyperbranched resin 12-15%; Poma monofunctional UV resin 10-12%; active monomer hydroxyethyl methyl propionate 6-- 12%; Huatai photoinitiator 2~4%; Dow Corning 6030 coupling agent 0.4-0.8%; put into UV abrasive paste container. After the user buys back the UV abrasive paste, if it is used as an abrasive paste, within the validity period (2-4 years), squeeze the container and squeeze out the abrasive paste under the condition of no ultraviolet light, and it can be used directly ; If it is to be used as a grinding wheel, grinding head, grinding bar, etc., at any time during the validity period, under the condition of no ultraviolet light, fill the extruded UV abrasive paste into the transparent rubber abrasive provided by the manufacturer In the mold on the board (there are do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com