Nested type three-phase mixing nozzle of water, oil and gas and nozzle system with same

A mixing nozzle and nested technology, which is applied in the direction of spraying devices, liquid spraying devices, maintenance and safety accessories, etc., can solve problems such as incomplete mixing, affecting the health of workers and the environment, and complex processes, and achieve the goal of improving surface finish Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

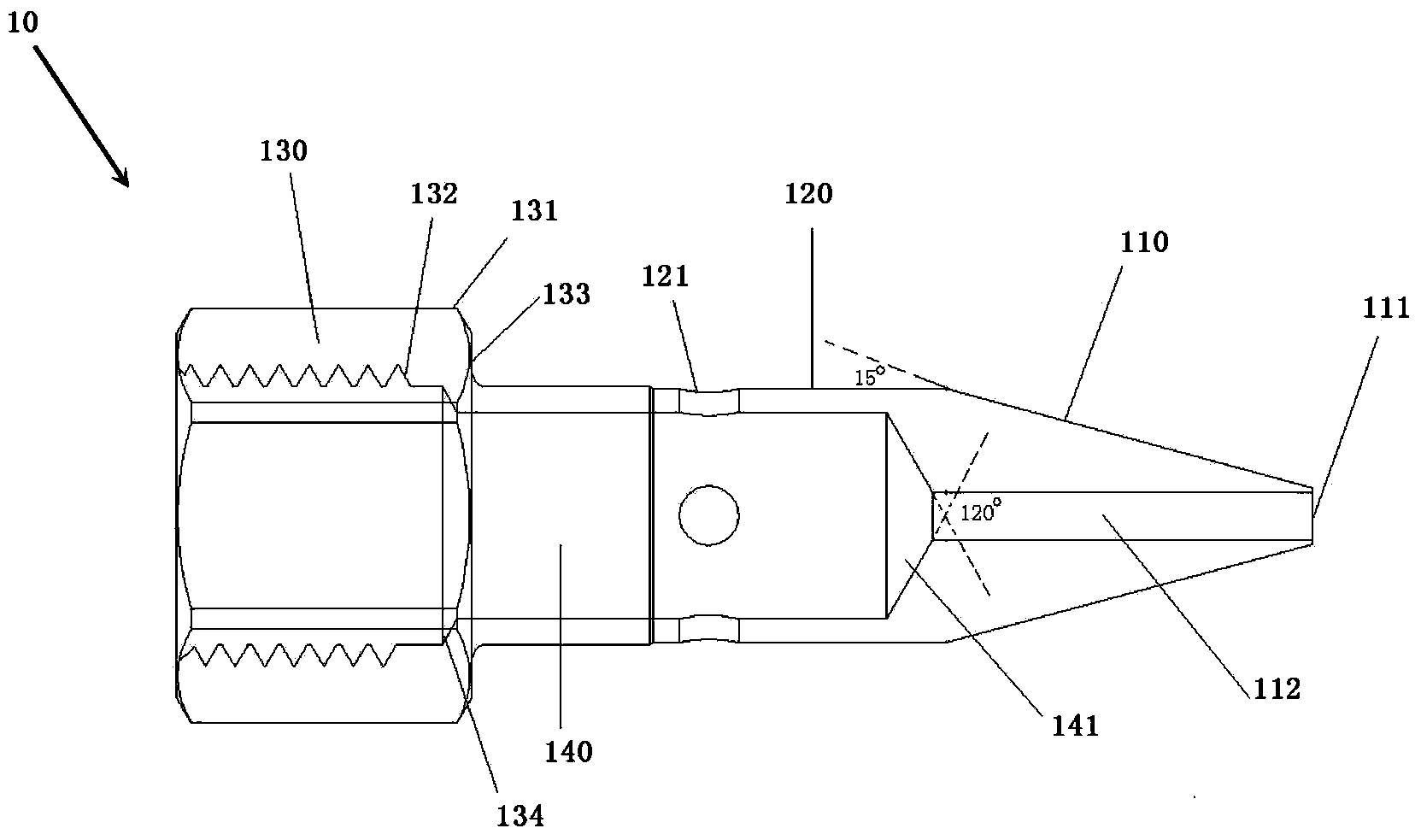

[0073] Now, the present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0074] like figure 1 As shown, the present embodiment provides a nozzle system 100 including a nested water, oil and gas three-phase mixing nozzle, including a nozzle body 10 , a nesting ring 20 , a mixing chamber 30 and a gas-liquid input mechanism 40 .

[0075] like figure 1 and 2 As shown, the nozzle body 10 includes a head 110 , a middle 120 and a bottom 130 . The head 110 of the nozzle body 10 is a cone, and the top is provided with an injection hole 111; the middle part 120 of the nozzle body 10 is a cylinder, and four air holes 121 are uniformly arranged on the cylinder; the bottom 130 of the nozzle body 10 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com