Double-head phase friction welding machine with single-spindle box once loaded

A friction welding machine and single-spindle technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as unsatisfactory problems and inability to realize fixed-phase welding, so as to reduce investment, improve welding production efficiency, and avoid loss of precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

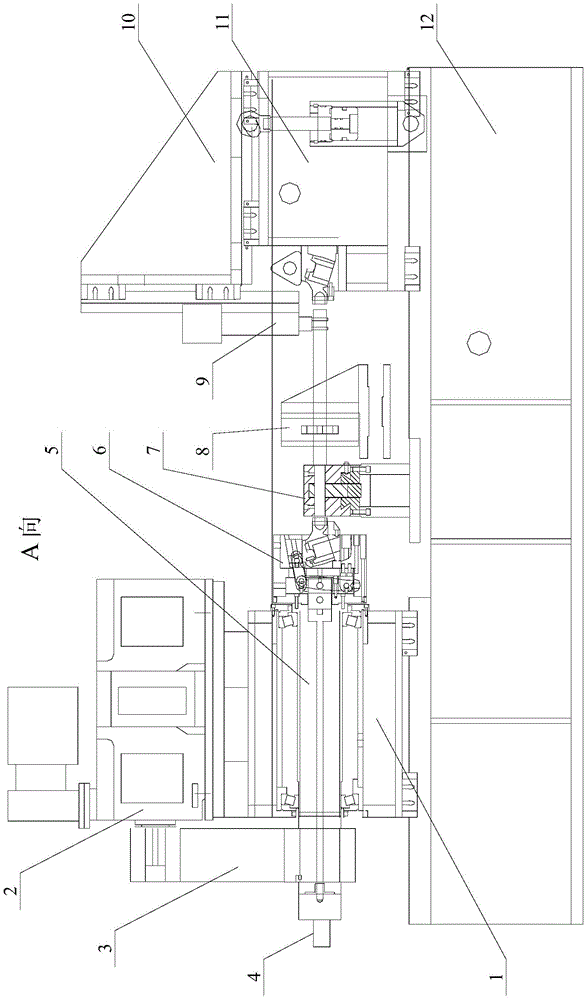

Embodiment 1

[0019] Embodiment 1: Two workpieces are welded at one time according to a fixed phase relationship.

[0020] Before friction welding, the phase is set on the touch screen in the electronic control system, the spindle 5 and the rotary fixture 6 stop at the initial phase, and the two workpieces are respectively clamped in the rotary fixture 6 and the fixed fixture 7 according to the fixed initial phase relationship. Center frame 8 is used for auxiliary positioning, and roller center frame 9 is suspended in the air. After moving, the pushing device 10 directly pushes against the workpiece in the fixing fixture 7 .

[0021] Start the hydraulic station and the DC motor, the workpiece in the rotary fixture 6 rotates under the drive of the DC motor assembly 2 and the synchronous pulley transmission mechanism 3, the other workpiece is clamped by the fixed fixture 7, and the headstock 1 is driven by the hydraulic system Move to the workpiece fixed in the fixed fixture 7, the spindle b...

Embodiment 2

[0022] Embodiment 2: Three workpieces are welded twice according to a fixed phase relationship.

[0023] When two identical workpieces are required to be welded symmetrically at both ends of the third workpiece, the three workpieces are clamped at one time according to the fixed phase relationship, and the double-headed workpieces with fixed phase angle requirements can be welded twice with a single headstock drive.

[0024] Before friction welding, the phase is set on the touch screen in the electronic control system, the spindle 5 and the rotating fixture 6 stop at the initial phase, and the two workpieces are respectively clamped in the rotating fixture 6 and the fixed fixture 7 according to the fixed initial phase relationship. Center frame 8 is used for auxiliary positioning, and roller center frame 9 is suspended in the air. The workpiece three in the lifting device 10 is positioned and clamped by the workpiece positioning and clamping device 11 after moving, and direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com