Mechanical clamping type inner thread turning cutter

A thread turning and clamping technology, which is applied in thread cutting tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult thread processing, low cost, large diameter, etc., and achieves good results, low thread surface roughness, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

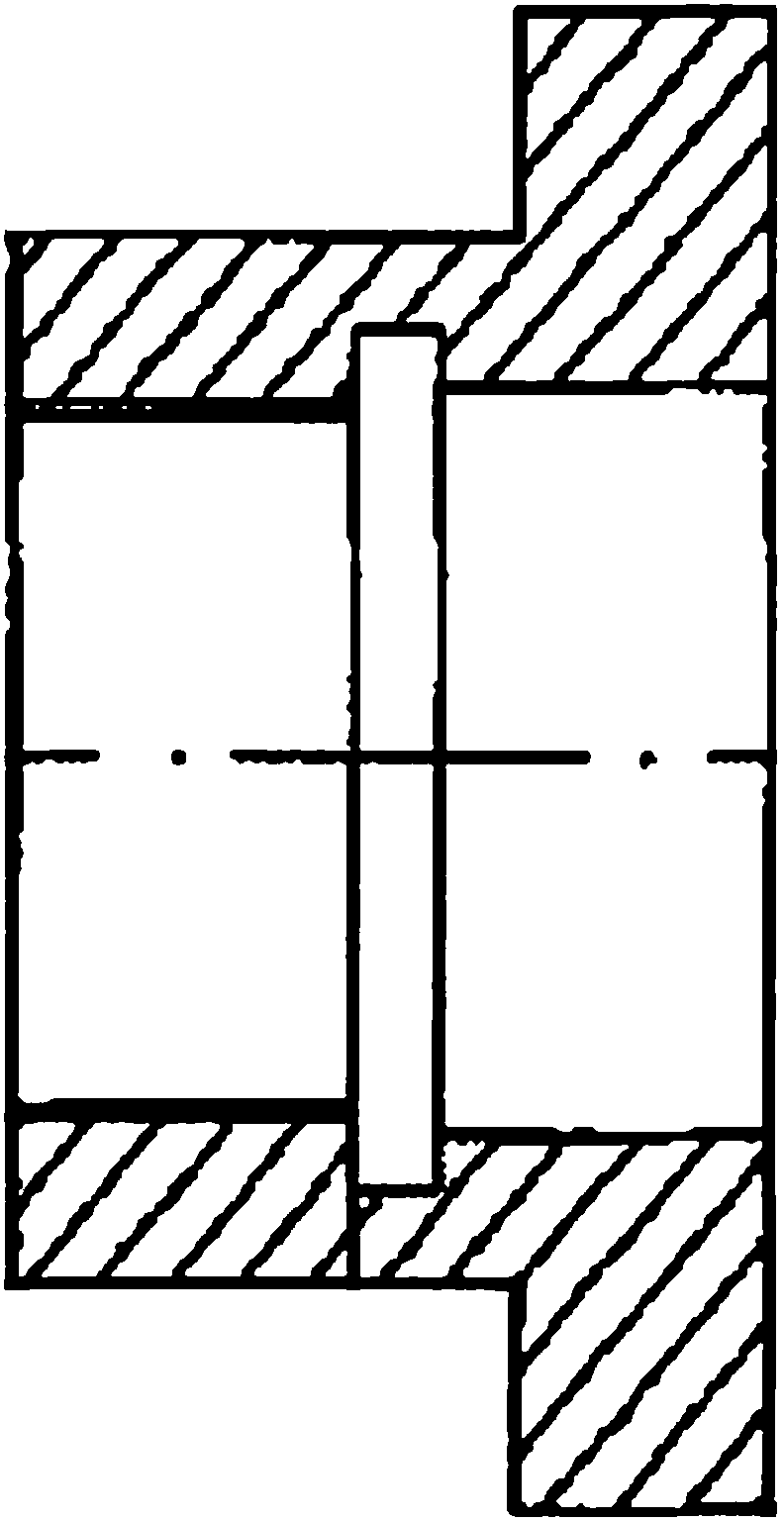

[0010] As shown in the figure, the clamp-type internal thread turning tool of the present invention includes a cylindrical cutter bar 3, one end of the cutter bar 3 is provided with a cutter head 1, and a blade 4 is fixedly provided on the cutter head 1. It is fixed on the cutter head 1 by a compression screw 2. The tip of the blade 4 is 0.3-0.5mm higher than the spindle center of the tool bar 3.

[0011] The specific installation method before the tool is used is to first make the blade 4 side flat on the positioning surface of the tool bar 3, tighten the fastening screw 2, so that the positioning surface on the side of the cutter head 1 presses the blade 4, so that the blade 4 is tightened. It is fixed in the clamping and positioning surface between the cutter head 1 and the cutter bar 3. When the blade needs to be replaced, just loosen the fastening screw 2 and remove the blade 4. In order to improve production efficiency, the tool structure adopts a symmetrical design. Two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com