Regeneration system of used clay sand

A technology for the regeneration of used sand and clay, which is used in foundry molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc. It can solve the problems of incomplete regeneration, environmental pollution, waste of resources, etc. The effect of reducing production cost and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

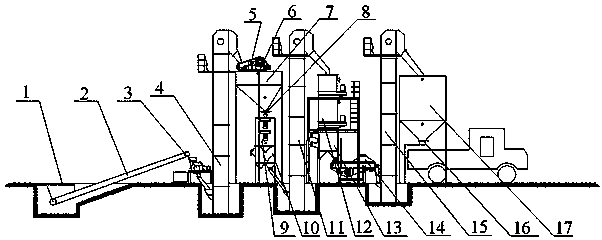

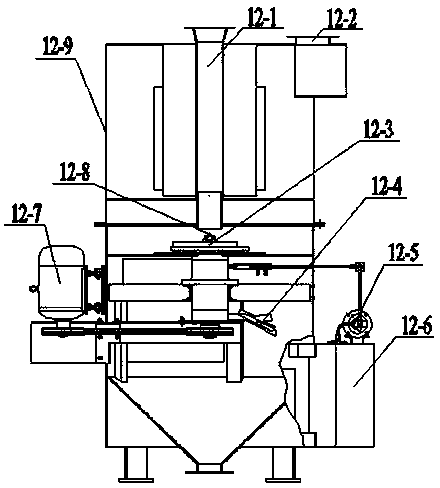

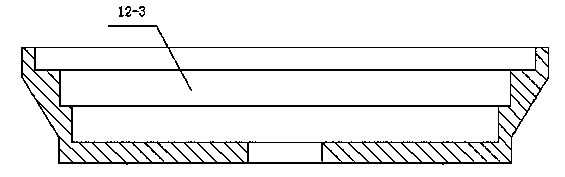

[0024] refer to Figure 1-Figure 3 , this embodiment is a regeneration system for old clay sand, which is mainly composed of a belt conveyor with magnetic separation, a chip crusher, a bucket elevator, a linear vibrating sand screen machine, a storage device, a centrifugal regenerator, and air separation It is composed of device and vortex regenerator.

[0025] The end of the belt conveyor 2 with magnetic separation is connected to the feed port of the impact crusher 3, the primary bucket elevator 4 is connected to the discharge port of the chip crusher 3 and the primary linear vibrating screen sand machine 5, The middle sand hopper 7 is located below the primary linear vibrating screen sand machine 5, the feed port of the centrifugal regenerator 9 is connected to the discharge port of the intermediate sand hopper 7, the primary wind separator 10 is located under the centrifugal regenerator 9, and the secondary bucket type Elevator 11 is connected to the outlet of centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com