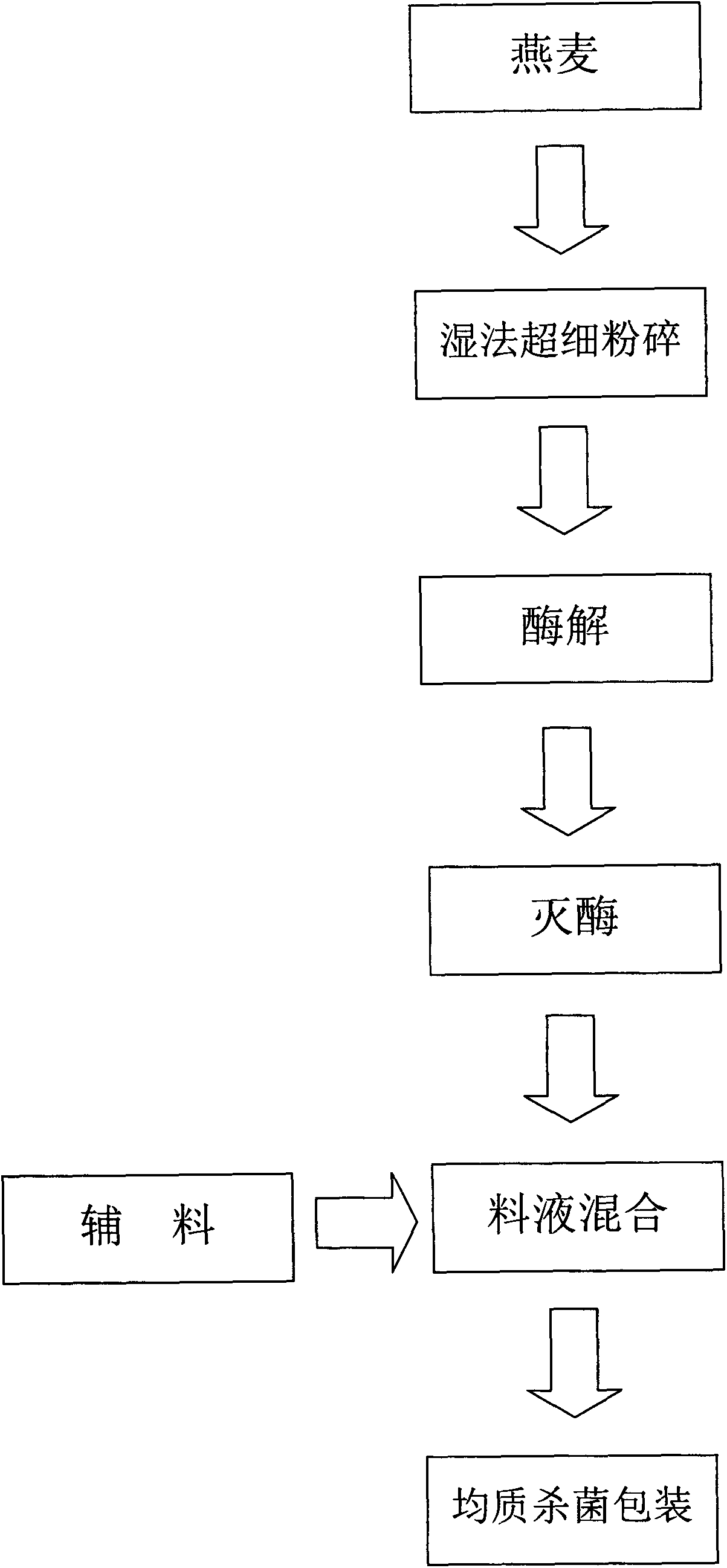

Method for preparing whole oat healthy drink through wet process ultrafine grinding

A wet ultra-fine, healthy beverage technology, applied in the field of grain deep processing, can solve the problems of unnatural taste, unstable system, low utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Get 500g of oats, add 2500g of soft water to carry out wet superfine grinding, then pass through a 300 mesh sieve, add soft water 5 times the weight of oat raw material to the slurry after superfine grinding, boil to make the starch in it gelatinize completely, Then cool to 50-60°C, enzymolyze the obtained slurry, the enzymolysis conditions are temperature 55°C, ph is neutral, add medium temperature α-amylase 15u / g raw material, enzymolysis 30min, then add β-amylase 100u / g g raw material, enzymatic hydrolysis for 30min; then add glucose isomerase 50u / g raw material, enzymatic hydrolysis for 30min. Heat the material after enzymolysis to 90-95°C and keep it warm for 5 minutes to inactivate the enzyme. Homogenization 400MP, second-stage homogenization 200MP, the homogenized material liquid is subjected to ultra-high temperature instantaneous sterilization at a temperature of 135°C for 10s, and canning after sterilization. The percentages involved in the expe...

Embodiment 2

[0019] Embodiment 2: Get 500g of oats, add 3000g of soft water to carry out wet superfine grinding, pass through a 300 mesh sieve, add soft water with 6 times the weight of oat raw material to the slurry after superfine grinding, boil to make the starch in it fully gelatinize, and then Cool to 50-60°C, enzymolyze the obtained slurry, the enzymolysis condition is temperature 50°C, ph is neutral, add medium temperature α-amylase 20u / g raw material, enzymolysis 20min, then add β-amylase 150u / g Raw material, enzymolysis for 20min; then add glucose isomerase 80u / g raw material, enzymolysis for 20min. Heat the material after enzymolysis to 90-95°C and keep it warm for 5 minutes to inactivate the enzyme. Homogenization 400MP, second-stage homogenization 200MP, the homogenized material liquid is subjected to ultra-high temperature instantaneous sterilization at a temperature of 140°C for 5s, and canning after sterilization. The percentages involved in the experiment are all mass perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com