Super surface lens antenna based on optical transformation and manufacturing method of super surface lens antenna

An optical conversion and metasurface technology, applied in the microwave field, can solve the problems of high loss, difficult fabrication, unfavorable feeding and integration of arc-shaped focusing plane, and achieve the effect of reducing volume, good feeding and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

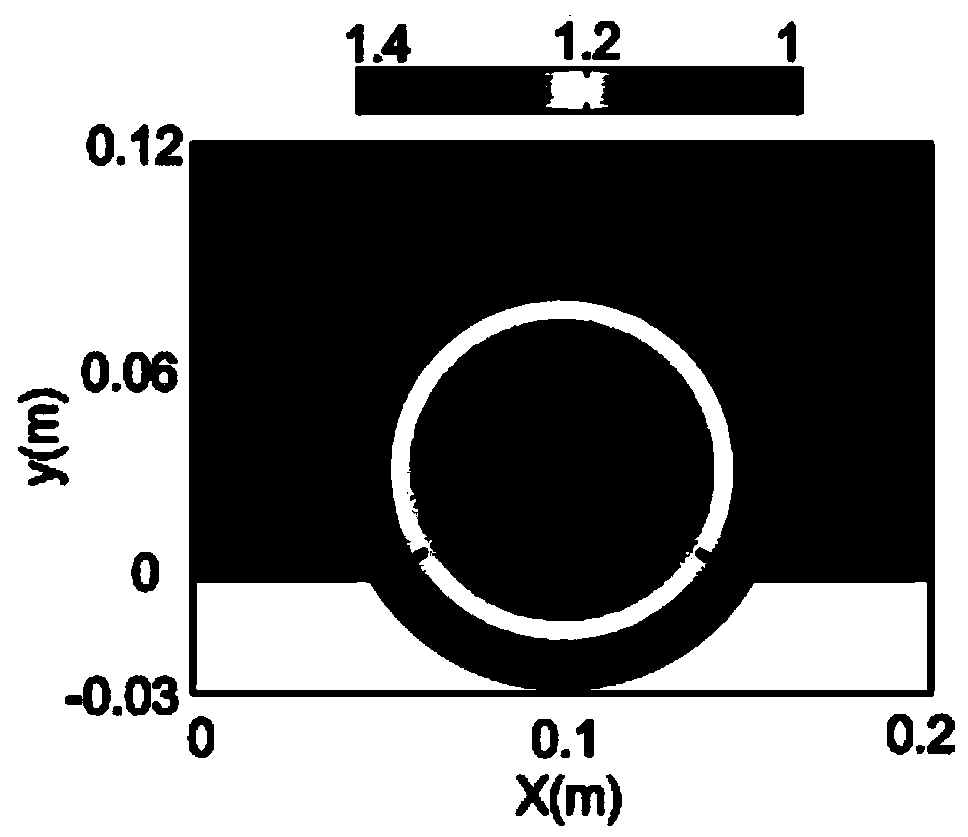

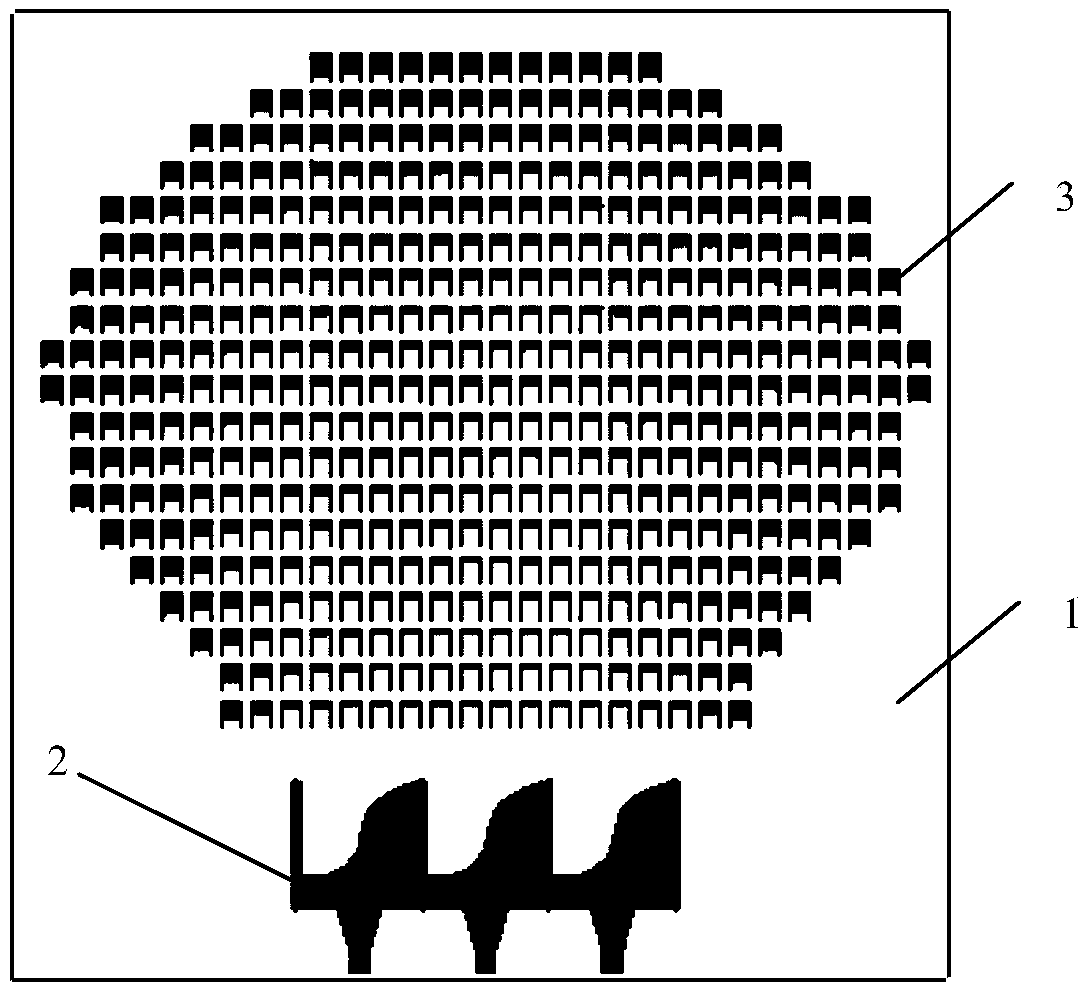

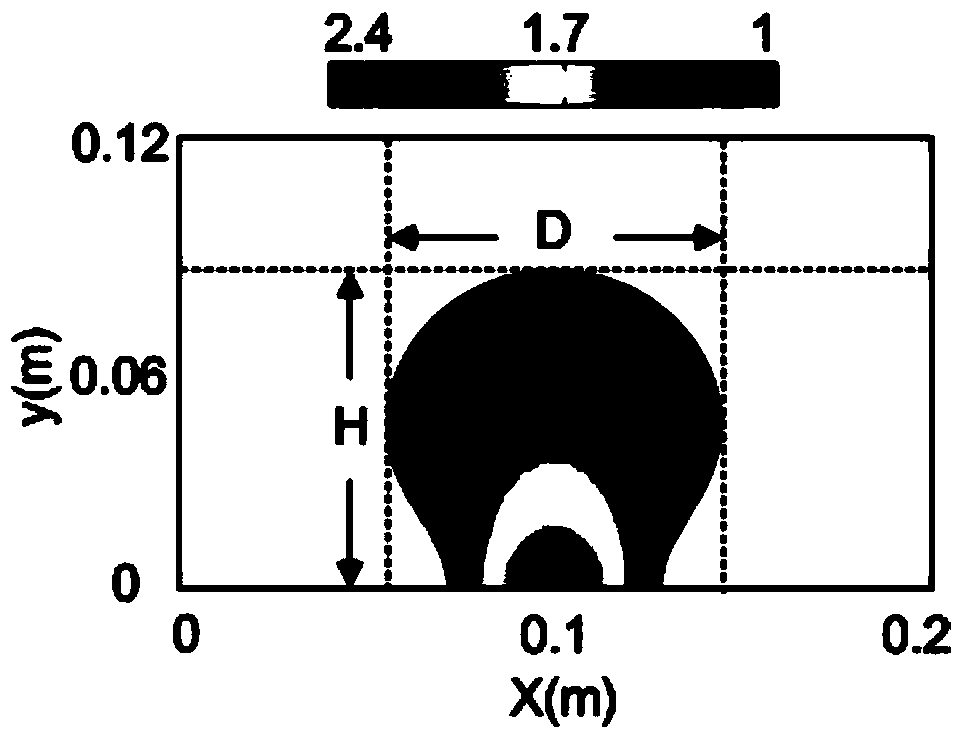

[0021] combine Figure 2 to Figure 11 The metasurface lens of the present invention is further described. Such as figure 2 As shown, the optical conversion-based metasurface lens of the present invention is mainly composed of a feed source 2 and a lens body 3 , and the lens body is integrated on a dielectric substrate 1 . The feed source 2 is composed of three positive and negative vivald antennas, and the main body of the lens is composed of discretely distributed metal U-shaped structural units. The distribution of the U-shaped structural unit is evolved from the distribution of the Lunberg lens through optical transformation. This distribution makes the arc-shaped focusing surface of the Lunberg lens flattened into a plane. Therefore, when the lens is excited by different positive and negative vivaldi antennas , the surface waves supported by the lens direct radiation in different directions.

[0022] The adjustment of the refractive index of the lens body is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com