Intelligent dynamic sealed liquid storage tank equipped with metal ripple compensator and use method of intelligent dynamic sealed liquid storage tank

A corrugated compensator, intelligent dynamic technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of time-consuming labor intensity, running, emitting, dripping, cumbersome operation, etc., to reduce working intensity and working time, and reduce moisture and air Effect of intrusion and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The intelligent dynamic sealed liquid storage tank with metal corrugated compensator of the present invention is suitable for storage and operation of liquid media that are afraid of moisture, oxidation, and light, such as transformer oil used in power systems. The following uses transformer oil as an example.

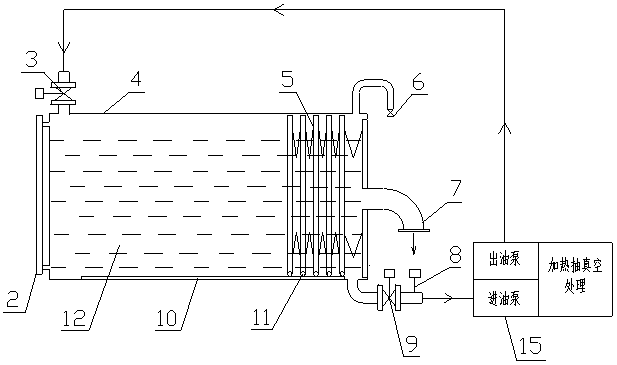

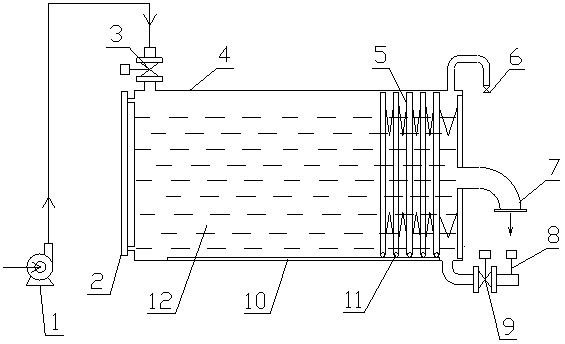

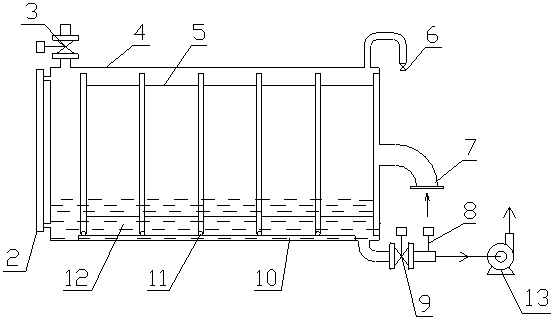

[0024] Such as Figure 1~5 As shown, an intelligent dynamic sealed liquid storage tank with a metal bellows compensator includes a liquid storage tank 4, the upper part of the liquid storage tank 4 is provided with a liquid inlet and a vent port, and the liquid inlet is provided with an inlet Liquid solenoid valve 3, the vent port is provided with a vent valve 6, the bottom of the liquid storage tank 4 is provided with a liquid outlet, and the liquid outlet is sequentially provided with a liquid outlet solenoid valve 9 and an online moisture detection device along the liquid outlet direction. 8, the metal corrugated compensator 5 capable of axial telescopic move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com