Safety protecting and hoisting device of safety valve calibration console

A safety protection and hoisting device technology, which is applied to the testing of measuring devices, instruments, and mechanical components, can solve problems such as time-consuming and laborious, potential safety hazards, and difficult calibration of large-diameter safety valves, and achieves convenience in use and reduced labor intensity , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

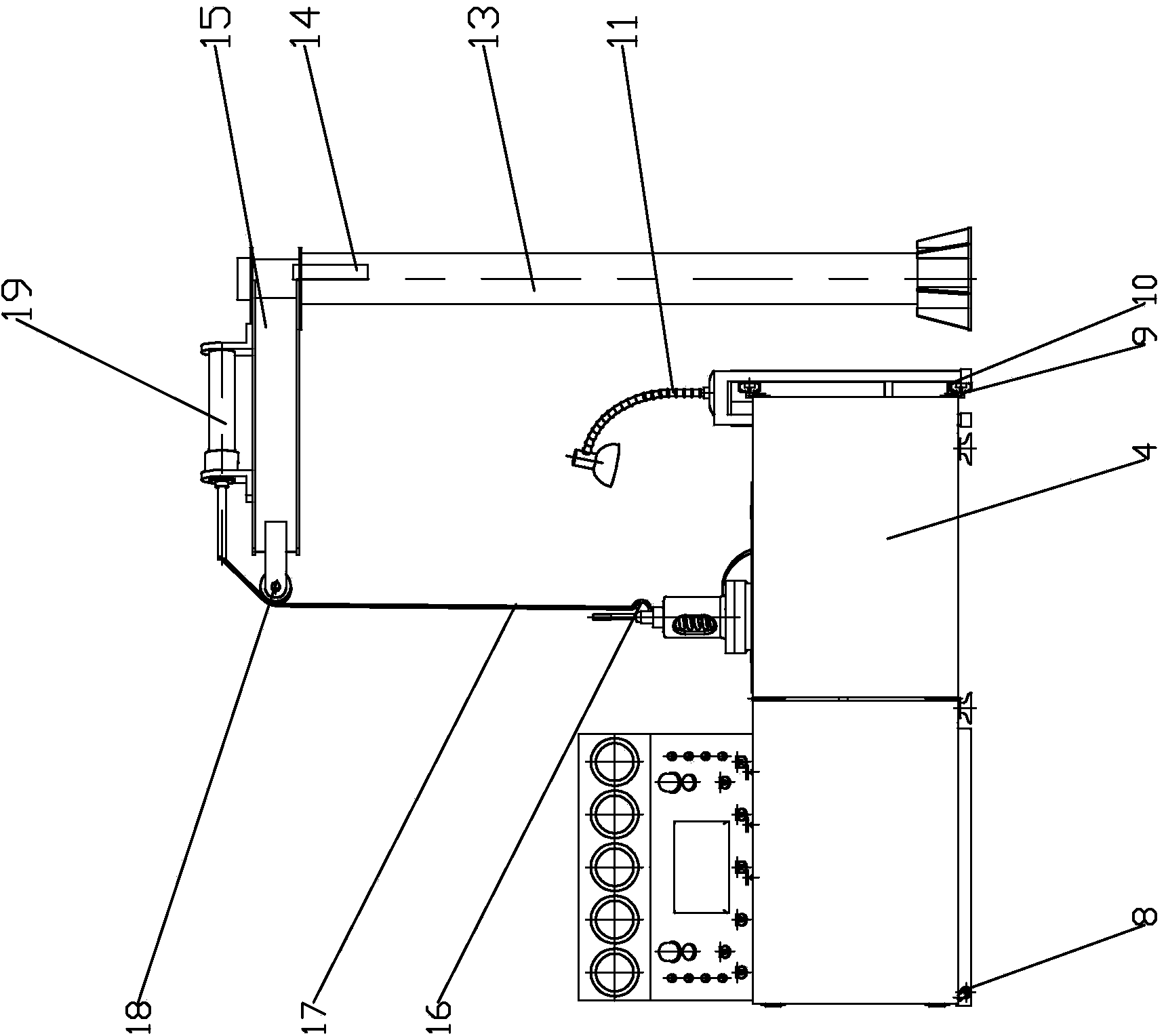

[0018] Such as Figure 1~2 As shown, the present invention mainly includes a clamping table 1, a protective wall 2, a hoisting mechanism 3 and a folding baffle mechanism 4, a protective wall 2 is provided between the clamping table 1 and the hoisting mechanism 3, and a roller guide rail is arranged in the protective wall 2 10. The folding baffle mechanism 4 is slidably installed in the roller guide rail 10 .

[0019] The hoisting mechanism 3 includes a hoisting column 13 , and the upper end of the hoisting column 13 is rotatably connected to a hoisting cantilever 15 . The hoisting column 13 is provided with stoppers 14, and the stoppers 14 are located on both sides of the hoisting cantilever 15, and are used to limit the rotational position of the hoisting cantilever 15. Hoisting cantilever 15 front ends are provided with hoisting roller 18, and hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com