Step-tooth excavating method of reciprocating impact excavators, and step-tooth reciprocating impact excavator used for realizing step-tooth excavating method

An excavator and ladder technology, which is applied in the field of machinery, can solve the problems such as the inability of continuous excavation, the falling of material layers, and the increase of the resistance of the excavation mechanism to advance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

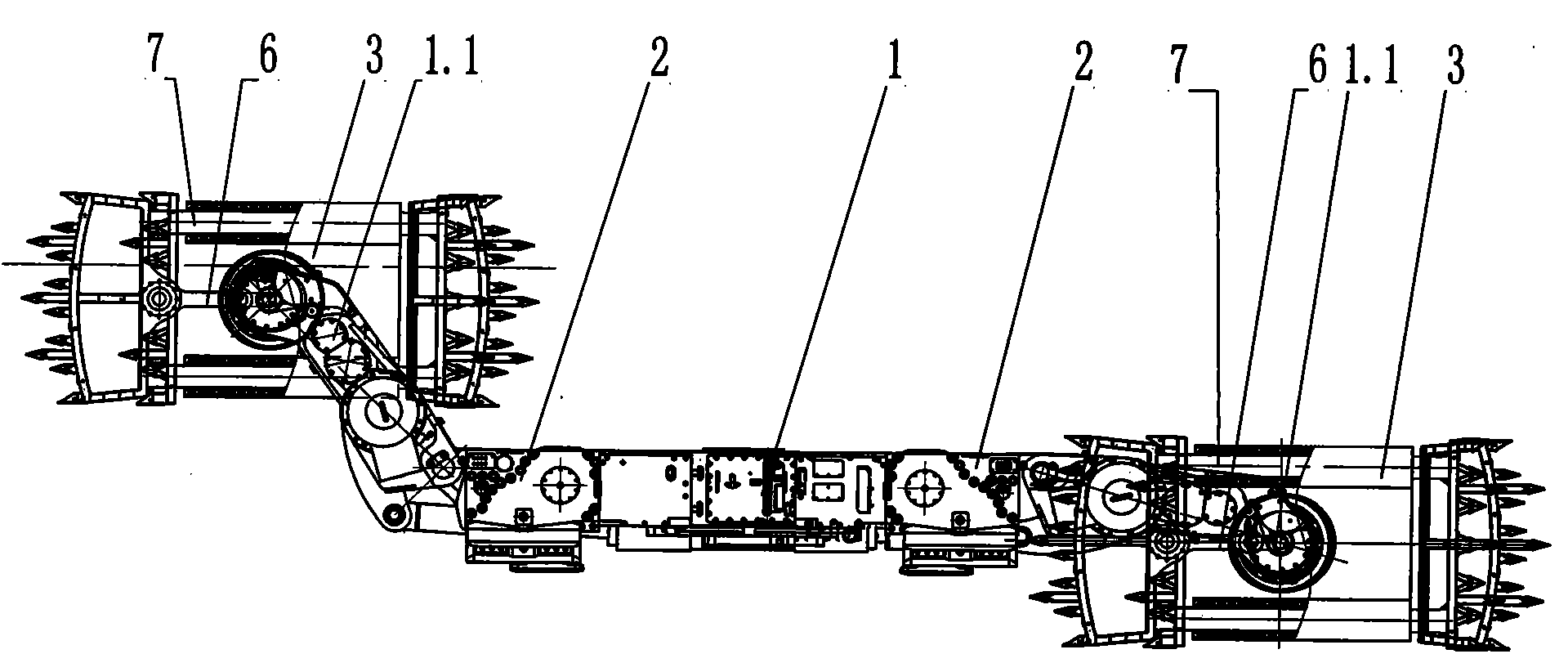

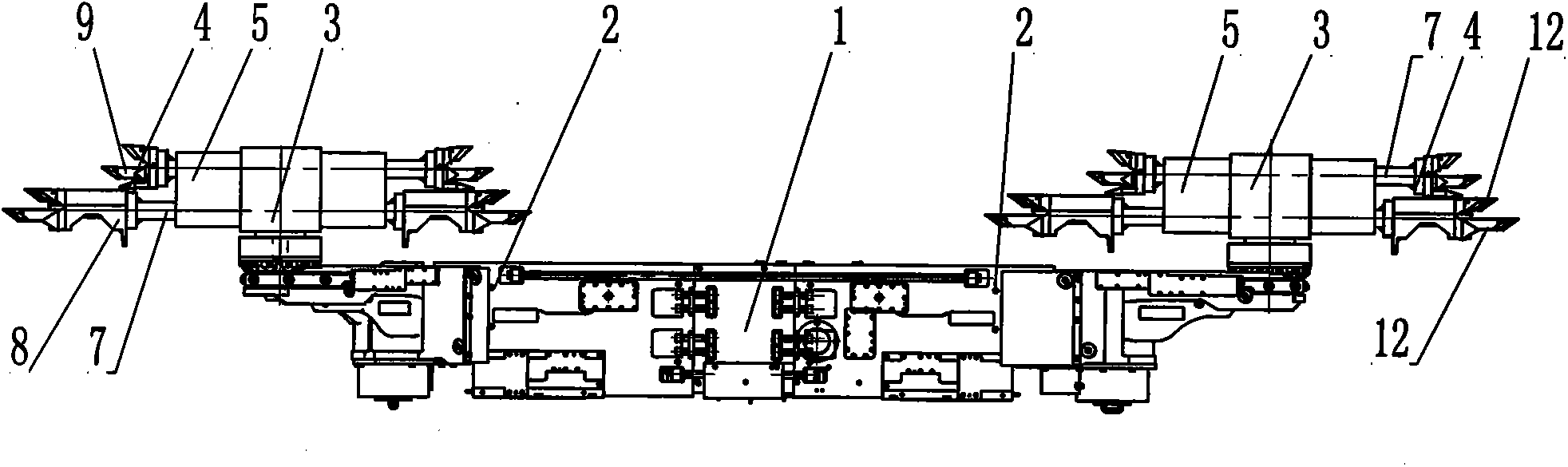

[0096] Such as Figure 1 to Figure 5 As shown, a stepped tooth reciprocating impact mining machine includes a fuselage 1, a traveling mechanism 2, etc. The stepped tooth reciprocating impact mining machine also includes an impact blanking mechanism 3, etc., and the impact blanking mechanism 3 is arranged on the fuselage 1. The traveling mechanism 2 is arranged at the lower part of the fuselage 1, and the impact blanking mechanism 3 includes a step tooth punching device 4, an impact power box 5, a power impact part 6, an impact guide 7, etc., and the power impact part 6 and the impact guide 7 are separated Or separate connection or integral type, the stepped tooth punching device 4 is connected with the power impact part 6 and / or the impact guide 7, the stepped tooth punching device 4 and the power impact part 6 are connected separately or separately or integrated The stepped tooth punching device 4 is connected separately or integrally with the impact guide 7, the power impact...

Embodiment 2

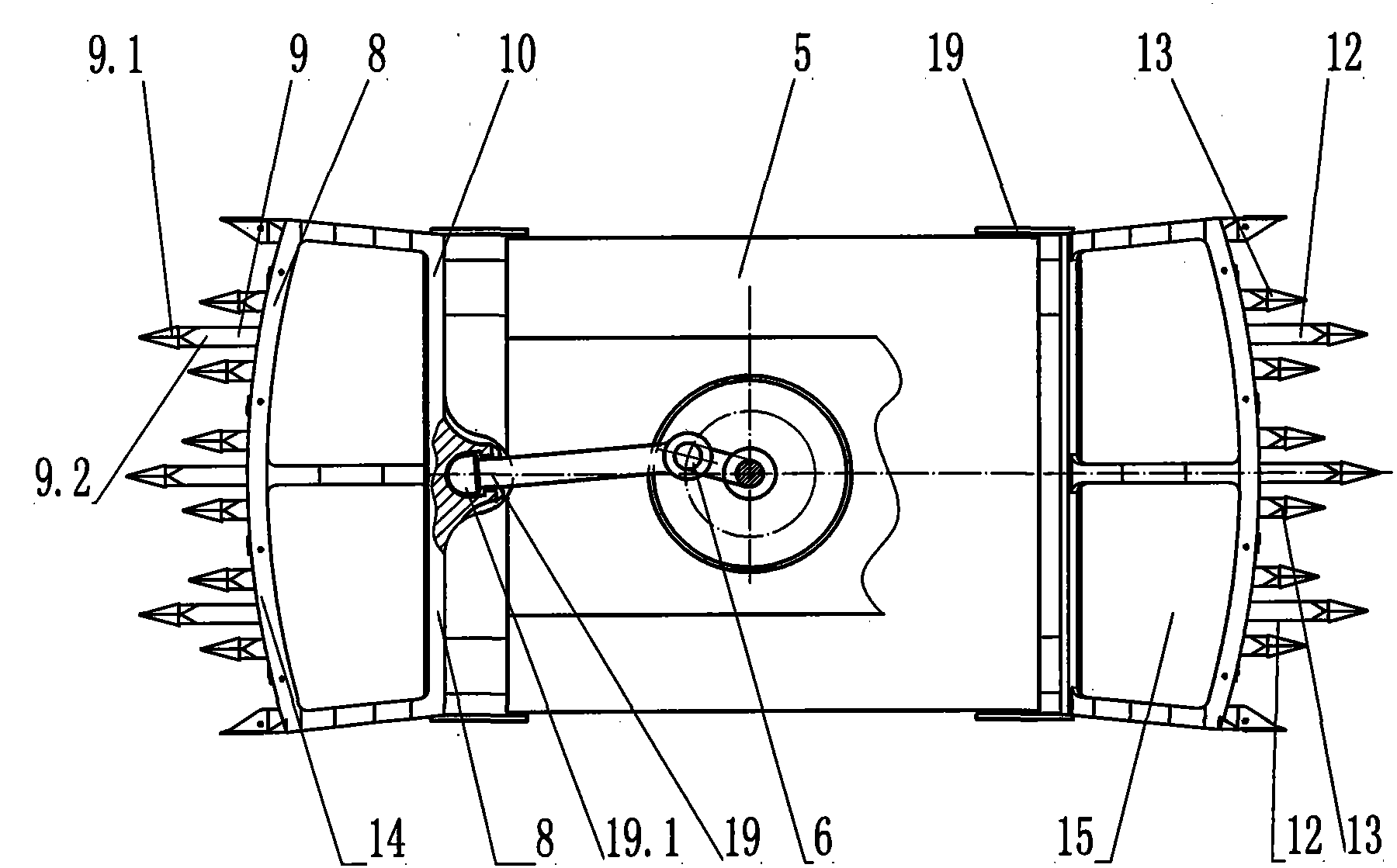

[0116] Such as Image 6 , Figure 7 As shown, the impact and blanking mechanism 3 includes a power impact member 6, etc., and an anti-damage impact driver structure 19 is provided between the power impact member 6 and the support seat 8 or on the power impact member 6. The power impact member 6 and the support seat 8 split or split connection or integrated.

[0117]The anti-damage impact driver structure 19 includes a buffer anti-damage impact driver structure 19.2, etc., the power impact member 6 drives the stepped tooth punching device 4 to impact, and the impact reaction force is applied to the anti-damage impact driver structure 19, buffering the anti-damage impact driver The structure 19.2 prevents the impact reaction force from breaking the impact and damaging the dynamic impact element 6 by cushioning.

[0118] The discharge hole 15 is a trapezoidal discharge hole, and may also be an arc discharge hole, a square discharge hole, an arch discharge hole, a triangular dis...

Embodiment 3

[0122] Such as Figure 8 , Figure 9 As shown, the stepped tooth punching device 4 includes a punching tooth 9, a support seat 8, an impact stroke protection piece 20, etc., the impact stroke protection piece 20 is arranged on the support base 8, and the impact stroke protection piece 20 is separated from the support base 8 One-piece or separate connection or one-piece type, the power impact part 6 drives the punch tooth 9 to reciprocate, and the impact stroke protection part 20 and the impact power box 5 always keep a partial overlap to prevent materials from entering the impact stroke protection part 20 and the impact power box 5, the impact travel protection member 20 is arranged around the support base 8 or partially arranged.

[0123] The impact stroke protection part can also be arranged on the impact power box, the impact stroke protection part and the impact power box are separated or separately connected or integrated, the power impact part drives the punching teeth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com