Device for controlling constant power of excavator

A power and controller technology, applied in the field of mechatronics, which can solve problems such as power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

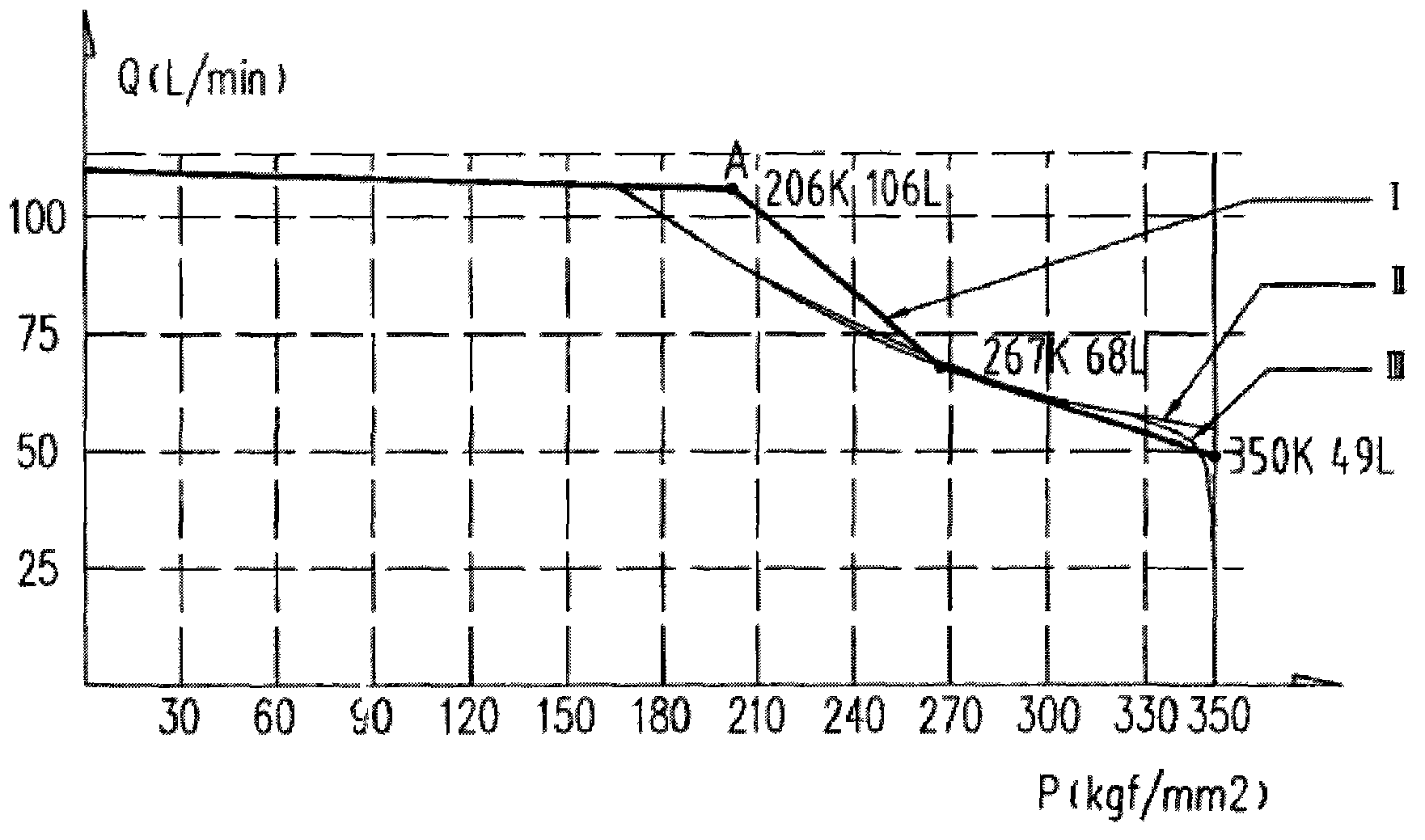

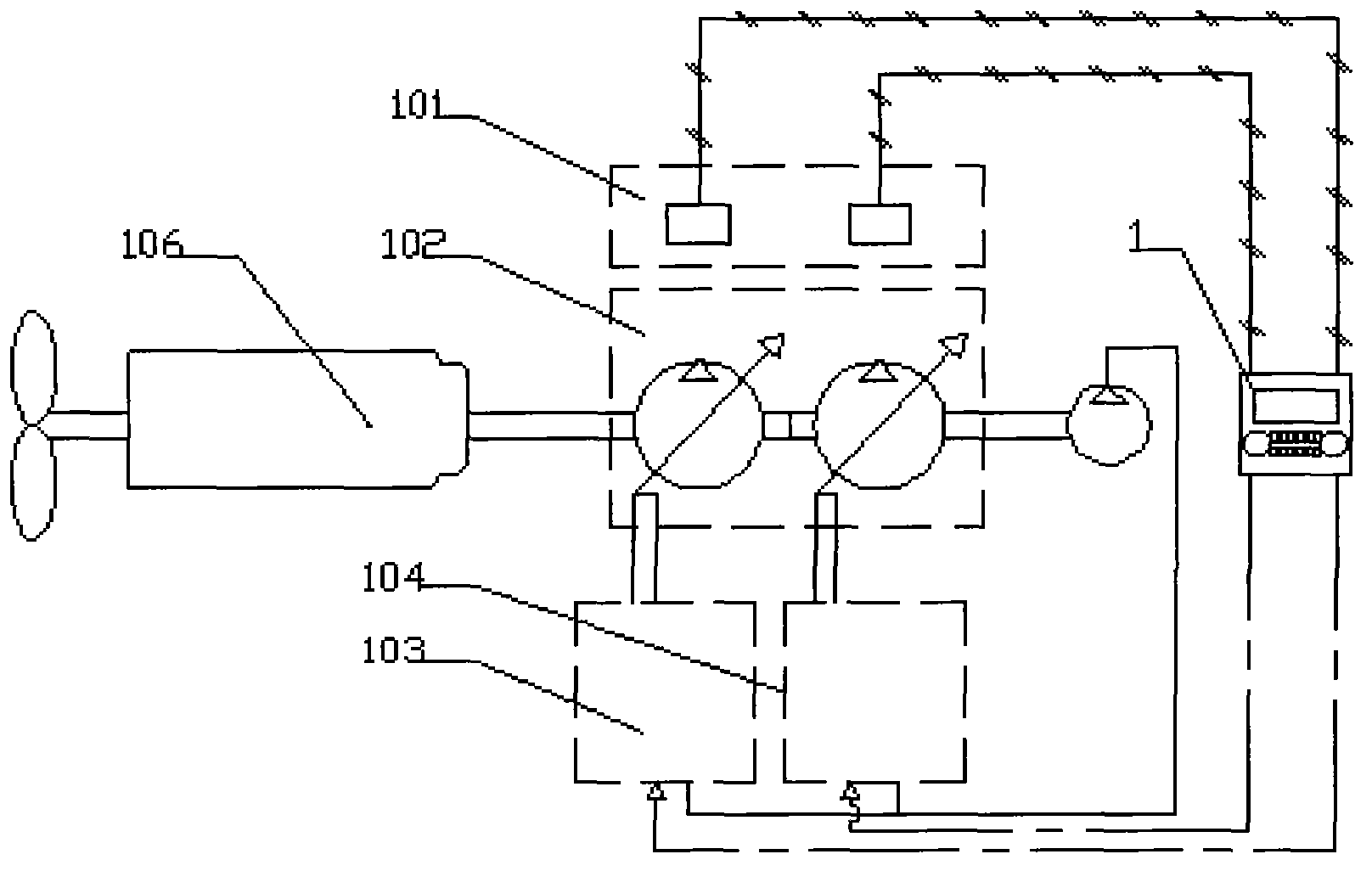

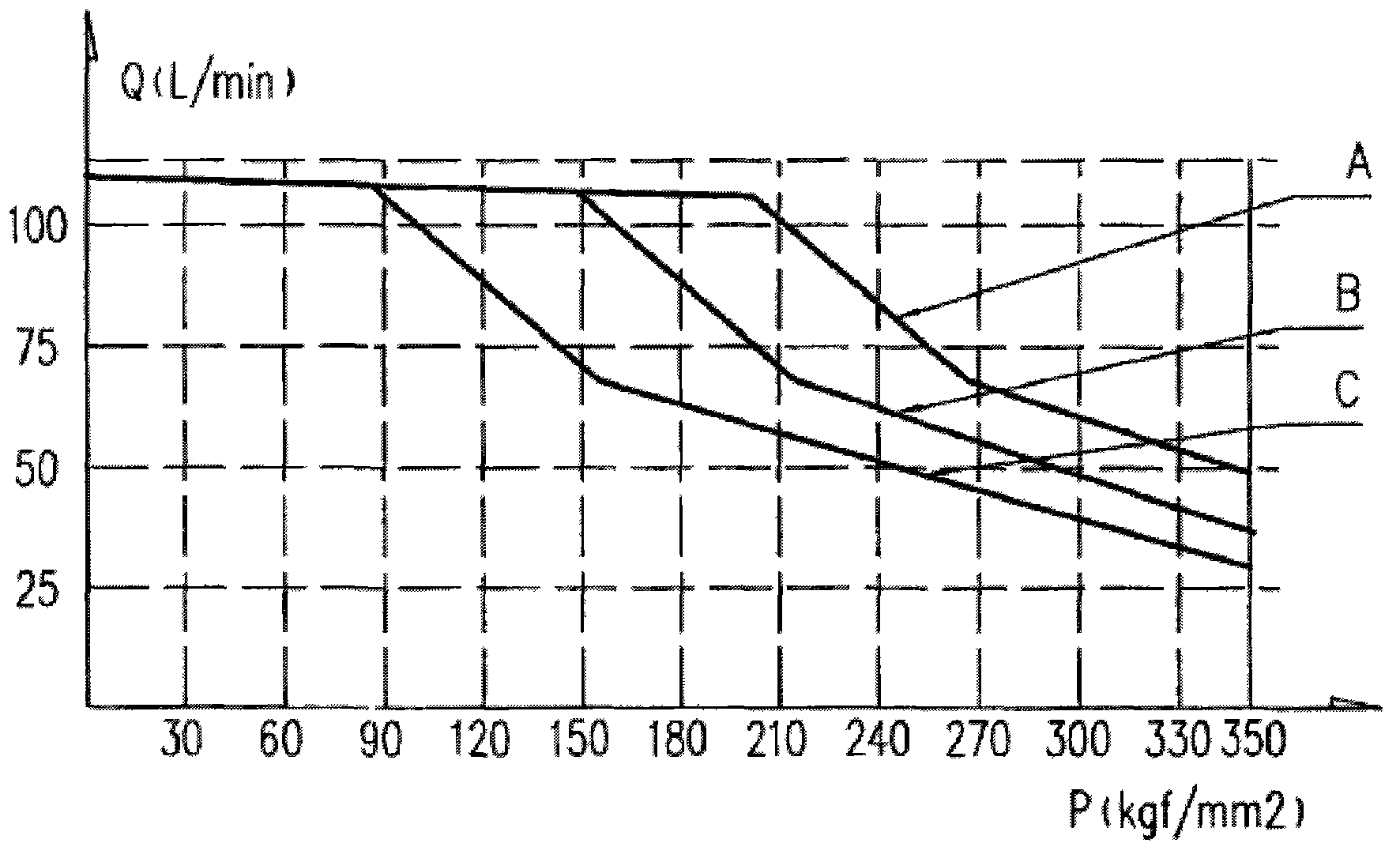

[0064] according to Figure 2-5 , the specific implementation of the preferred embodiment of the present invention is as follows, specifically, a power adjustment system for a plunger type double swash plate variable pump is provided, the system includes a pressure sensor transmitter group 101, a plunger type double A swash plate variable pump unit 102, a first power adjustment module 103, a second power adjustment module 104, a main computer controller 1 and an engine 106. Among them, the measured value of the pressure sensor transmitter group 101 is transmitted to the host computer controller 1, and the host computer controller 1 controls the plunger type double swash plate variable pump group through the first power adjustment module 103 and the second power adjustment module 104. 102 to adjust, it is characterized in that: the main computer controller is a three-dimensional dot-matrix MCU constant power controller composed of single-chip microcomputers, according to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com