Indigo blue oxidation filter cake post-treatment process

A technology of filter cake and indigo, which is applied in the field of production technology of traditional dye indigo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

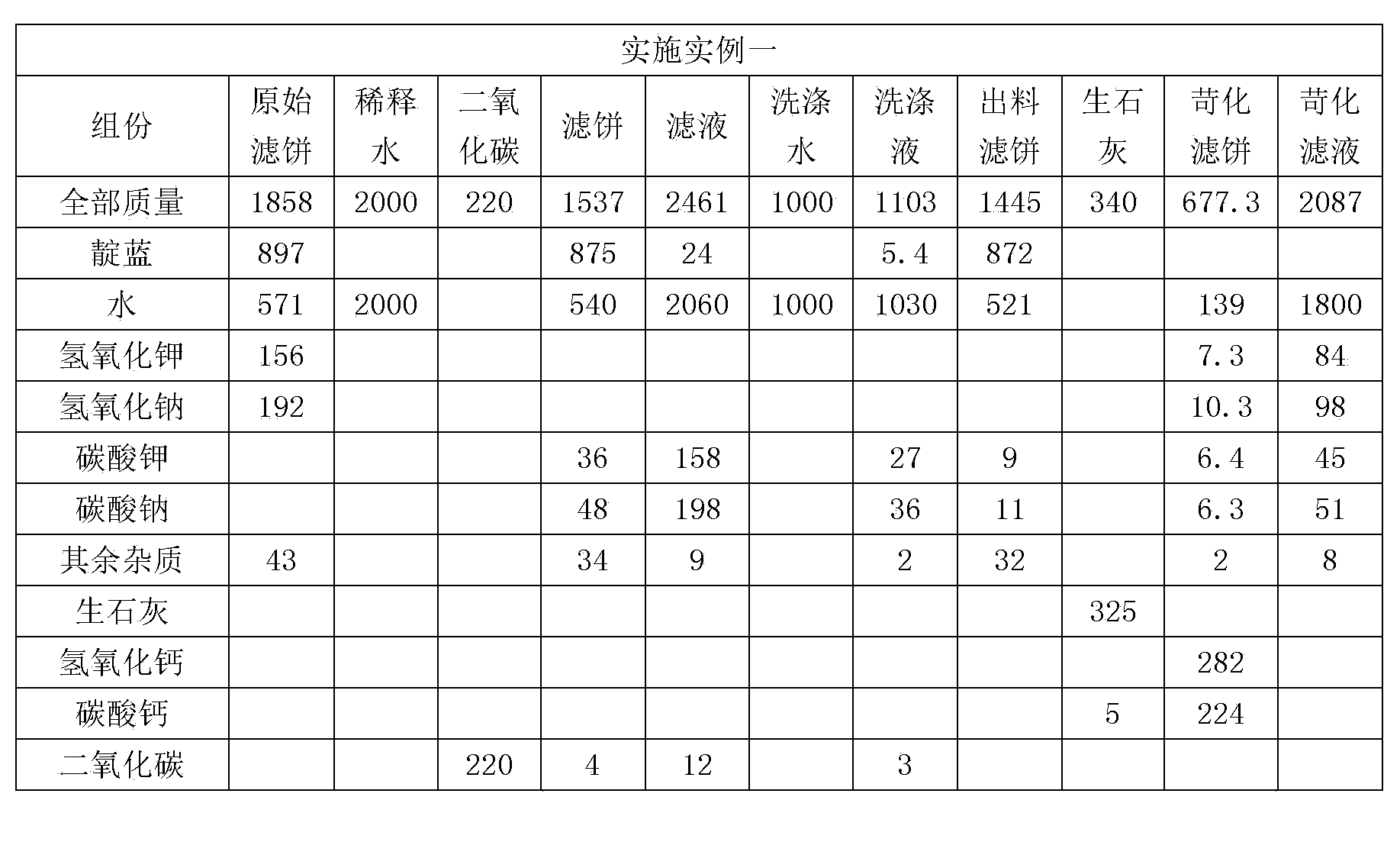

Embodiment 1

[0012] Embodiment 1: Get 1.86 kilograms of indigo oxidation filter cake, add 2000g water to dilute, pass into 220 grams of carbon dioxide in the form of bubbling gradually under stirring state, most of carbon dioxide is absorbed, a small amount of discharge system. Filter the reaction solution again to obtain the neutralized filter cake and the neutralized filtrate, get 1000g of water to wash the neutralized filter cake, and obtain the neutralized washing liquid, and the neutralized washed liquid is prepared to be used as dilution water next time, and the neutralized filter cake after washing is directly Go to the drying and granulation section for processing. Add 340 grams of fine powdered quicklime to the neutralized filtrate, fully stir and react under reflux for 36 hours, and filter after the reaction to obtain causticizing filter cake and causticizing filtrate. The single-pass recovery rate of potassium hydroxide reaches more than 60%. The content of each component is li...

Embodiment 2

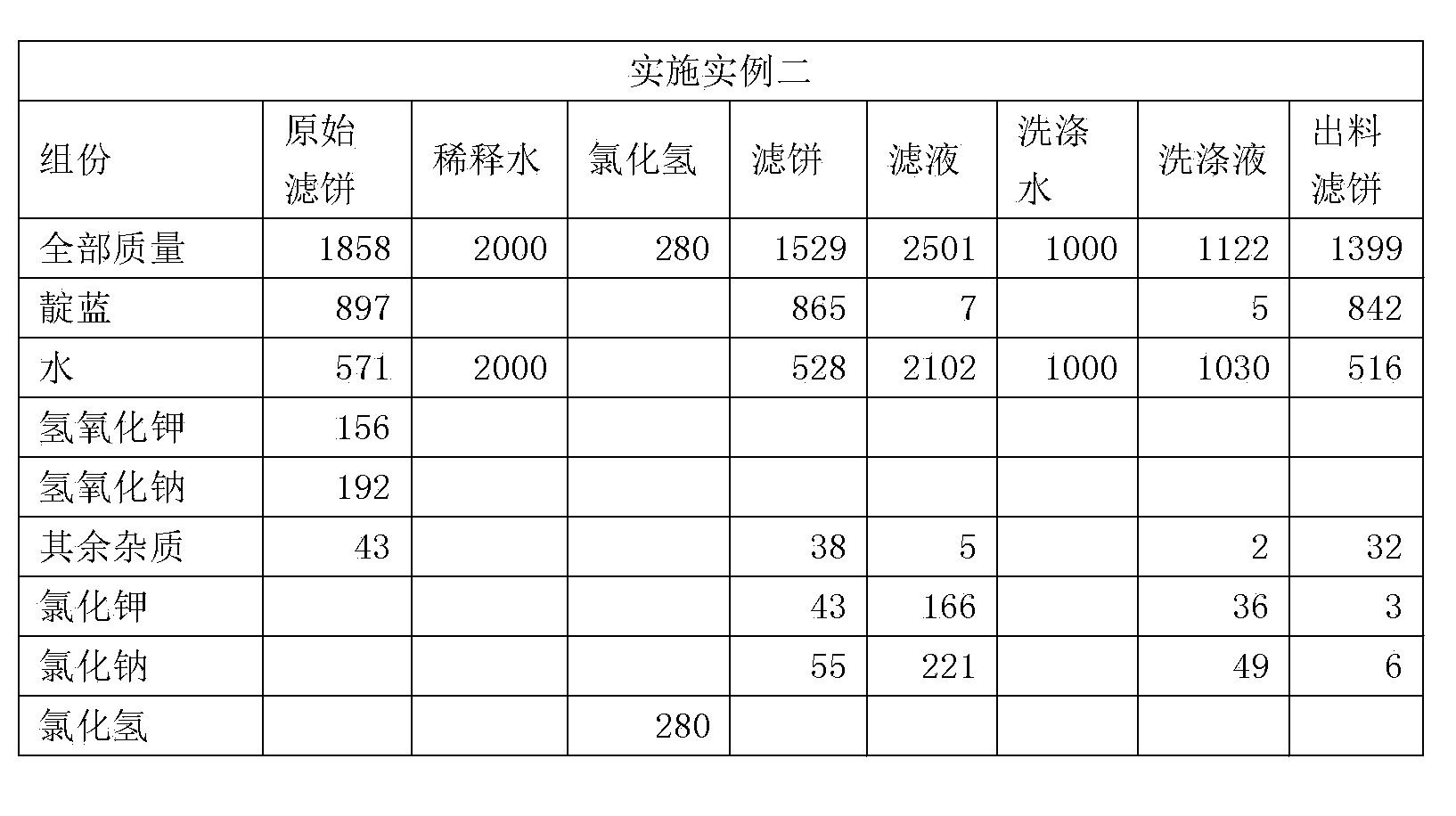

[0014] Embodiment 2: Get 1.86 kilograms of indigo oxidation filter cake, add 2000g water to dilute, pass into 280 grams of hydrogen chloride gradually under stirring state. Filtrate again to obtain a neutralized filter cake and a neutralized filtrate, take 1000 g of water to wash the neutralized filter cake, and obtain a neutralized washing liquid. The content of each component is listed in the table below. The filtrate can be refined and electrolyzed to produce potassium hydroxide, with a single-pass recovery rate of over 80%.

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com