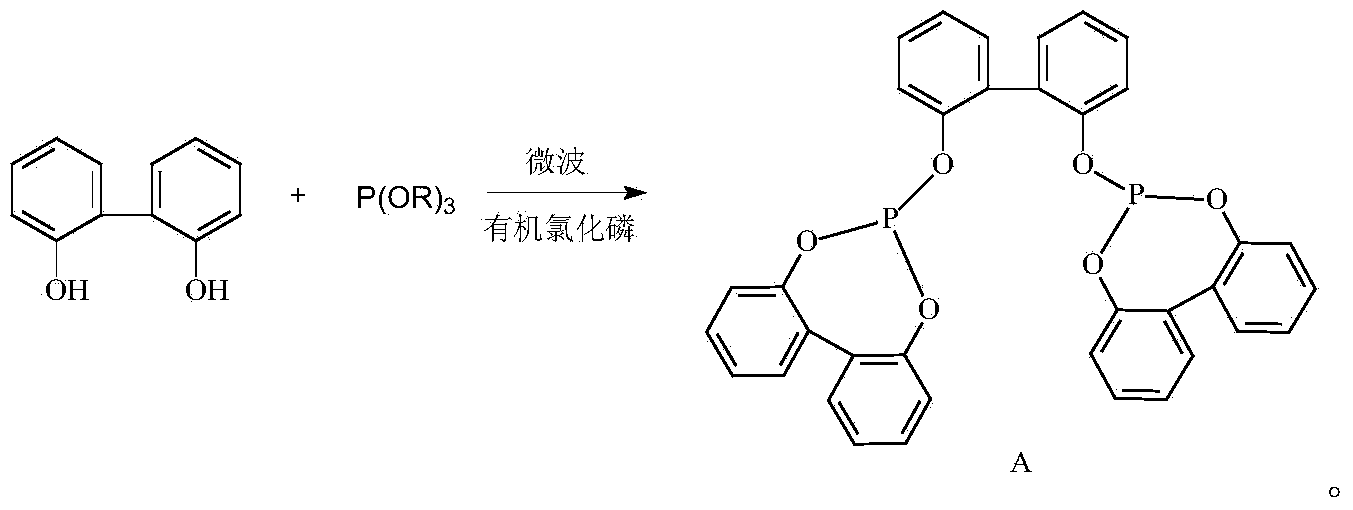

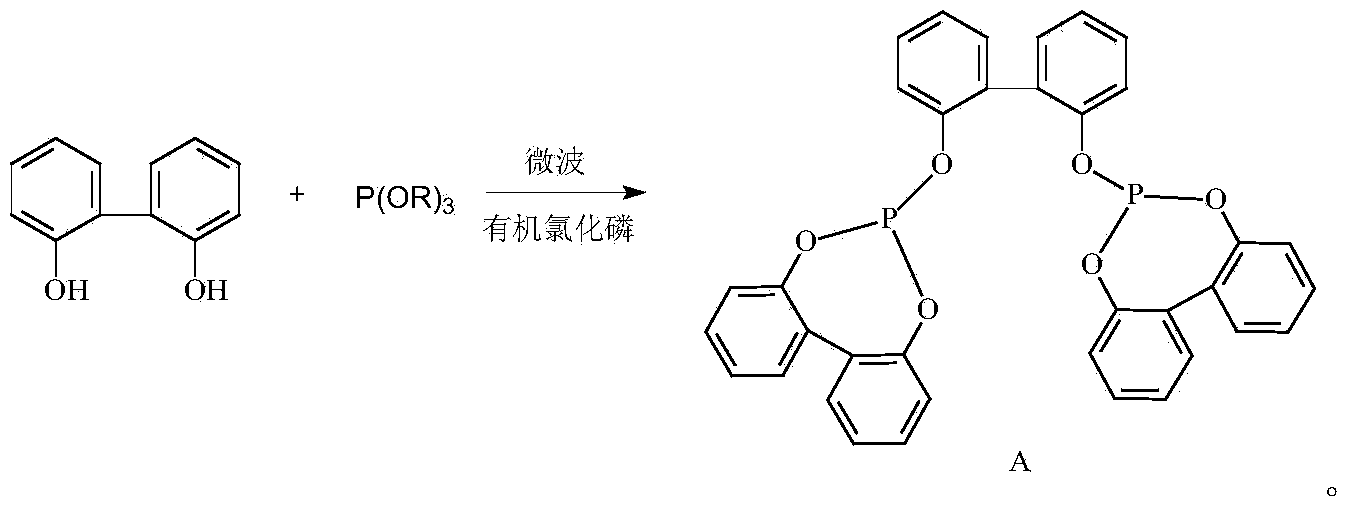

Microwave synthesis method for tri(2,2'-diphenol) biphosphite

A technology of bis-tri- and tri-alkyl phosphite is applied in the field of preparation of bis-phosphite ligands and achieves the effects of environmental friendliness, no pollution, solvent-free operation and simple post-treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put 16.6 grams of triethyl phosphite, 18.6 grams of 2,2'-biphenol and 1.7 grams of diphenyl phosphorus chloride catalyst in a microwave reaction device, mix and stir evenly, and then react under microwave radiation with a power of 200w for 15 Minutes, after the completion of the reaction, the reaction crude product was recrystallized with a mixed solvent of toluene and n-hexane to obtain white crystals, which were verified by H NMR spectrum, phosphorus spectrum and high performance liquid chromatography, and the product was bisphosphite tris(2,2' -biphenol) ester, the yield is 90% (the yield is calculated based on 2,2'-biphenol).

Embodiment 2

[0022] Put 49.8 grams of triethyl phosphite, 18.6 grams of 2,2'-biphenol and 0.7 grams of phenylphosphorus dichloride catalyst in a microwave reaction device, mix and stir evenly, and react under microwave radiation with a power of 200w for 15 Minutes, after the completion of the reaction, recrystallize the crude product with acetonitrile to obtain white crystals, which are verified by H NMR spectrum, phosphorus spectrum and high performance liquid chromatography, and the product is tris(2,2'-biphenol) bisphosphite , the yield is 92% (the yield is calculated based on 2,2'-biphenol).

Embodiment 3

[0024] Put 24.8 grams of trimethyl phosphite, 18.6 grams of 2,2'-biphenol and 4.3 grams of diphenyl phosphorus chloride catalyst in a microwave reaction device, mix and stir evenly, and then react under microwave radiation with a power of 500w for 10 minutes, after the reaction was completed, the crude product of the reaction was recrystallized with a mixed solvent of ethyl acetate and sherwood oil to obtain white crystals, which were verified by proton nuclear magnetic resonance spectrum, phosphorus spectrum and high performance liquid chromatography, and the product was bisphosphite tris(2, 2'-biphenol) ester, the yield is 95% (the yield is calculated based on 2,2'-biphenol).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com