Method for preparing (1R,3S)-3-aminomethyl-2,2-dimethyl cyclopropane methyl alcohol and salts thereof

A technology of dimethylcyclopropanyl and aminomethyl, which is applied in the field of drug synthesis, can solve the problems of severe reduction reaction conditions, influence on industrial applications, and harsh temperature requirements, and achieve short reaction time, low risk, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

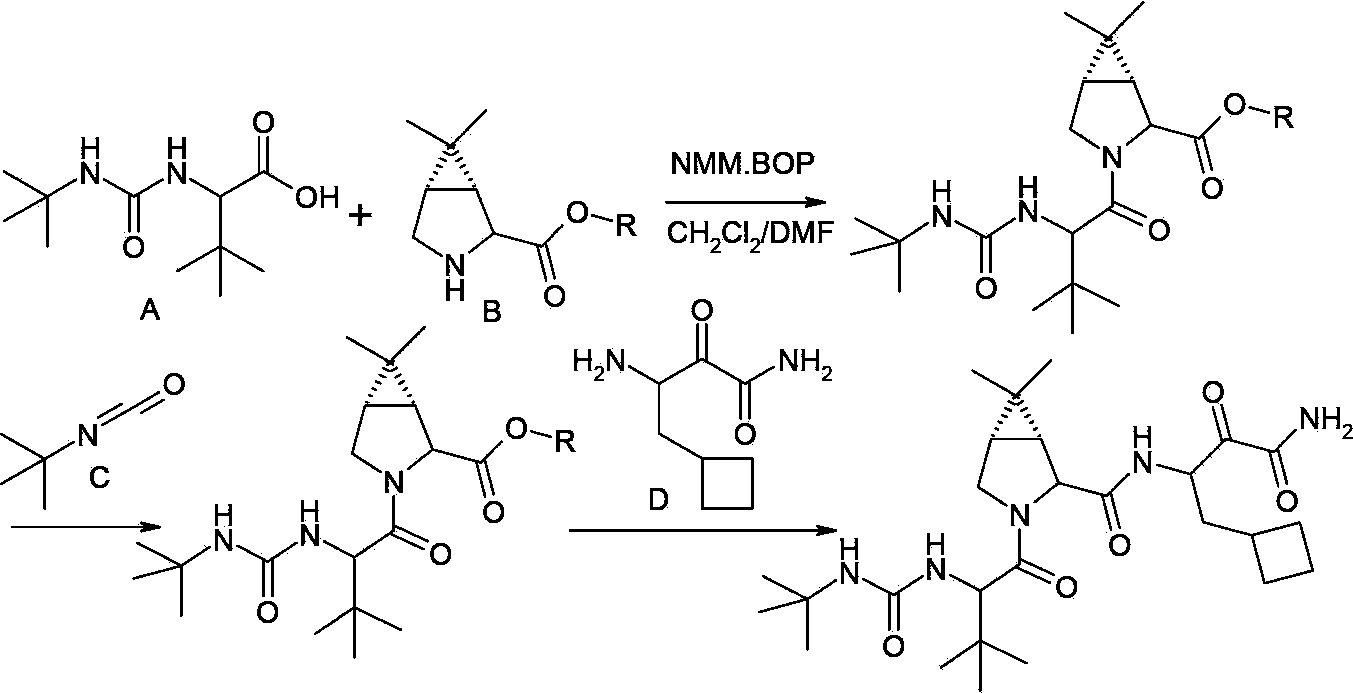

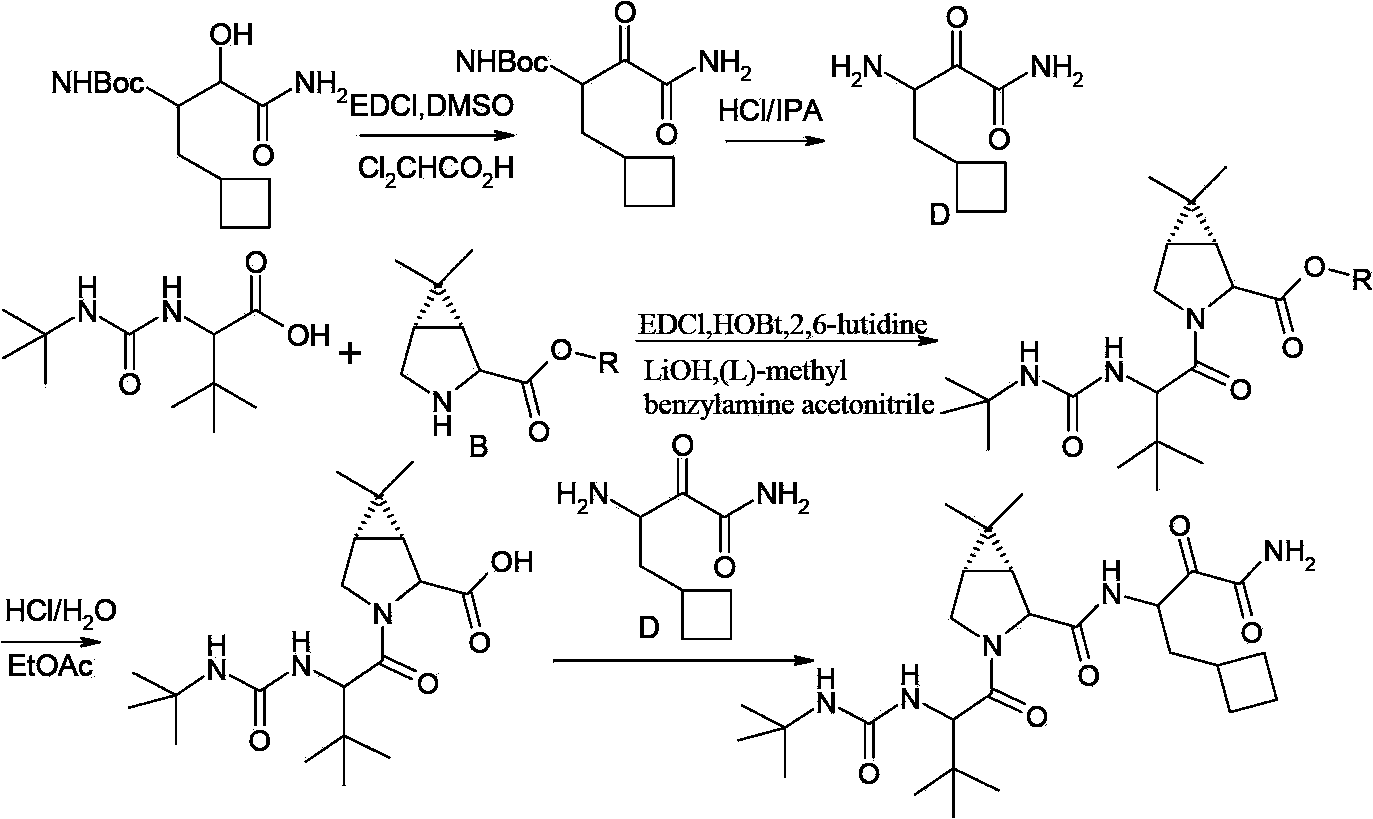

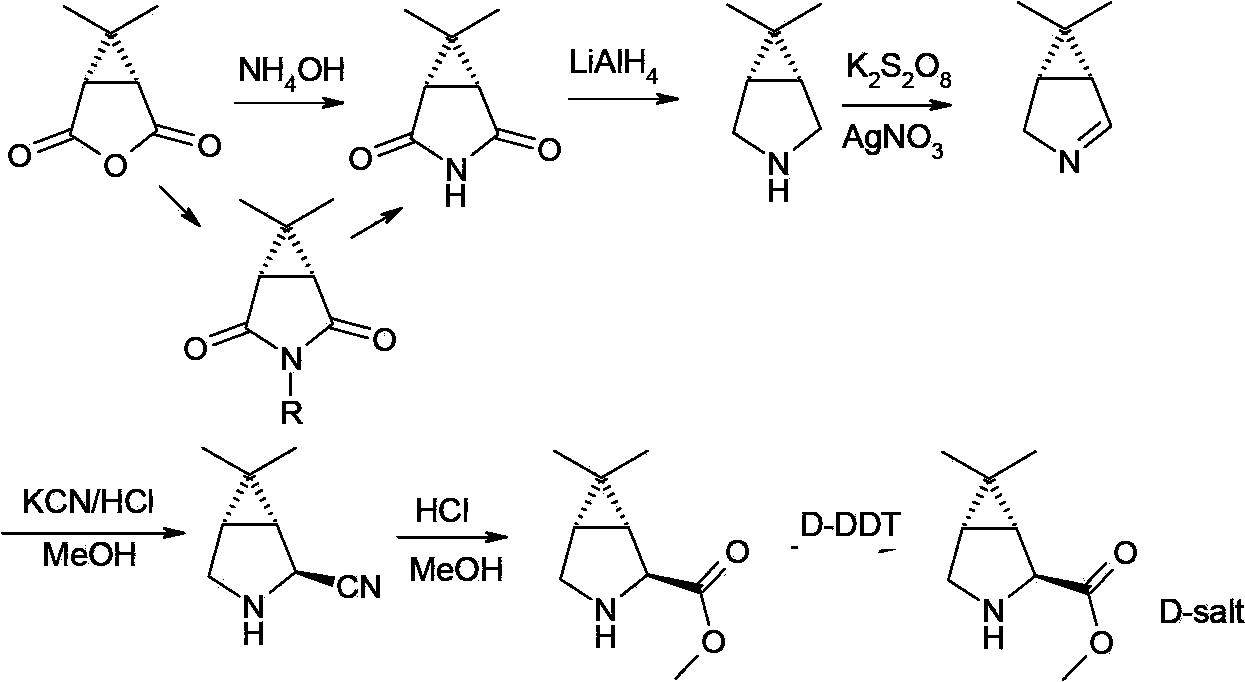

Method used

Image

Examples

Embodiment 1

[0041]

[0042] Under argon atmosphere, add formula I compound (69.3g, 0.35mol, 1.0eq) and 500mL tetrahydrofuran (THF) into 1L reaction bottle, ice bath cooling to 5~10 ℃; Add sodium borohydride (32.0g, 0.82mol , 2.3eq) and iodine (91g, 0.35mol, 1eq); heated to reflux; after reflux for 5-8 hours, cool the reaction solution to 5-10°C, add 100mL methanol to the reaction system to quench the reaction; filter, concentrate methanol in the dry filtrate; add 800mL ethyl acetate to the concentrated residue, and stir at room temperature for 2 to 3 hours; filter and concentrate the ethyl acetate in the dry filtrate to obtain (1R,3S)-3-aminomethyl- Crude 2,2-dimethylcyclopropanylmethanol; add excess benzoic acid to the above crude product at -5-10°C, stir for 2-3 hours to form a salt; filter, wash, and vacuum-dry at 40°C for 5- After 8 hours, 80.3 g of benzoate of (1R,3S)-3-aminomethyl-2,2-dimethylcyclopropanylmethanol was obtained (91.2% molar yield).

[0043] The obtained hydrogen ...

Embodiment 2

[0045] Under argon atmosphere, add formula I compound (69.3g, 0.35mol, 1.0eq) and 500mL dichloromethane into 1L reaction bottle, ice bath cooling to 5 ~ 10 ℃; add lithium borohydride (15.2g, 0.45mol, 1.3eq) and iodine (91g, 0.35mol, 1eq); heat to reflux; after reflux for 5-8 hours, cool the reaction solution to 5-10°C, add 100mL methanol to the reaction system to quench the reaction; filter and concentrate to dryness Methanol in the filtrate; add 800mL ethyl acetate to the concentrated residue, stir at room temperature for 3 to 5 hours; filter, concentrate and dry the ethyl acetate in the filtrate to obtain (1R,3S)-3-aminomethyl-2 , crude 2-dimethylcyclopropanylmethanol; add excess benzoic acid to the above crude product at -5-10°C, stir for 2-3 hours to form a salt; filter, wash, and vacuum-dry at 40°C for 5-8 hours, 77.3 g of benzoate of (1R,3S)-3-aminomethyl-2,2-dimethylcyclopropanylmethanol was obtained (molar yield: 87.2%).

[0046] The hydrogen spectrum data of the obtain...

Embodiment 3

[0048] Under argon atmosphere, add formula I compound (60g, 0.30mol, 1.0eq) and 500mL dioxane to 1L reaction bottle, cool to 5~10℃ in ice bath; add potassium borohydride (32.8g, 0.82mol, 2.0eq) and iodine (78g, 0.30mol, 1eq); heat to reflux; after reflux for 5-8 hours, cool the reaction solution to 5-10°C, add 80mL methanol to the reaction system to quench the reaction; filter, concentrate to dryness Methanol in the filtrate; add 500mL ethyl acetate to the concentrated residue, stir at room temperature for 3 to 5 hours; filter, concentrate and dry the ethyl acetate in the filtrate to obtain (1R,3S)-3-aminomethyl-2 , crude 2-dimethylcyclopropanylmethanol; add excess benzoic acid to the above crude product at -5-10°C, stir for 2-3 hours to form a salt; filter, wash, and vacuum-dry at 40°C for 5-6 hours, 63.5 g of benzoate of (1R,3S)-3-aminomethyl-2,2-dimethylcyclopropanylmethanol was obtained (molar yield: 83.0%).

[0049] The hydrogen spectrum data of the obtained benzoate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com