Sewage sludge and kitchen waste treatment device and treatment method

A technology for kitchen waste and sewage sludge, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., to improve volume utilization efficiency and promote nutritional balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

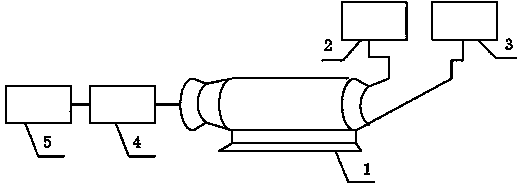

[0047] Such as figure 1 As shown, a treatment device for sewage sludge and kitchen waste includes a homogeneous slurry treatment reactor 1, a sewage sludge pretreatment device 2 and a kitchen waste pretreatment device 3. The homogeneous slurry treatment reaction The device 1 is in communication with the sewage sludge pretreatment device 2, and the homogeneous slurry treatment reactor 1 is in communication with the food waste pretreatment device 3.

[0048] Further, in order to complete the two-phase anaerobic co-digestion treatment of sewage sludge and food waste, the treatment device for sewage sludge and food waste further includes an acid-producing phase reactor 4 and a methanogenic phase reactor 5. The homogeneous slurry treatment reactor 1 is in communication with the acid-producing phase reactor 4, the acid-producing phase reactor 4 is in communication with the methanogenic phase reactor 5, and the acid-producing phase reactor 4 includes acid-producing stirring And an acid...

Embodiment 2

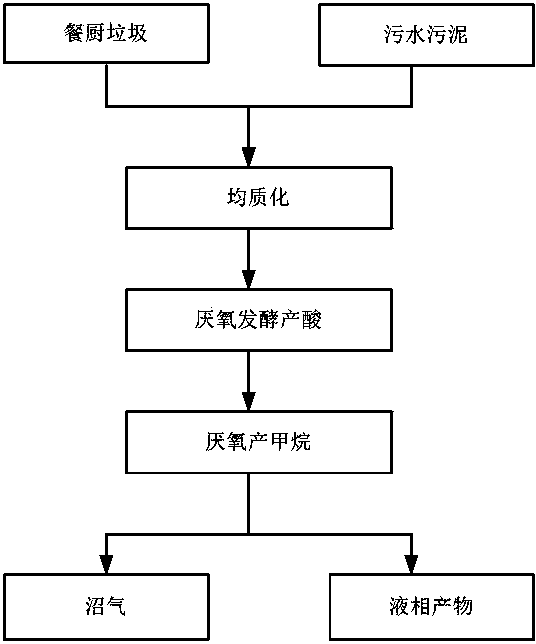

[0052] Combine below figure 1 with figure 2 , A detailed description of the treatment method of sewage sludge and kitchen waste according to an embodiment of the present invention.

[0053] Such as figure 2 As shown, the processing method of sewage sludge and food waste in an embodiment of the present invention includes the following steps:

[0054] Step 1: Use the food waste pretreatment device 3 to sort the food waste, remove the large-size inorganic matter and refractory organic matter, crush the food waste with the pulverizer, and adjust the food waste The moisture content of garbage;

[0055] Specifically, food waste can be taken from canteens, homes, hotels or restaurants. The food wastes are sorted to remove large-size inorganic matter and refractory organic matter, such as bones, toothpicks, napkins, etc., and then The remaining food waste is crushed with a grinder, and the particle size after crushing is 1 mm ~ 3mm. The moisture content of the food waste is adjusted to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com