Optical fiber winding machine provided with wire pressing wheel

A technology with a wire crimping and wire take-up machine, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve problems such as fiber slack and damage, and achieve the effect of increasing the amount of wire taking-up and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in further detail, but structure of the present invention is not limited to following embodiment:

[0018] 【Example】

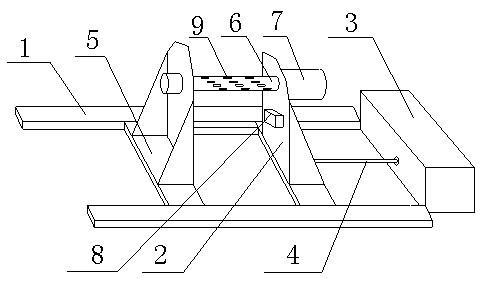

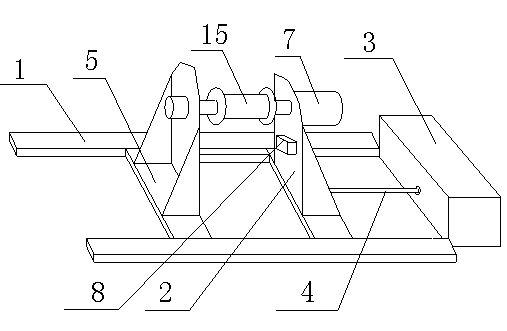

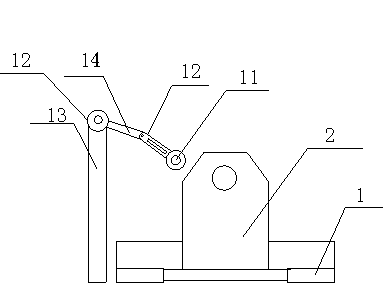

[0019] Such as figure 1 , figure 2 , image 3 As shown, the optical fiber take-up machine provided with crimping wheels includes a track 1, a trolley 2, a traction device 3 and a crimping device 10, the trolley 2 is slidably arranged on the track 1, and is passed through a stretching rod 4 Connect the traction device 3, the pulley 2 includes a base 5 and a rotating shaft 6 installed on the base 5, the rotating shaft 6 is driven to rotate by a rotating motor 7 installed on the base 5, the crimping device 10 includes a crimping roller 11, a crimping Arm 12 and pillar 13, described crimping arm 12 is rotatably installed on the pillar 13, and crimping roller 11 is installed on crimping arm 12 ends.

[0020] Further, the crimping arm 12 includes two sections of straight arms 14 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com