Method for preparing small-size nano-silver with chitosan as reducing agent

A technology of chitosan and small size, which is applied in the field of synthesis of metal nanoparticles to achieve the effect of stable physical and chemical properties, good monodispersity and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A kind of preparation method of the small size nano-silver taking chitosan as reducing agent of the present invention, the steps are as follows:

[0019] Step 1, dissolving chitosan with Mr=60000~120000 in 1% acetic acid solution by volume ratio, dissolving overnight to obtain a chitosan solution with a concentration of 2~6mg / ml;

[0020] Step 2, place the chitosan solution of Mr=60000~120000 newly configured in step 1 in the flask;

[0021] Step 3. Under continuous stirring, mix the newly prepared AgNO with a concentration of 20-60mM 3 The solution was added dropwise into the above-mentioned flask containing the chitosan solution, in which AgNO 3 The volume ratio of the solution to the chitosan solution is 0.2-0.4; then a sodium citrate solution with a concentration of 40 mM is added to the container, wherein the volume ratio of the sodium citrate solution to the chitosan solution is 0.01-0.04;

[0022] Step 4: React in a water bath at 60° C. to 95° C. for 2 hours to...

Embodiment 1

[0025] Dissolve 1.5 g of chitosan with Mr=60000-120000 in an appropriate amount of 1% acetic acid solution by volume, and dissolve overnight so that the concentration of the chitosan solution is 6 mg / ml.

[0026] Add 20ml of chitosan solution with Mr=60000~120000 newly configured and place in the flask.

[0027] Under continuous stirring, 8ml of freshly prepared 60mM AgNO 3 The solution was added dropwise to the flask, followed by the dropwise addition of 0.8 ml of 40 mM sodium citrate solution. React in a water bath at 95°C for 8 hours to obtain nano-silver sol.

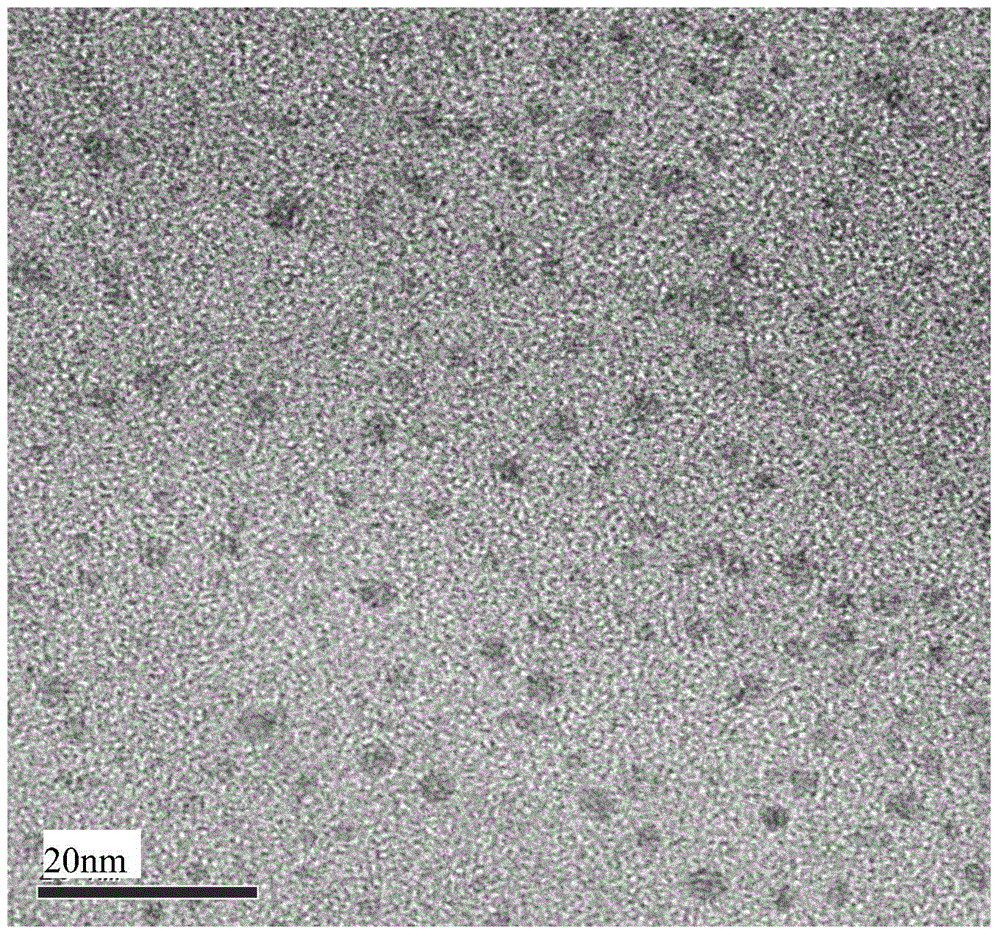

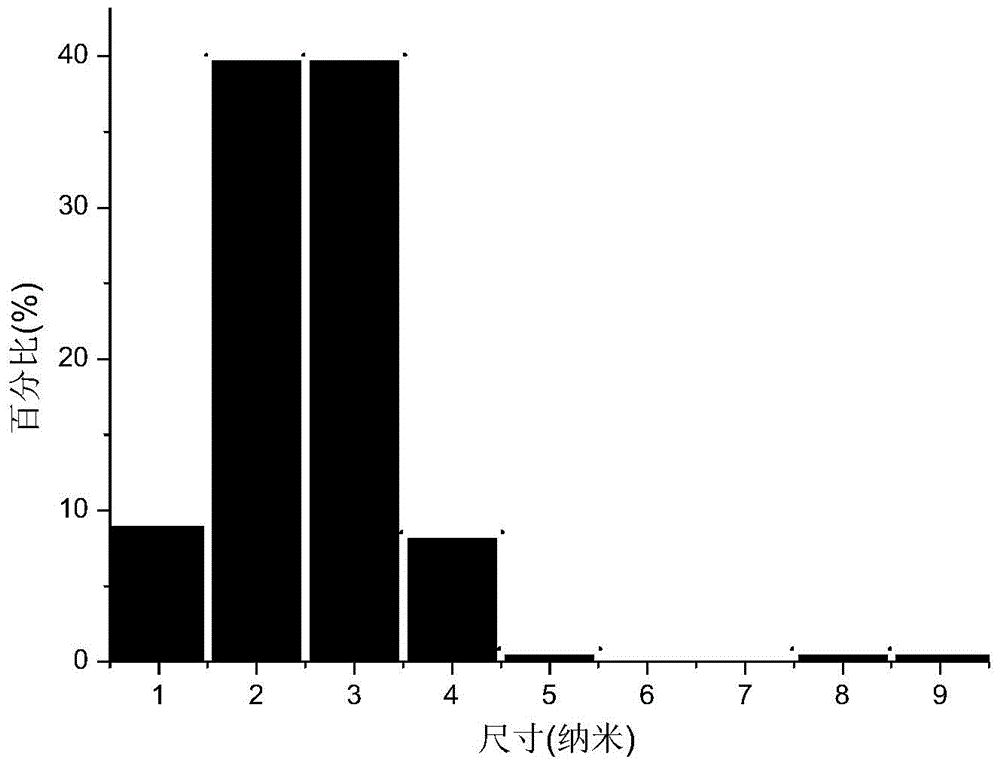

[0028] Picture 1-1 The TEM picture of the silver sol that embodiment 1 obtains is shown, Figure 1-2 It is the particle size distribution figure of silver nanoparticles in the product of Example 1.

Embodiment 2

[0030] Dissolve 1.0g of chitosan with Mr=60000~120000 in an appropriate volume ratio of 1% acetic acid solution, and dissolve overnight. The concentration of the chitosan solution was 4 mg / ml.

[0031] Add 40ml of newly configured Mr=60000~120000 chitosan solution to the flask, and place it in a water bath at 80°C.

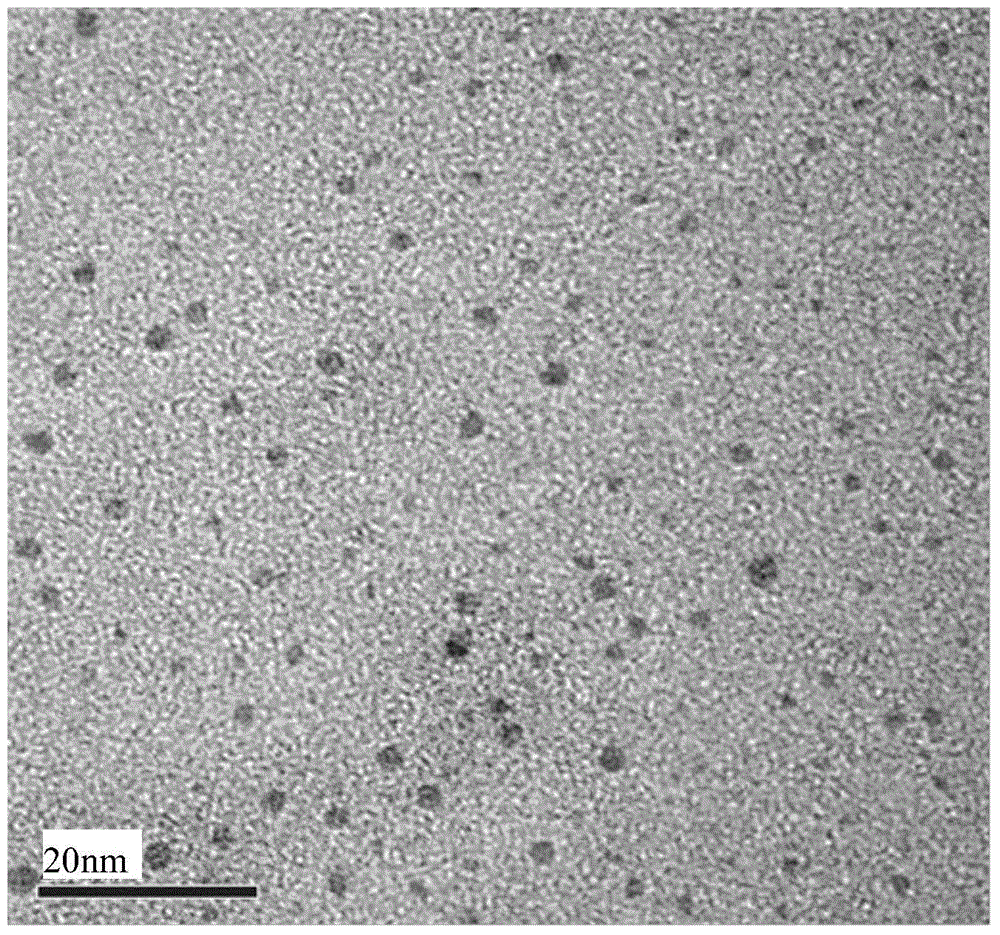

[0032] Under continuous stirring, 8ml of freshly prepared 40mM AgNO 3 The solution was added dropwise to the above flask, followed by the dropwise addition of 0.8 ml of 40 mM sodium citrate solution. React in a water bath at 80°C for 5 hours to obtain nano-silver sol. Figure 2-1 The TEM picture of the silver sol that embodiment 2 obtains is shown, Figure 2-2 It is the particle size distribution figure of silver nanoparticles in the product of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com