Equipment and method for collecting and pretreating kitchen waste

A kitchen waste and pretreatment technology, applied in the field of kitchen waste collection and pretreatment, can solve the problems of reducing the economic benefit of the treatment plant, rot and deteriorate, increasing the difficulty of treatment, etc., achieving good social and economic benefits, extending the shelf life, The effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

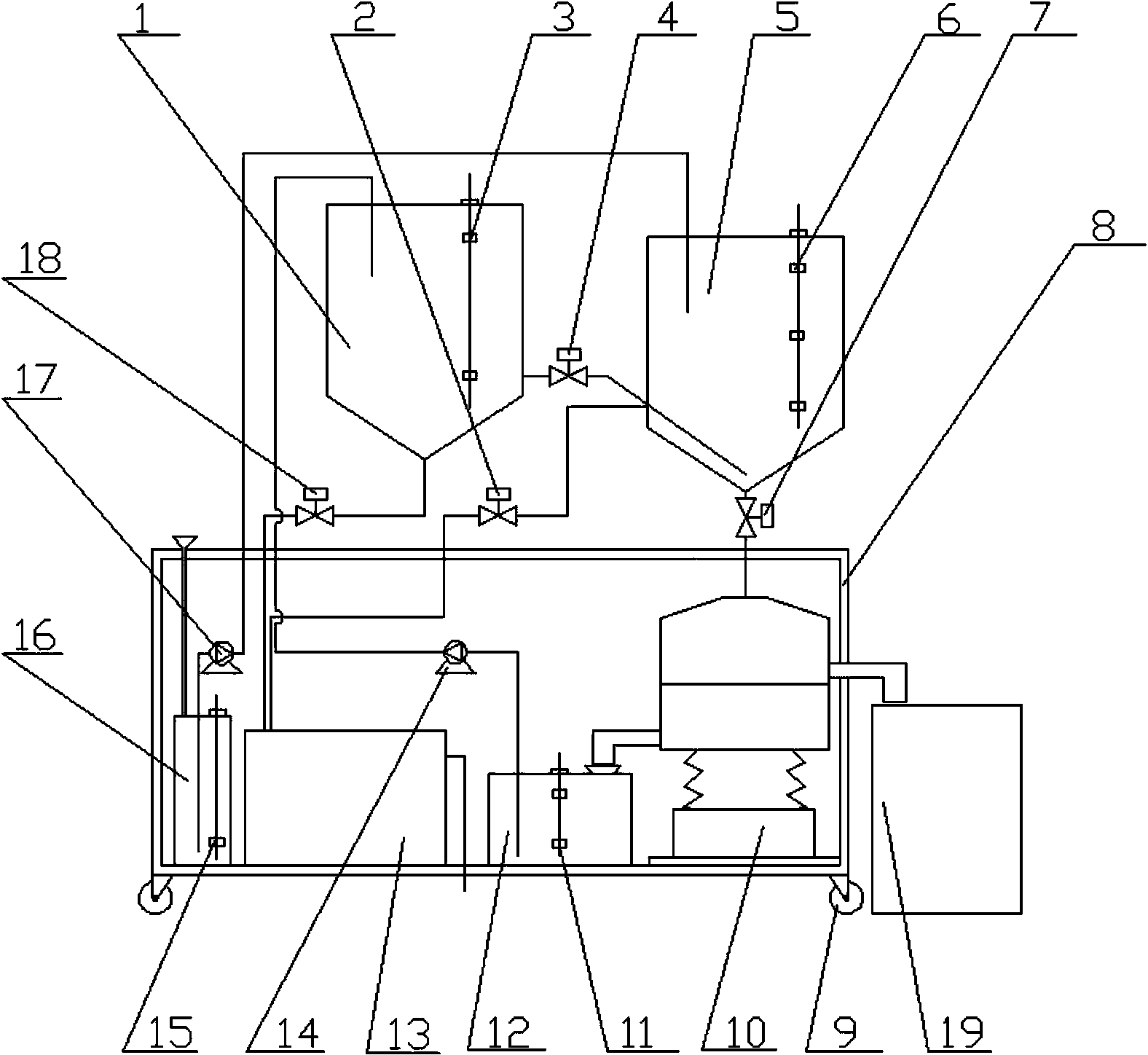

[0045] Such as figure 1 As shown, a kind of food waste collection and pretreatment equipment comprises a frame 8, a food waste solids airtight storage tank 19, and a material liquid temporary storage tank 16 is installed on the said frame 8, and the material liquid is left to settle and store liquid Tank 5, antibacterial agent feed liquid storage tank 1, vibrating screen 10 installed below the feed liquid static settlement liquid storage tank 5, antibacterial agent feed liquid turnover liquid storage tank 12 and oil-water separator 13, the machine The above-mentioned devices provided on the frame 8 communicate with each other through pipelines, automatically controlled delivery pumps or automatic control valves arranged on the pipelines. Specifically, the feed-liquid temporary storage tank 16 communicates with the feed-liquid static settlement liquid storage tank 5 through pipelines and feed-liquid delivery pump 17, and the feed-liquid static settlement liquid storage tank 5 i...

Embodiment 2

[0070] A method for collecting and pretreating food waste, referring to Example 1, the difference is that the standing time in step b standing for solid-liquid separation is 180 minutes, and in step d, 15 liters of plant milk with a pH value of 4 is used Soak in the bacillus fermentation culture solution for 2 minutes, and in step e, use a centrifuge to separate the solid-liquid from the food waste sediment soaked in the Lactobacillus plantarum bacteriostatic agent feed solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com