One-sided packaged U-shaped hollow fiber membrane element and component

A fiber membrane and hollow technology, applied in the field of membrane separation equipment, can solve the problems of membrane elements such as weak universal design function, inability to combine immersion, internal pressure function, and complicated sealing design, so as to reduce the risk of leakage and improve the membrane quality. The effect of surface utilization and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

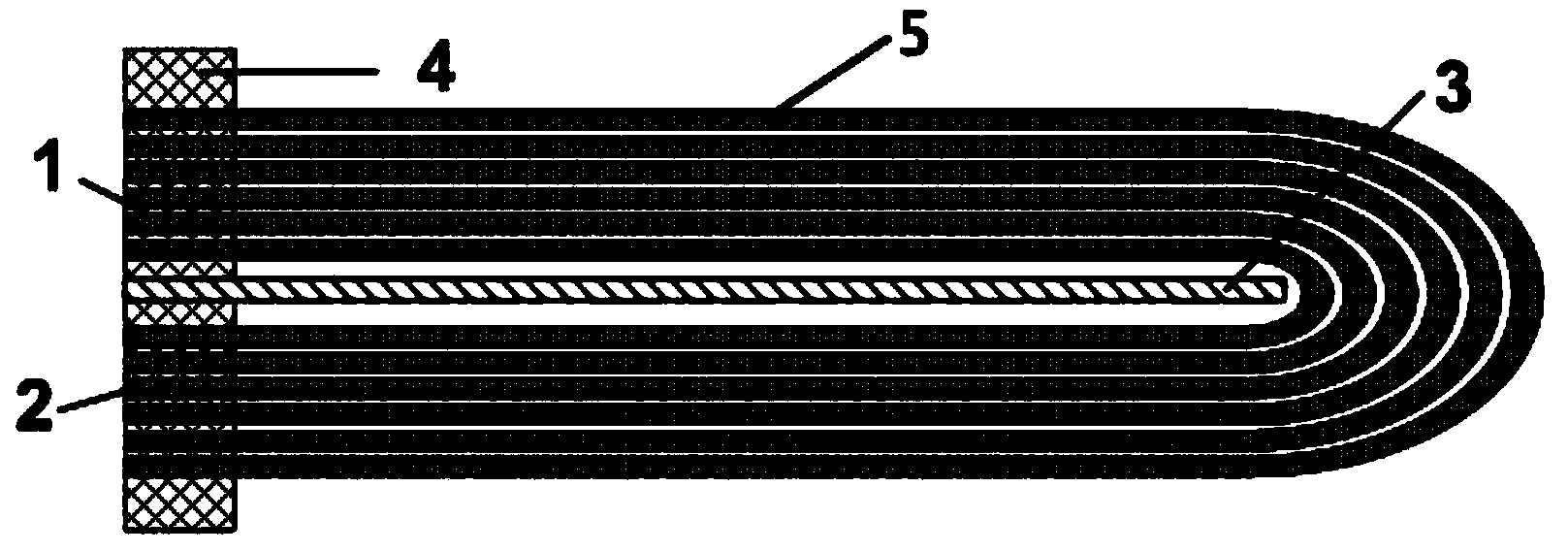

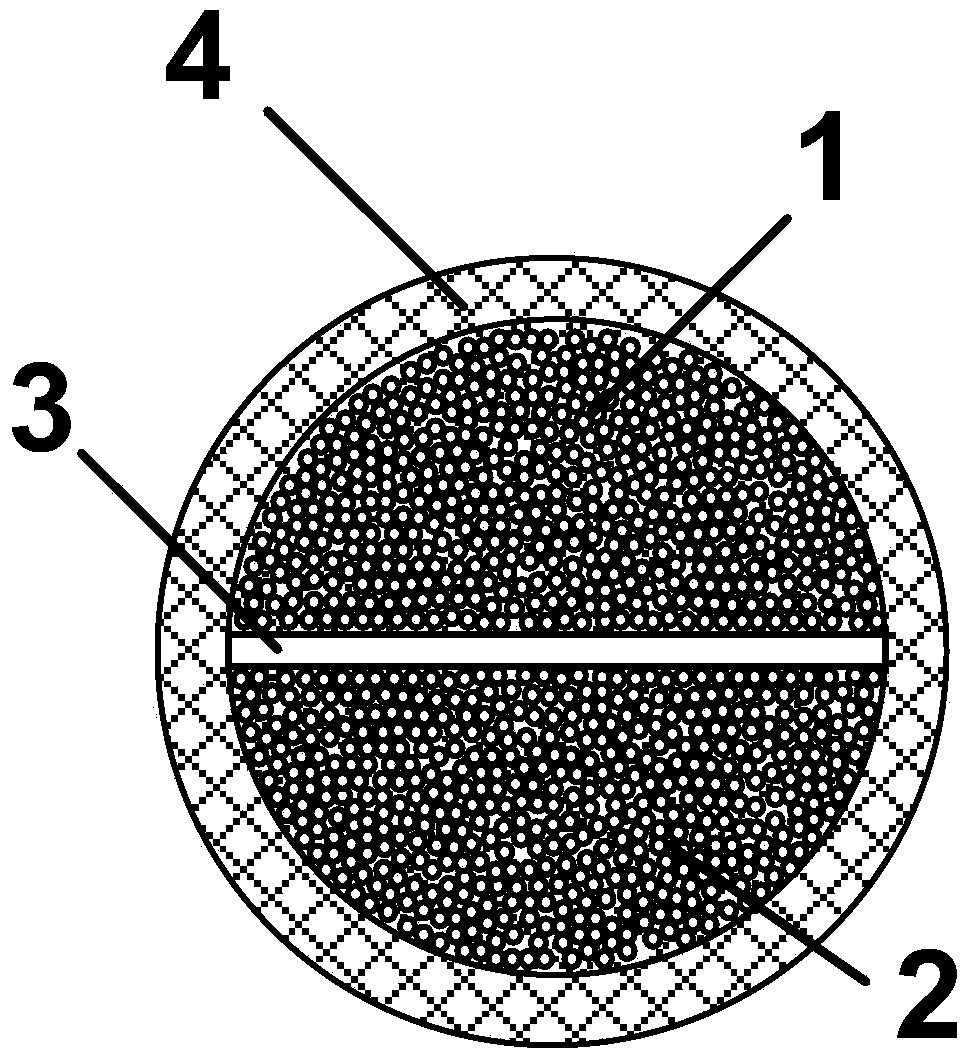

[0037] Example 1 One-sided encapsulation of U-shaped hollow fiber membrane elements

[0038] Such as figure 1 and figure 2As shown, a U-shaped hollow fiber membrane element encapsulated on one side includes a hollow fiber membrane bundle 5, a central diaphragm and a sealing head 4, and the hollow fiber membrane bundle 5 is bent 180 degrees along the central diaphragm to form a U Type hollow fiber membrane bundles, the hollow fiber membrane bundles 5 before and after bending are separated by a central diaphragm, and the two ends of each membrane filament are located on both sides of the central diaphragm. The head end 1, the tail end 2 of the hollow fiber membrane bundle 5 and one end or the proximal end of the central diaphragm are casted and solidified to form the sealing head 4, and the sealing head 4 is opened to form a hollow fiber membrane element. The sealing material used for the sealing head may be epoxy resin, phenolic resin, acrylic sealant, polyurethane sealant, ...

Embodiment 2

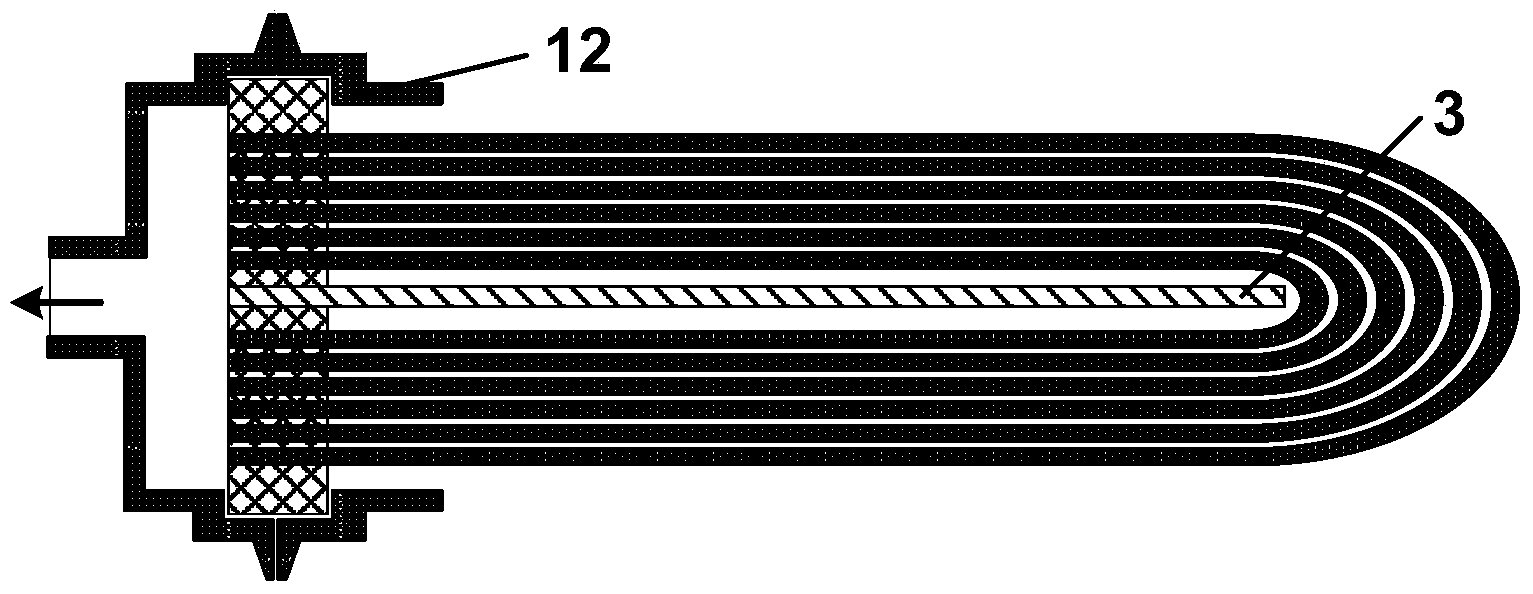

[0041] Example 2 Submerged External Pressure Hollow Fiber Membrane Module

[0042] Such as image 3 As shown, a submerged external pressure hollow fiber membrane module, the hollow fiber membrane module includes an upper end cover 8, a lower end cover 12 and the hollow fiber membrane element, and one end of the upper end cover 8 and the lower end cover 12 Both are provided with openings, and the other ends of the upper end cover 8 and the lower end cover 12 are both sealed and connected with the sealing head 4 , and the lower end cover 12 is tightly connected with the upper end cover 8 . The central transverse partition is a solid partition 3, and the solid partition 3 is sealed in the sealing head 4, and the sealing head 4 is cut flat to expose the hole in the membrane. The hollow fiber membrane element is directly immersed in the feed liquid, the permeate permeates through the membrane surface and collects in the upper end cover 8 and absorbs the produced water, and the pro...

Embodiment 3

[0043] The hollow fiber membrane module of the present invention has a length of 0.5m, a diameter of 4 inches, an effective length of the membrane of 0.8m, and a PVDF outer pressure membrane with an outer diameter of 1mm and an inner diameter of 0.6mm, and a membrane area of 2m 2 , The filling rate is 90%. Example 3 Aeration Submerged External Pressure Hollow Fiber Membrane Module

[0044] Such as Figure 4 As shown, the structure of the aeration submerged external pressure hollow fiber membrane module in this embodiment is basically the same as that in Embodiment 2, the only difference is that the central diaphragm is an aeration plate 13, and the aeration plate 13 passes through The transparent sealing layer extends to the outside of the open end of the upper end cover 8, and the shown aeration plate 13 is a hollow porous plate. The membrane filaments and the aeration tube are directly immersed in the feed liquid, the aeration plate 13 is fed with air or ozone, and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com