Two-stage double-circulation spray packing composite absorption tower

A technology of spray packing and double circulation, which is applied in the field of reactors, can solve problems such as no industrialization reports, and achieve the effects of saving investment and operating costs, simple and reliable process, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

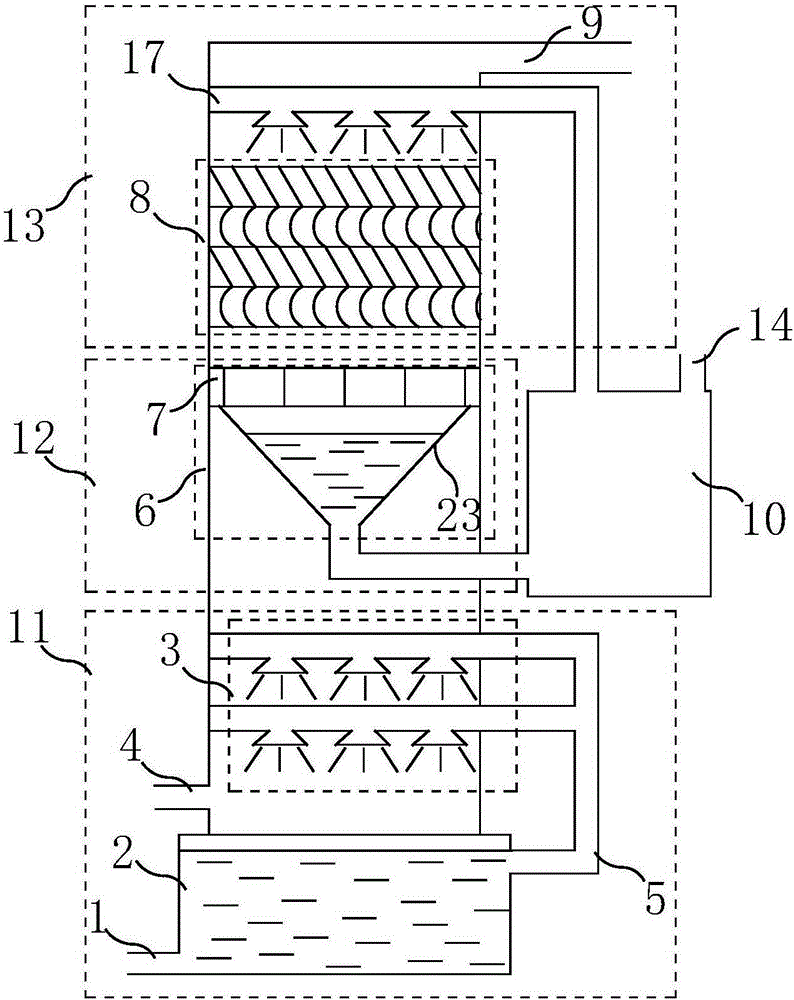

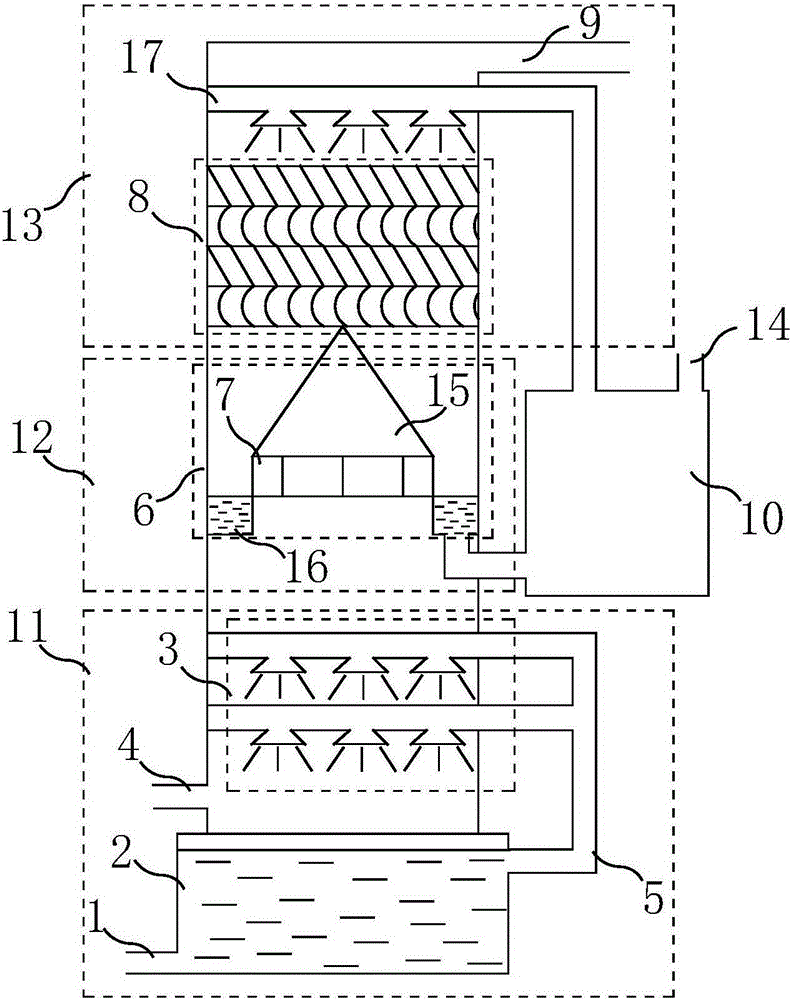

[0031] Embodiment 1, Figure 1 ~ Figure 4 A two-stage double-circulation spray packing composite absorption tower is given; it includes a spray section 11, a transition section 12 and a packing section 13 arranged in sequence from bottom to top; the spray section 11 is provided with a flue gas inlet 4 and a flue gas The purification device I; the transition section 12 is provided with a collector 6; the packing section 13 is provided with a flue gas outlet 9 and a flue gas purification device II.

[0032] The flue gas purification device I includes a spray layer 3, an absorbent circulation device 5 and an oxidation pool 2; the upper and lower layers are set between the spray layer 3 and the oxidation pool 2, and the injection port of the spray layer 3 is downward, and the spray layer 3 and the oxidation pool 2 are connected through an absorbent circulation device 5, and the substances in the oxidation pool 2 are circulated to the spray layer 3 for spraying through the absorben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com