Light guide plate, planar light emitting device, liquid crystal display device, liquid crystal display terminal equipment and manufacturing method of light guide plate

A technology of light guide plate and light plane, applied in the field of light guide plate, can solve the problems of large loss of light energy, destroy the principle of total reflection of the light guide plate, unable to transmit light, etc., and achieve the effect of good light efficiency effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

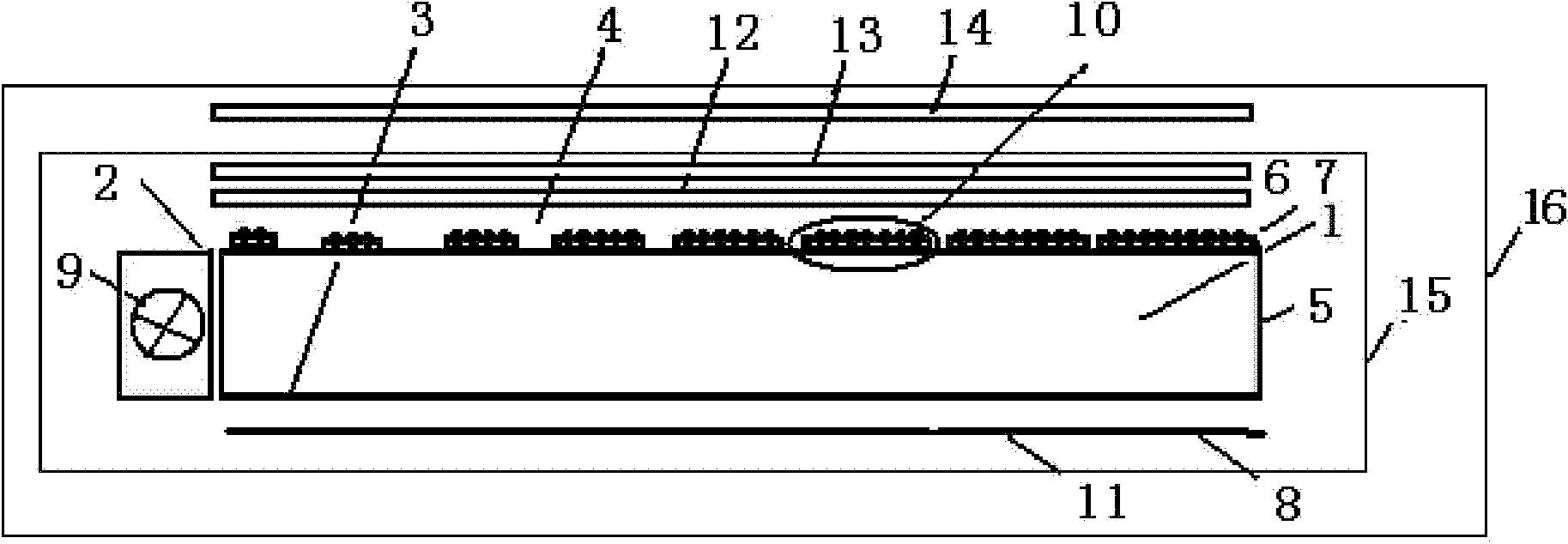

[0086] Embodiment 1: refer to Figure 22 , 5 , 12, 14, 15, 16, 20, 1, 9, 10, 21, 27, 32-inch LCD TV light guide plate and its LCD TV

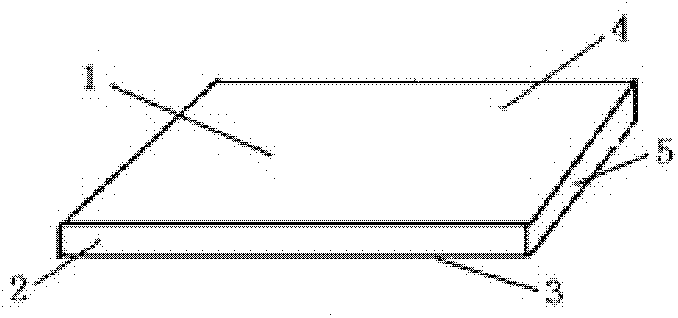

[0087] Figure 10 It is a schematic diagram of the side structure of a honeycomb-shaped high-efficiency energy-saving microstructure light guide plate for a 32-inch LCD TV. The light guide plate includes a colorless and transparent methyl methacrylate flat substrate 1 and a light incident side end surface 2 for receiving light into the interior , the other reflective side end faces 5 coated with a reflective film that are opposite to and intersected with the light incident side end faces, and the light that intersects with it is emitted from the light exit plane 4 and the bottom plane 3 with a scattering microstructure pattern opposite to the light exit plane 4 Composed, wherein the microstructure scattering three-dimensional pattern layer on the bottom plane 3 is coated with a layer such as Figure 5 A plurality of circular UV-cured colorle...

Embodiment 2

[0096] Embodiment 2, with reference to Figure 23 , 11 , 12, 17, 18, 19, 20, 3, 21, 27, 42 inch light guide plate and its LCD TV

[0097] Figure 11 It is a schematic diagram of the side structure of a honeycomb-shaped high-efficiency energy-saving microstructure light guide plate for a 42-inch LCD TV, including a colorless and transparent methyl methacrylate plate-type substrate 1, at least one light-incident side end surface 2 for receiving light into the interior, Opposite to and intersecting with the light-incident side end face, the rest of the reflective side end face 5 coated with a reflective film, and intersecting with it constitutes a light-emitting plane 4 that emits from the inside and a bottom plane 3 with a scattering microstructure pattern opposite to the light-emitting plane 4 , wherein the microstructure scattering pattern on the bottom plane 3 is coated with a layer such as Figure 5 The shown distribution pattern is used to adjust the brightness and unifo...

Embodiment 3

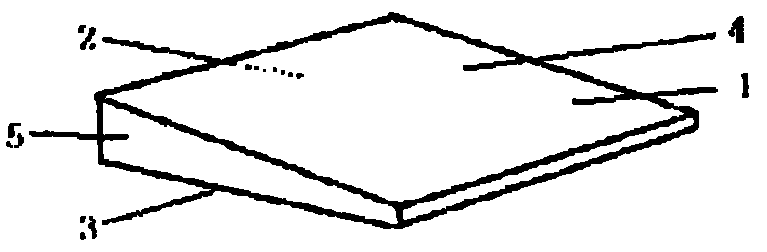

[0105] Embodiment 3: refer to Figure 24 , 2 , 13, 14, 15, 16, 20, 21, 27, 14 inch light guide plate and its notebook computer

[0106] Figure 24 It is a 14-inch colorless and transparent PC wedge-shaped substrate 1 (such as figure 2 ) is a schematic diagram of the side structure of a honeycomb-shaped high-efficiency energy-saving microstructure light guide plate for a notebook computer. The light guide plate includes a colorless and transparent wedge-shaped PC substrate 1, at least one light-incident side end surface 2 for receiving light entering the interior, and a light-incident side end surface The other opposing and intersecting reflective side end faces 5 coated with reflective film, and the light exit plane 4 emitted from the interior by the intersecting light and the bottom plane 3 with a scattering microstructure pattern opposite to the light exit plane 4 are composed of the bottom plane 3 The microstructure scattering three-dimensional pattern layer on the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com