Temperature measuring device for heat-conducting medium in thin film production equipment

A heat-conducting medium and production equipment technology, applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, etc., can solve the inconvenience of maintenance of film production equipment, the difficulty of ensuring uniform standards of quality, and the time-consuming sealing and installation Solve problems such as laboriousness, and achieve the effect of simple structure, convenient use, and guaranteed sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

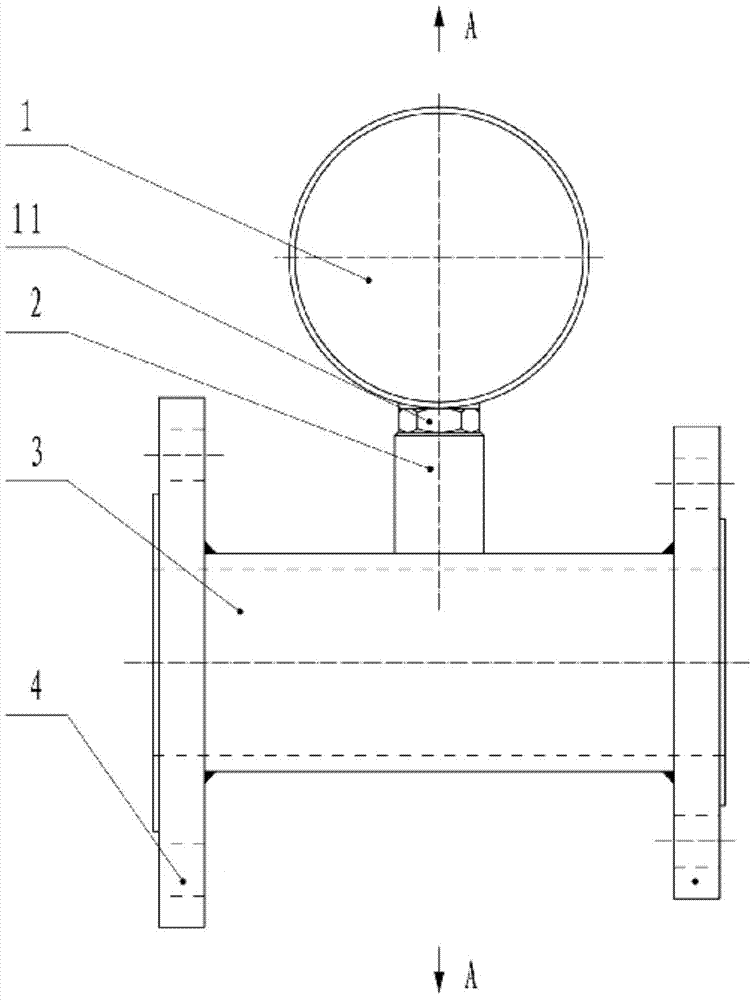

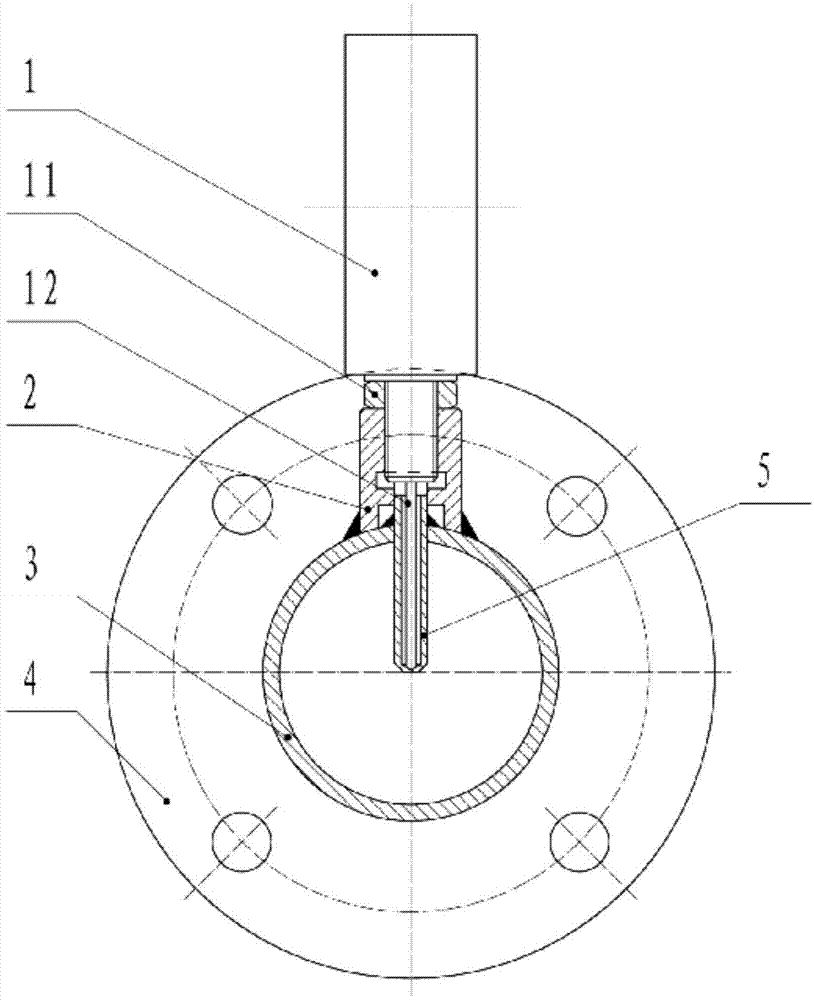

[0018] The temperature measuring device of the heat conduction medium in the film production equipment is as follows: figure 1 , 2 As shown, it includes a thermal resistance thermometer 1, a temperature measuring tube 5 and an installation tube 3.

[0019] The nozzles at both ends of the installation pipe 3 are sealed and welded to the flange 4 matched with the heat transfer medium pipe of the film production equipment, the open end of the temperature measurement pipe 5 is sealed and welded to the wall of the installation pipe 3, and the closed end of the temperature measurement pipe 5 is inserted into the installation pipe 3 Inside. In this example, the bottom end of the temperature measuring tube 5 is located on the centerline of the installation tube 3 . The temperature measuring tube 5 of this example is a copper tube.

[0020] The joint 2 coaxial with the temperature measuring tube 5 is welded on the installation pipe 3, the outer wall of the upper end of the thermal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com