Packaging and code printing integrated automatic equipment for condiments

An automatic equipment and integrated technology, applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of opening the packaging bags of seasoning packets, affecting the sealing quality of packaging bags of seasoning packets, and increasing the production cost of seasonings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

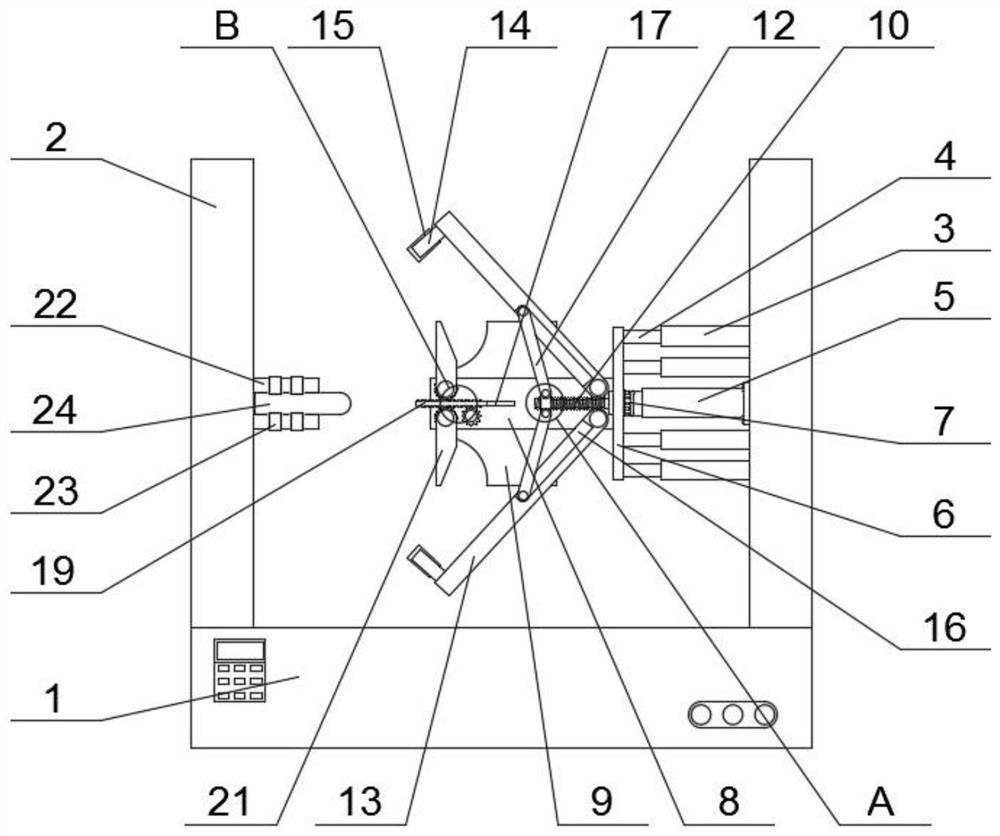

[0026] Embodiment one, with reference to Figure 1-5, a seasoning packaging coding integrated automation equipment, including a machine base 1, two sets of racks 2 installed on the upper end of the base 1 and symmetrically distributed, a rack plate 22 installed on one of the racks 2, rotatably connected to the rack The driving roller 23 on the plate 22 and the clamping mechanism 24 slidingly connected between two sets of frame plates 22, the inner end of the other set of frame 2 is equipped with a hydraulic rod 5, and the free end of the hydraulic rod 5 is fixedly connected with a hanging plate 6. The end of the hanging plate 6 far away from the hydraulic rod 5 is fixedly connected with the mounting base 8, and the outer end of the mounting base 8 is installed with two sets of glue nozzles 9 that are symmetrically distributed, and the outer end of the mounting base 8 is far away from the side of the hanging plate 6 Two groups of support arms 21 that are symmetrically distribut...

Embodiment 2

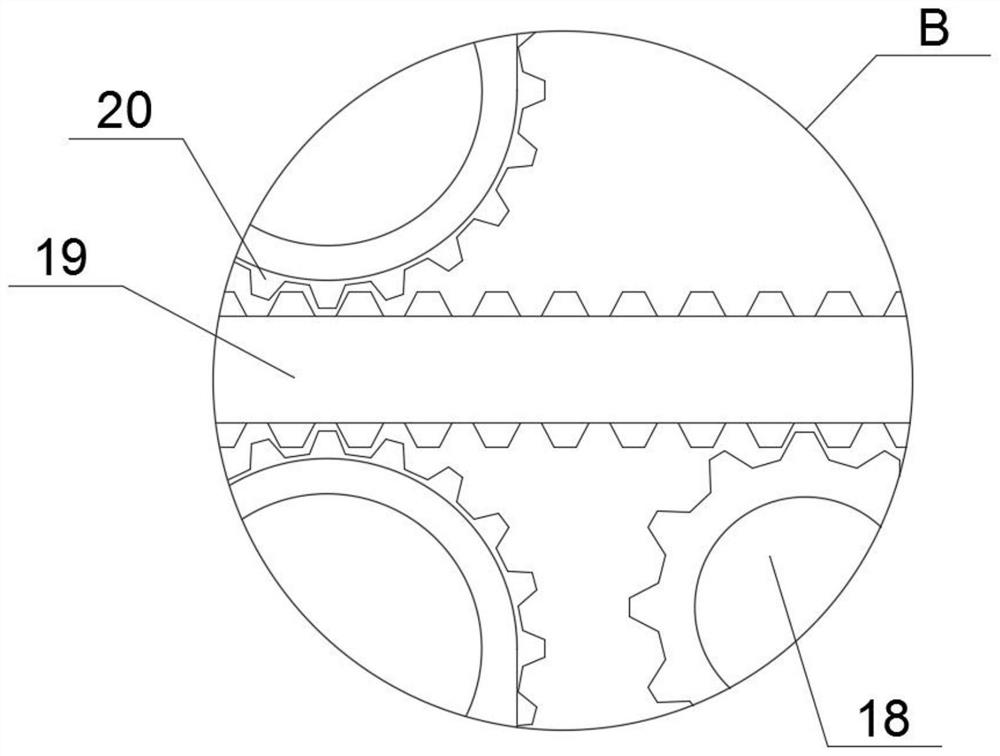

[0027] Embodiment two, refer to figure 1 , image 3 , Figure 4 with Figure 5 , the outer end of the mounting base 8 is rotatably connected with a drive gear 18, the inside of the base 1 is equipped with a motor that cooperates with the transmission of the drive gear 18, and the outer end of the base 1 is slidably connected with a rack 19, and the rack 19 is connected to the drive gear 18 Mesh connection, the inner ends of the two groups of support arms 21 are fixedly connected with the driven gear 20 on the outside of the rotating shaft, and the driven gear 20 is meshed with the rack 19, and the motor located inside the mounting seat 8 drives the drive gear 18 to rotate, and then drives The rack 19 meshed with the drive gear 18 slides in reverse along the slide rail 17 to the outside of the frame 1. When the rack 19 slides in the horizontal direction, it drives the two sets of driven gears 20 meshed with it to perform synchronous reverse rotation. Rotate, the driven gear ...

Embodiment 3

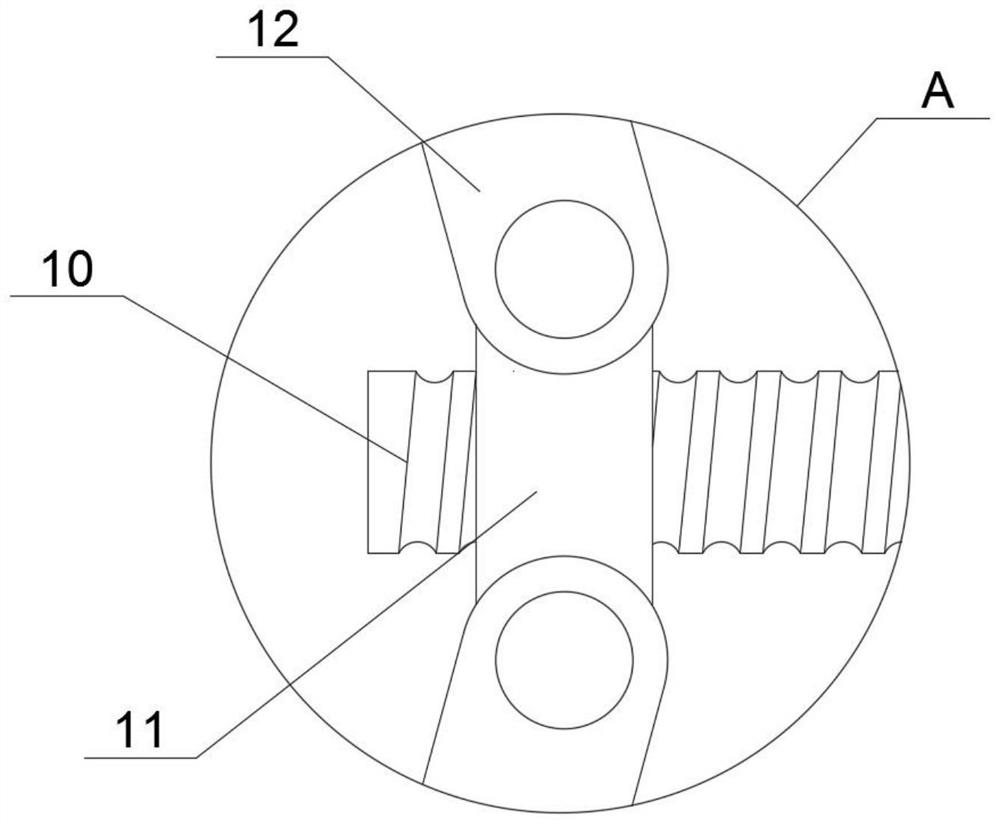

[0028] Embodiment three, refer to figure 1 , the outer end of the mounting base 8 is fixedly connected with a slide rail 17 that cooperates with the rack 19 to slide, and the inside of the clamp arm 13 has a turning groove 16 that cooperates with the rotation of the clamp arm 13. The setting of the slide rail 17 makes the sliding of the rack 19 more stable , to prevent the rack 19 from falling off the mounting seat 8 during the transmission process, the setting of the turning groove 16 is located on the pole 12 to provide a turning space, so that the device runs smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com