Wire cutting device for electronic circuit board welding

An electronic circuit board and cutting device technology, applied in the directions of printed circuits, printed circuit manufacturing, and assembling printed circuits with electrical components, can solve the problems of spending a lot of time, manpower and material resources, failing to improve work efficiency, and increasing working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

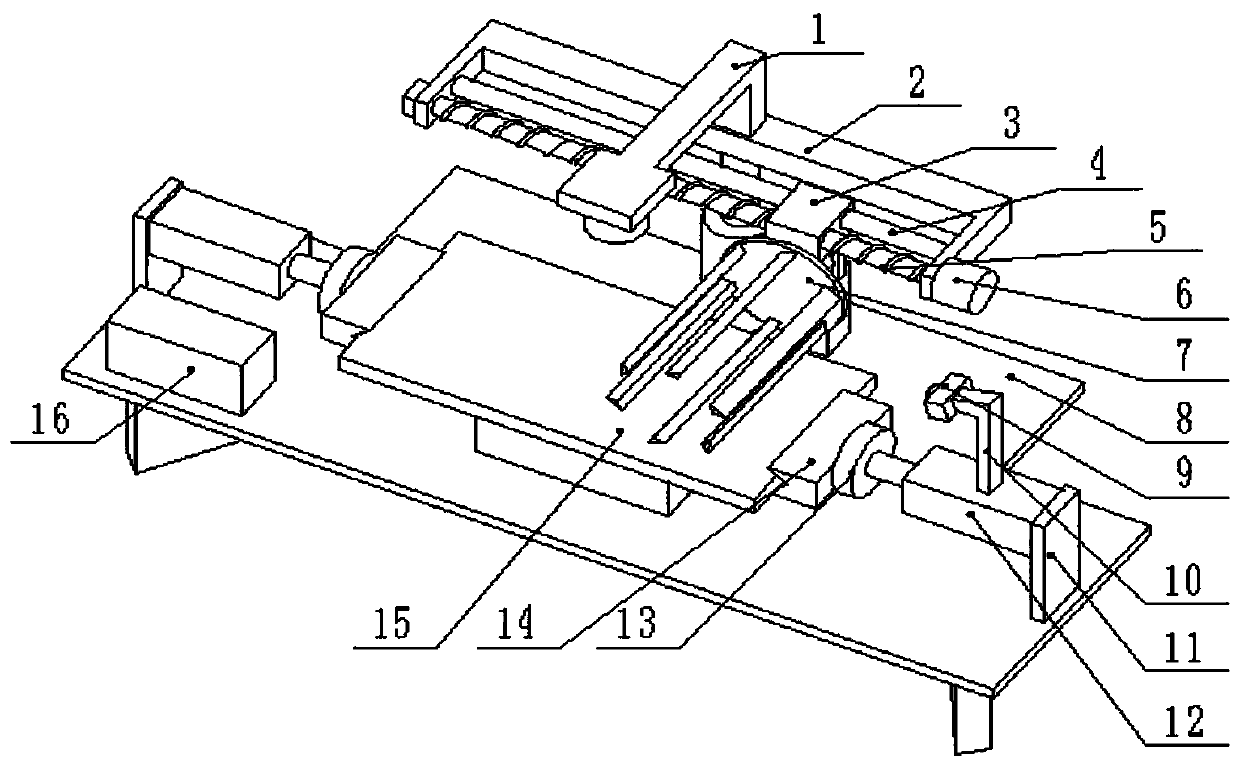

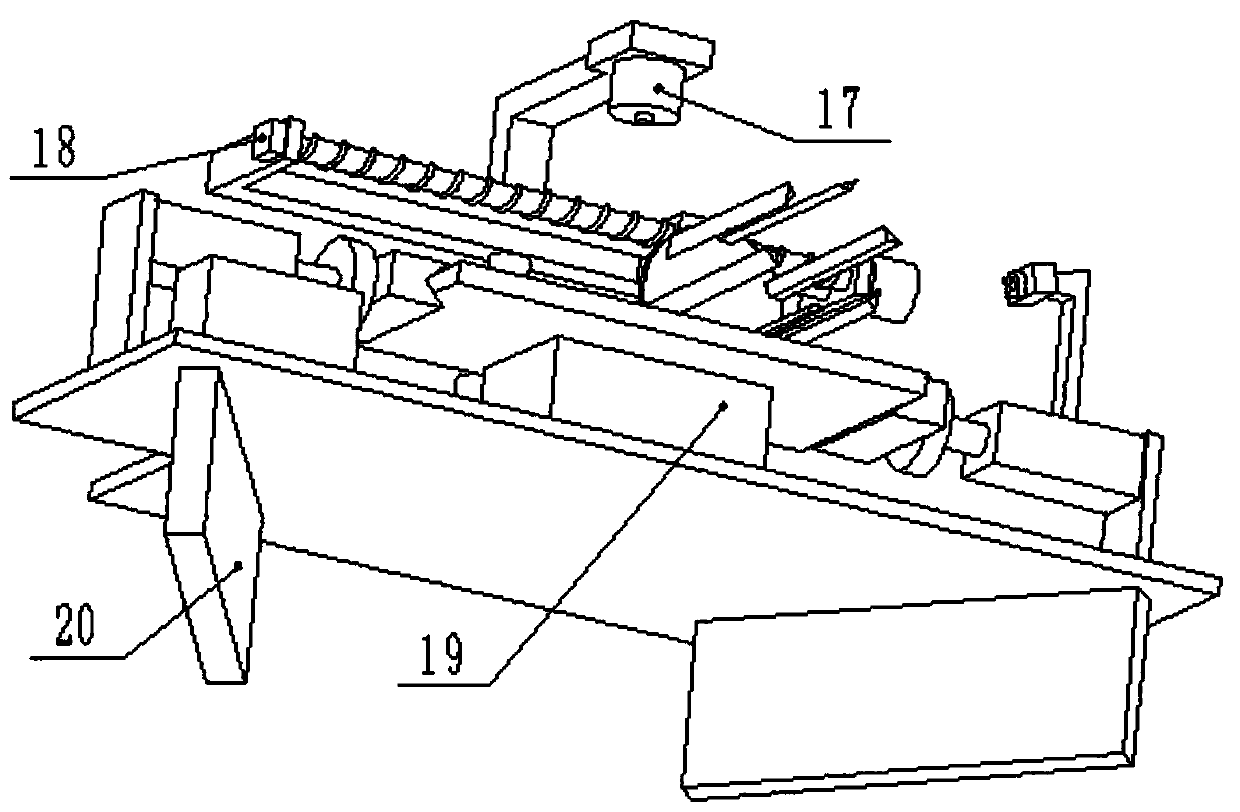

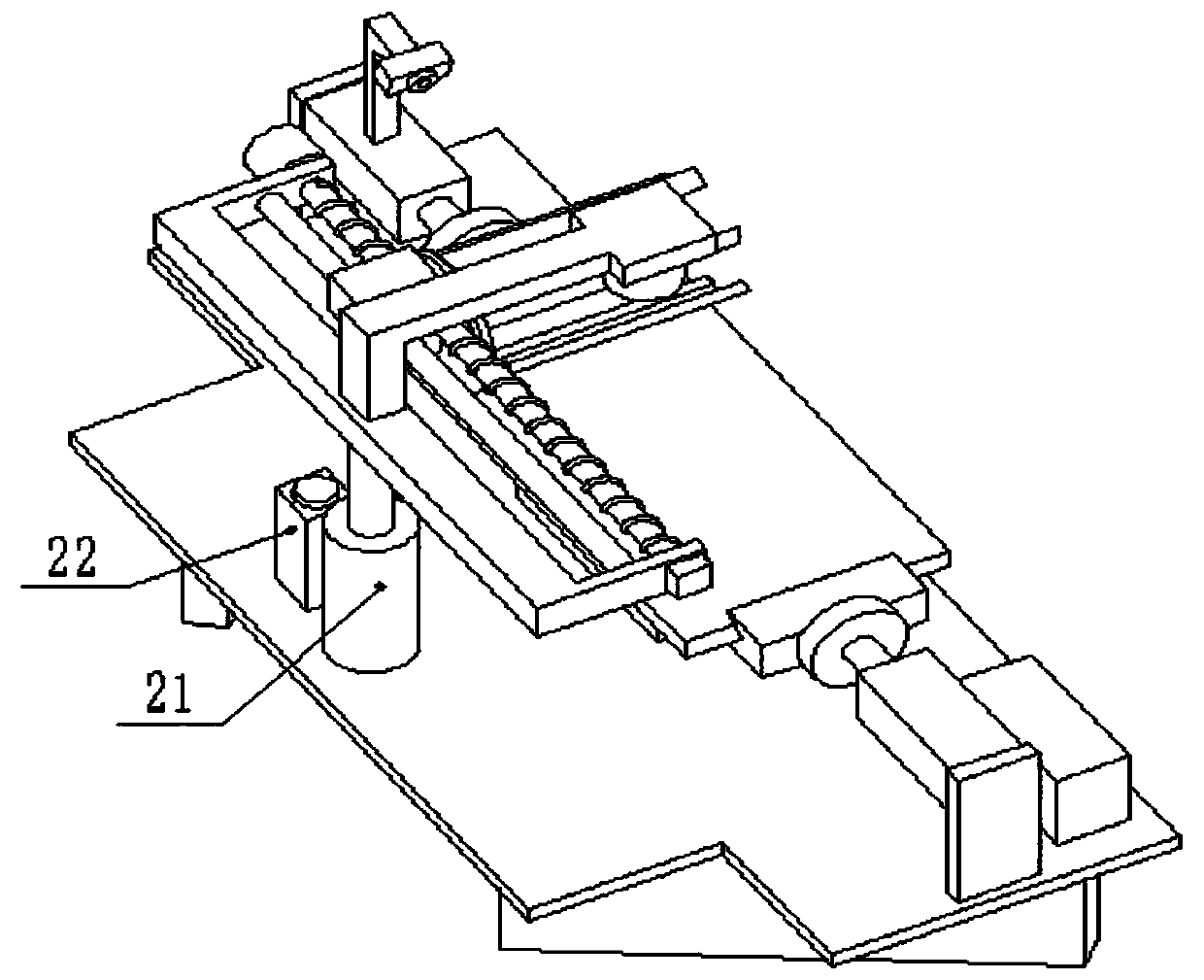

[0017] The present invention is achieved through the following technical solutions: a wire cutting device for electronic circuit board welding, comprising a first bracket 1, a second bracket 2, a slider 3, a slide rail 4, a lead screw 5, a first motor 6, a cutting Device 7, workbench 8, camera 9, camera base 10, hydraulic cylinder base 11, first hydraulic cylinder 12, pressure sensor 13, push block 14, processing plate 15, controller 16, first ultrasonic sensor 17, code device 18, support table 19, legs 20, second hydraulic cylinder 21, second ultrasonic sensor 22 and second motor 23, the lower part of the workbench 8 is fixedly connected with the legs 20, and the upper side of the workbench 8 is fixed There are hydraulic cylinder bases 11, the number of which is 2, the front left side of the workbench 8 is fixedly connected to the controller 16, the upper middle of the workbench 8 is fixedly connected to the support platform 19, and the inner side of the hydraulic cylinder bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com