Roller cone disc type continuously variable transmission

A continuously variable transmission, cone-disc technology, applied in belts/chains/gears, friction transmission devices, elements with teeth, etc., can solve problems such as reducing geometric slip rate, accelerating traction surface wear, and small transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0130] The present invention will be described in further detail below according to accompanying drawing and embodiment:

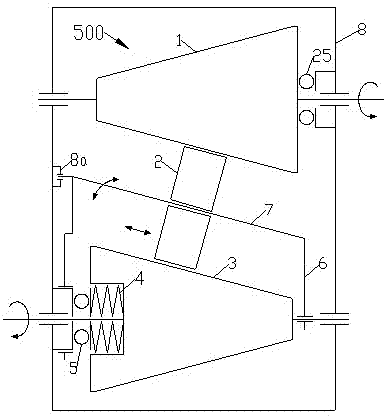

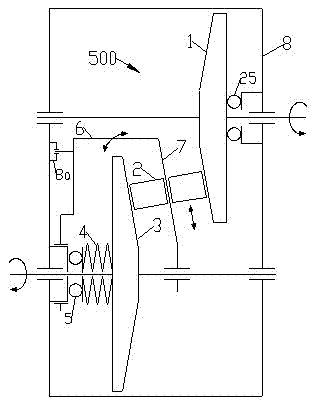

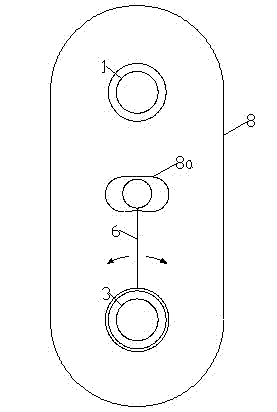

[0131] Such as figure 1 , figure 2 , image 3 As shown, the roller-cone-disc continuously variable transmission of the present invention includes a bevel wheel support 8, at least one transmission wheel set 500 and at least one pressurizing device 4, and the transmission wheel set 500 includes a driving bevel wheel 3, at least one driven bevel wheel 1 , the roller bracket 6, the roller 2 corresponding to the number of the driven cone wheel 1, the guide device 7 corresponding to the number of the roller 2; the taper directions of the driving cone wheel 3 and the driven cone wheel 1 are oppositely set, and the adjacent taper lines are kept Parallel, the driving cone wheel 3 and the driven cone wheel 1 are rotationally connected with the cone wheel bracket 8 respectively; the pressurizing device 4 is set at the large diameter end of the taper of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com