Hydraulic Control System for Transmissions with Parallel Planetary Gear Trains

A technology of hydraulic control system and planetary gear train, which is applied to fluid pressure actuators, servo motors, transmissions, etc., and can solve problems such as low control accuracy, high failure rate, and slow response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

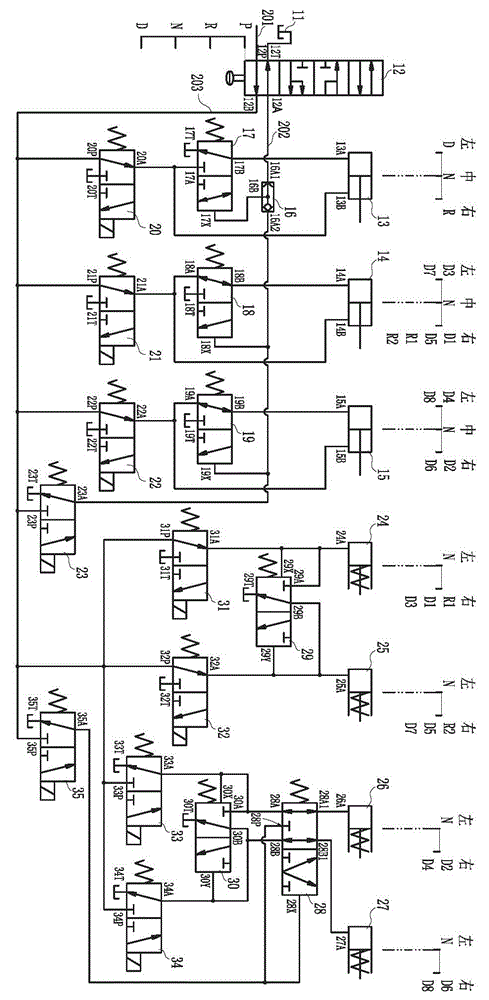

[0025] see figure 1 , the hydraulic control system for the transmission of the parallel planetary gear train includes three double-acting oil cylinders, respectively the first two-way oil cylinder 13, the second two-way oil cylinder 14 and the third two-way oil cylinder 15; four one-way acting oil cylinders, respectively the first two-way oil cylinder A one-way oil cylinder 24, a second one-way oil cylinder 25, a third one-way oil cylinder 26 and a fourth one-way oil cylinder 27; a shuttle valve 16; three externally controlled 2-position 3-way slide valves, respectively the first slide valve 17. The second spool valve 18 and the third spool valve 19; the externally controlled 2-position 5-way parking valve 28; two 2-position 3-way interlock valves, respectively the first interlock valve 29 and the second interlock valve Lock valve 30; nine 2-position 3-way electromagnetic reversing valves, respectively the first electromagnetic reversing valve 20, the second electromagnetic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com