Method of liquefaction resistance processing of filament reinforced sandy soil

A fiber filament, anti-liquefaction technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of low shear strength, poor anti-vibration liquefaction performance, and short service life of short-filament fiber reinforced lime soil , to achieve strong anti-static and anti-dynamic liquefaction performance, good economic performance, simple and reliable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

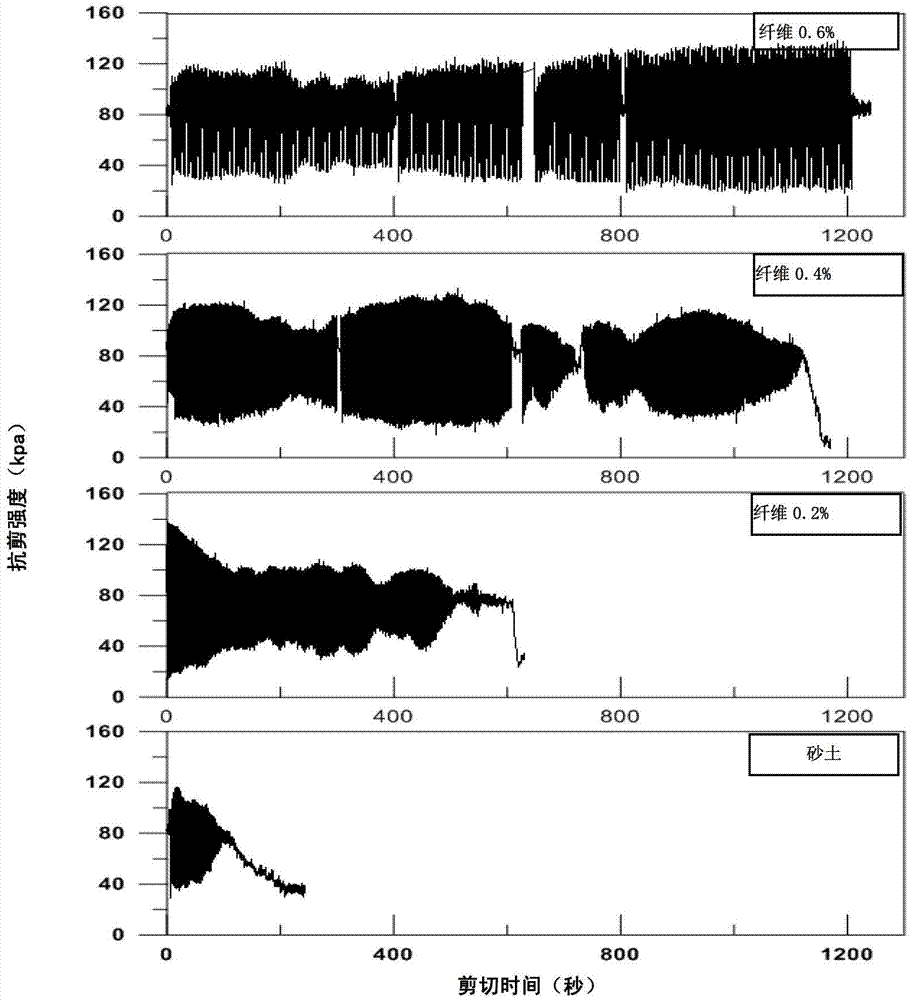

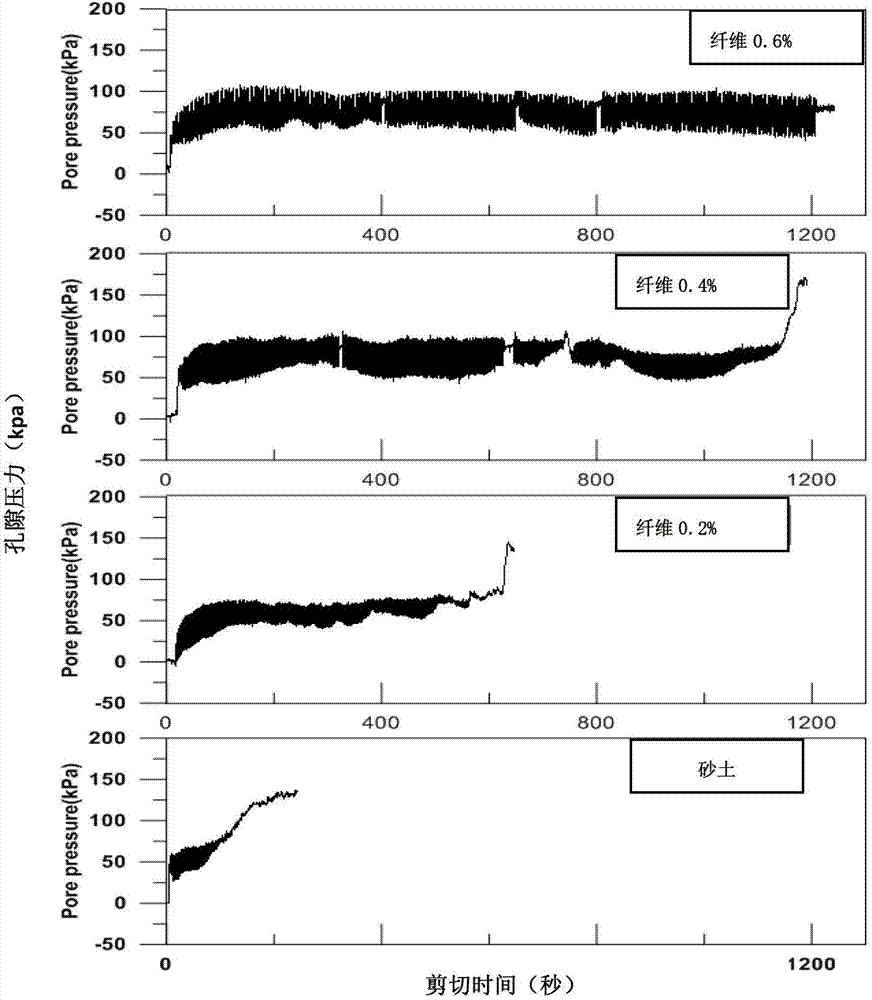

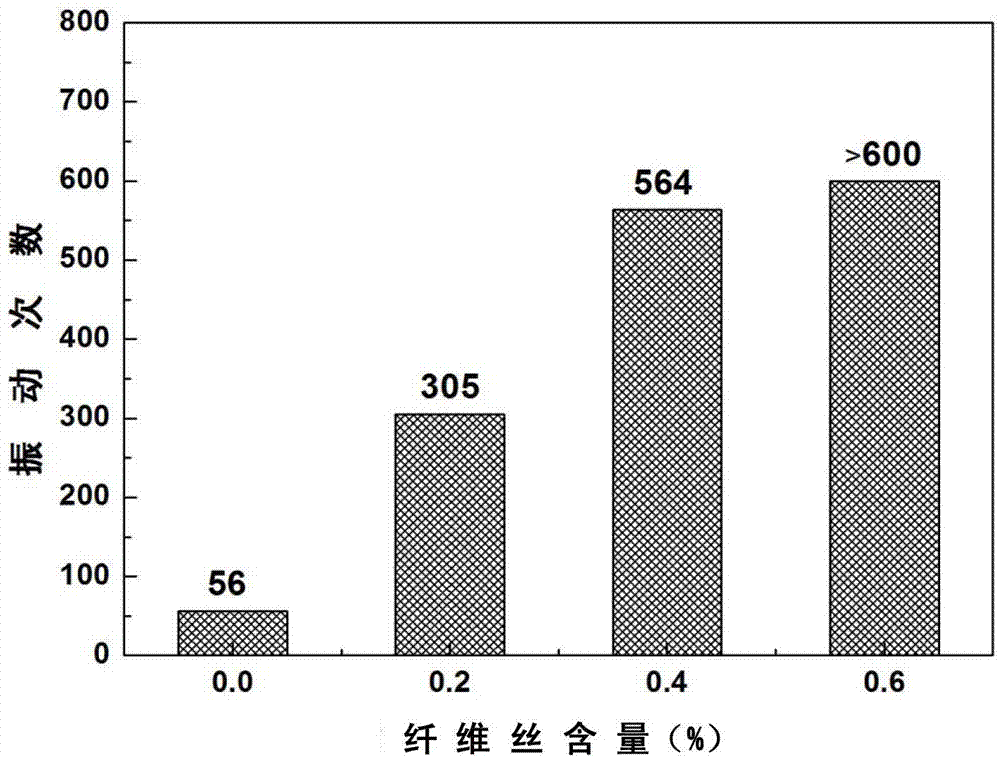

[0019] The invention proposes a method for anti-liquefaction treatment of fiber-reinforced sandy soil, which uses fiber-reinforced sand to improve the sand, thereby obtaining the finished product of fiber-reinforced sandy soil. The specific steps are as follows:

[0020] Step 1, raw material preparation: choose polypropylene fiber, polyethylene fiber, polyurethane fiber or polyester fiber as the fiber filament, the physical and mechanical properties of the fiber filament are: average length 31-50mm, diameter 0.03-0.1mm, specific gravity 0.9- 0.98, tensile strength ≥ 400Mpa, elastic modulus ≥ 4000 Mpa, and good dispersion, the content of the fiber filament is 0.2-0.8% dry sand weight; the sand is made of siliceous sand, particle size 0.074 ~ 2mm, specific gravity 2.65. The maximum dry density is 1.6 g / cm, and the sand and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com