Alpha-silane cross-linked polypropylene and application thereof as 3D printing material

A cross-linked polypropylene and silane cross-linking technology, applied in the field of cross-linked polypropylene, can solve the problems of reduced strength and slow cross-linking speed, and achieve the effect of low cost and important industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

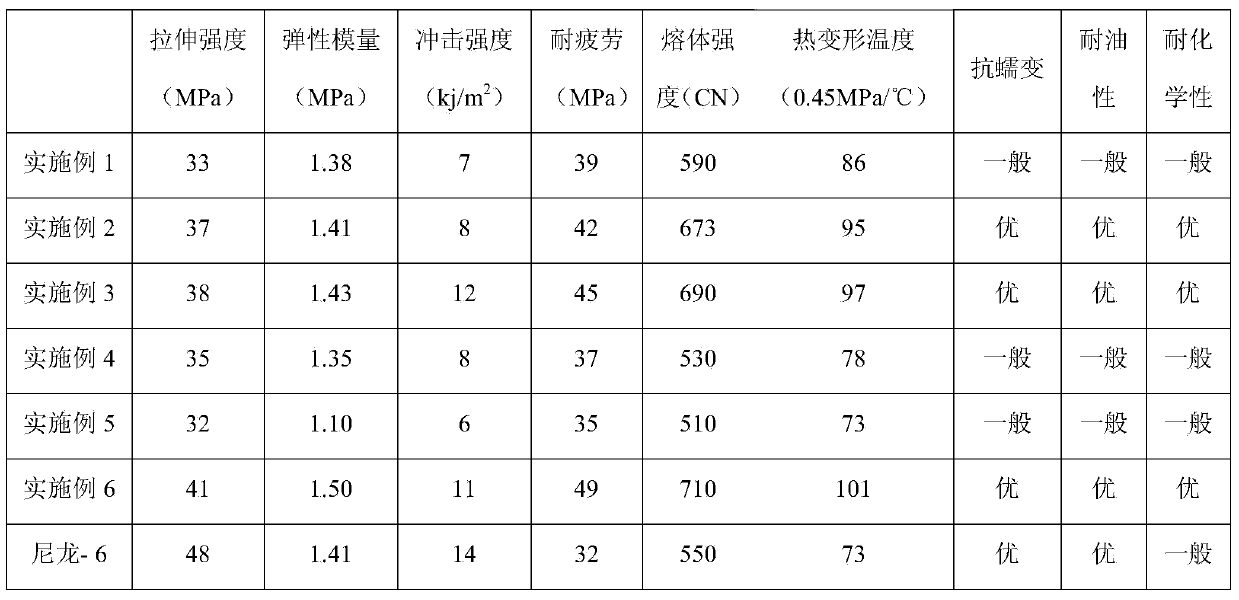

Examples

Embodiment 1

[0039] Polypropylene pellets 100 parts

[0040] Diethylpropylbenzene peroxide (DCP) 0.20 parts

[0041] 4.0 parts of α-methacryloyloxymethyltrimethoxysilane;

[0042] Keep the temperature below 15°C and under the protection of nitrogen, mix the above components thoroughly, and then send them to a twin-screw extruder with an aspect ratio of 36 for extrusion, and the speed of the twin-screw extruder is 30r / min; The temperature of each zone is: 160-170°C in the feeding section, 190-200°C in the melting section, 190-200°C in the mixing section, 170-190°C in the exhaust section, 160-180°C in the homogenizing section, and the feeding speed is 15 kg / hour .

Embodiment 2

[0044] Polypropylene powder 100 parts

[0045] Benzoyl peroxide (BPO) 0.25 parts

[0046] 5.0 parts of α-methacryloyloxymethyltriethoxysilane;

[0047]Keep the temperature below 25°C and under the protection of nitrogen, mix the above components thoroughly, and then send them into a twin-screw extruder with an aspect ratio of 36 for extrusion, and the speed of the twin-screw extruder is 50r / min; The feeding section is 150-160°C, the melting section is 190-200°C, the mixing section is 190-200°C, the exhaust section is 170-190°C, the homogenization section is 160-180°C, and the feeding speed is 10 kg / hour.

Embodiment 3

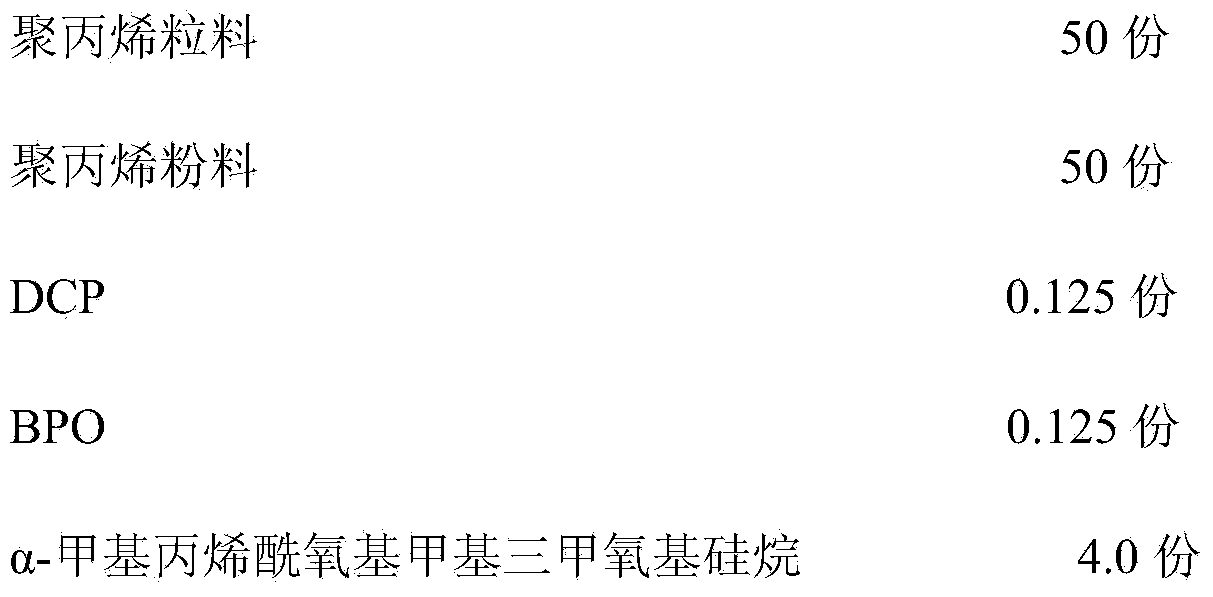

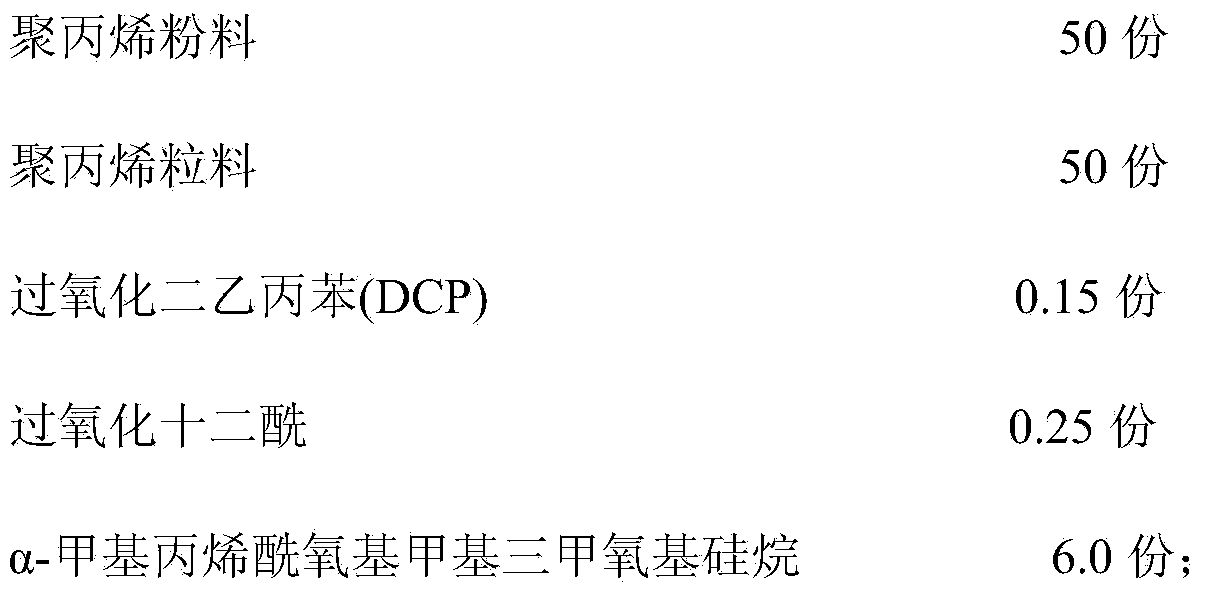

[0049]

[0050] Keep the temperature below 15°C and under the protection of nitrogen, fully mix the above components, and then feed them into a twin-screw extruder with an aspect ratio of 36 for extrusion, and the speed of the extruder is 45r / min; Section 150-170°C, melting section 190-200°C, mixing section 190-200°C, exhaust section 170-190°C, homogenization section 160-180°C, and the feeding rate is 12 kg / hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com