The method of spheroidization of hexanitrohexaazaisopentazane explosive

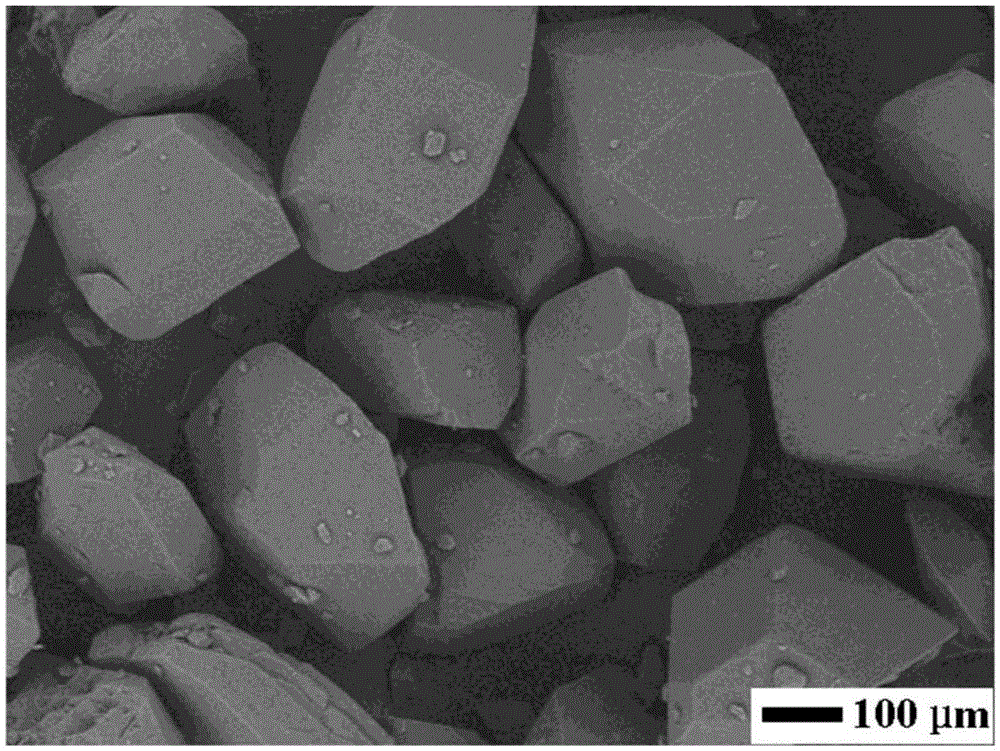

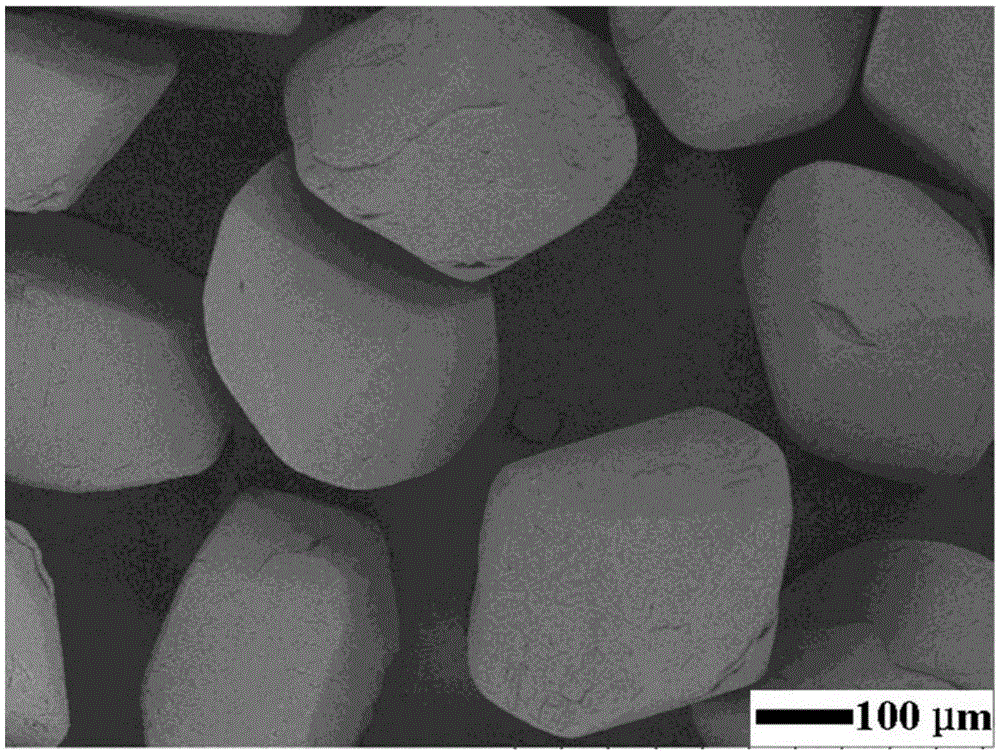

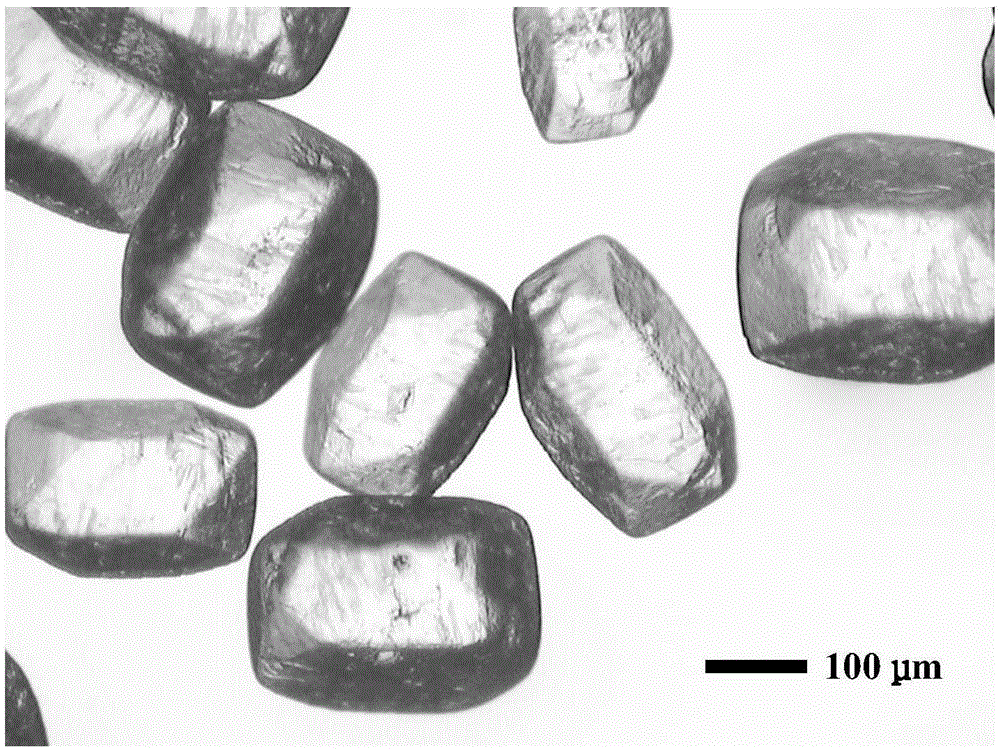

A technology of zaisopentazane and hexanitrohexanitrogen, which is applied in the field of spheroidization of hexanitrohexaazaisopentazane explosives, can solve the problems that CL-20 explosive crystals are not applicable, and achieve less defects and higher production efficiency. High rate, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 30g of dimethyl sulfoxide and 50g of distilled water, mix well, add 5.0g of CL-20 raw material into the mixed solvent, stir at 40°C and 600rpm for 180min, filter the feed solution, wash with distilled water, After drying, add the solid product to 30 g of ethanol, stir at room temperature at 500 rpm for 60 min, filter, wash with distilled water, and dry to obtain 4.4 g of spherical CL-20 product. The analysis shows that the crystal density after spheroidization is 2.0381g / cm 3 , The mechanical sensitivity test has a characteristic drop height of 49.4cm.

Embodiment 2

[0032] Weigh 30g of dimethyl sulfoxide and 60g of distilled water, add 0.1g of polyvinylpyrrolidone, dissolve and mix evenly, add 5.0g of CL-20 raw material into the mixed solvent, stir at 45°C and 500rpm for 60min, After filtering the material liquid, washing with distilled water for more than 3 times, and drying, add the solid product into 30g of ethanol, stir at room temperature at 500rpm for 60min, filter, wash with distilled water, and dry to obtain spherical CL- 20 products 4.5g. The analysis shows that the crystal density after spherification is 2.0364g / cm 3 , The mechanical sensitivity test has a characteristic drop height of 45.3cm.

Embodiment 3

[0034] Weigh 30g of butyl acetate and 500g of isooctane, add 0.1g of polyvinyl alcohol, dissolve and mix evenly, then add 40.0g of CL-20 raw material into the mixed solvent, stir at 60°C and 500rpm for 300min, After filtering the material liquid, washing with distilled water for more than 3 times, and drying, add the solid product to 400g of ethanol, stir at room temperature at 350rpm for 60min, filter, wash with distilled water, and dry to obtain spherical CL- 20 products 36.8g. The analysis shows that the crystal density after spheroidization is 2.0380g / cm 3 , the mechanical sensitivity test has a characteristic drop height of 41.5cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com