A method for opening a three-way pipe mold

A tee pipe and mold technology, applied in the field of plastic molds, can solve the problems of shortage, prolonging the mold production cycle, difficulty in meeting the requirements of large-scale, precise, complex, and long-life mold manufacturing, and achieve the reduction of overall volume and compact mold structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

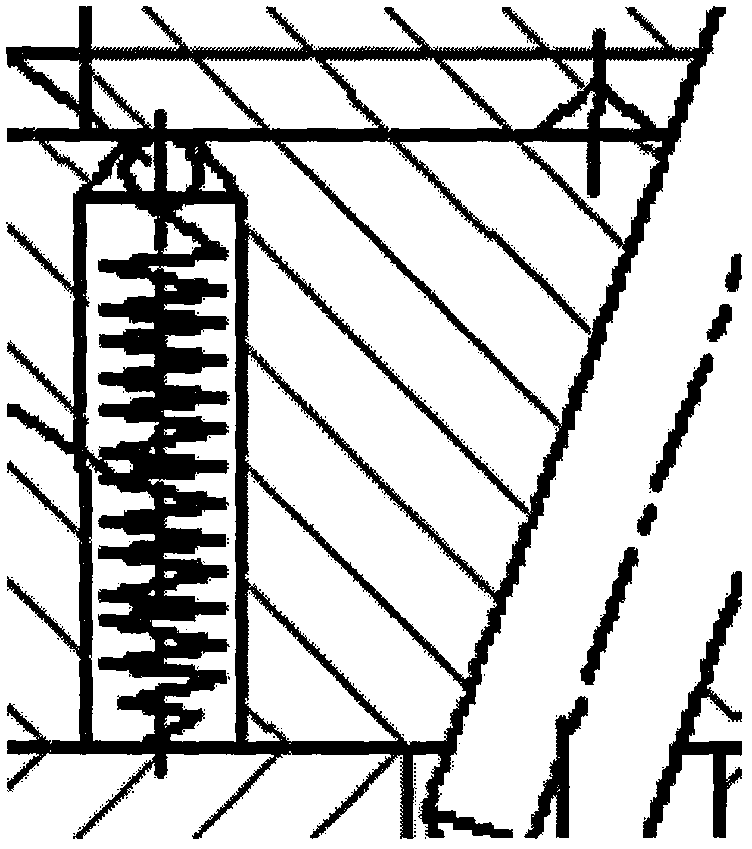

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings .

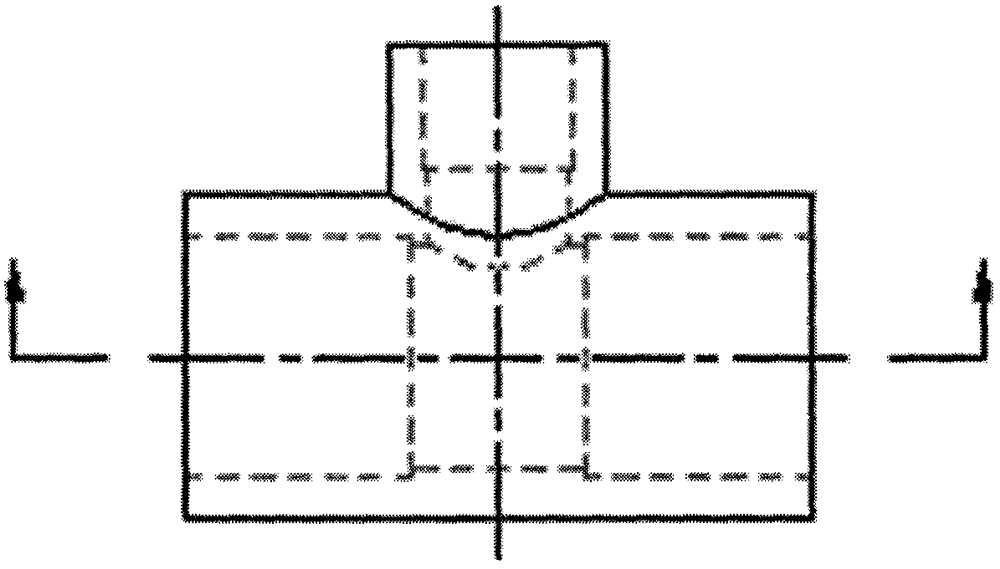

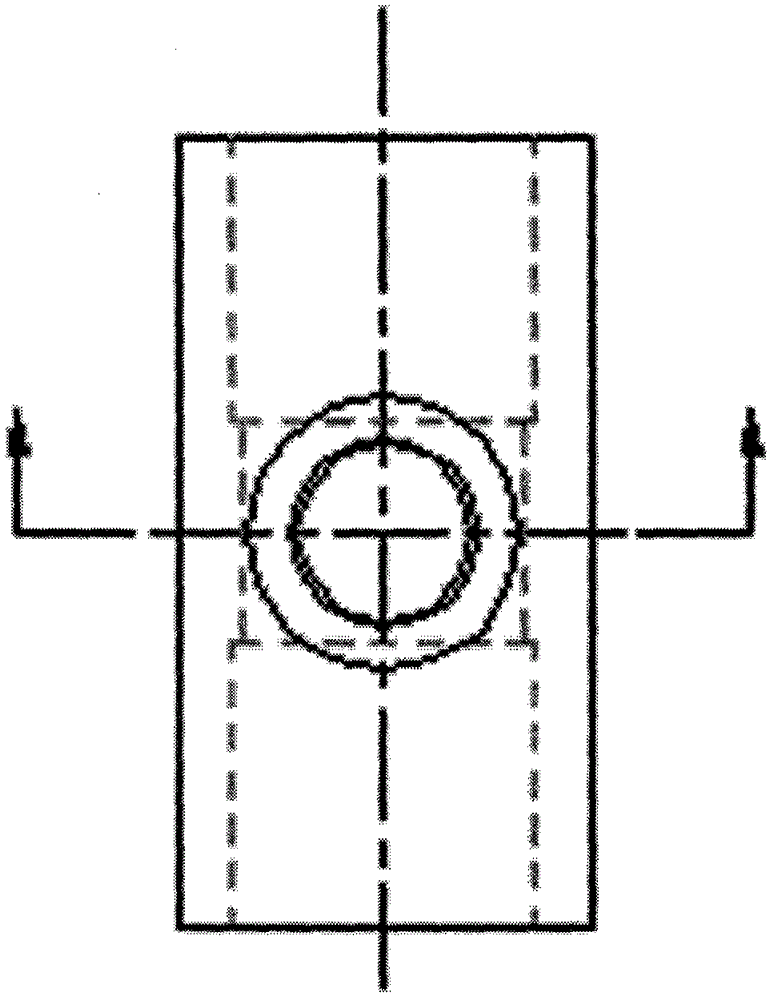

[0035] The invention provides a mold opening method for a three-way pipe mold, which can realize a standardized, miniaturized and high-quality three-way pipe mold that meets modern technological requirements, and is suitable for injection molding of the three-way pipe. The mold-opening method of the present invention is described below according to the steps of each stage.

[0036] 1. Determine the plastic materials used for injection molding by analyzing the functional requirements, use environment and technical indicators of tee pipe plastic parts.

[0037] Functional requirements mean that plastic parts sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com