Data collection implementation method of semiconductor manufacturing equipment

A technology for data collection and manufacturing equipment, applied in the direction of electrical components, transmission systems, etc., can solve the lack of a secure communication mechanism for SECS/GEM communication, communication security cannot be guaranteed, and SECS/GEM communication methods cannot meet the needs of equipment and user data collection and other issues to achieve the effect of improving equipment data collection capabilities and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] The present invention is oriented to the data collection realization method of semiconductor manufacturing equipment and comprises the following steps:

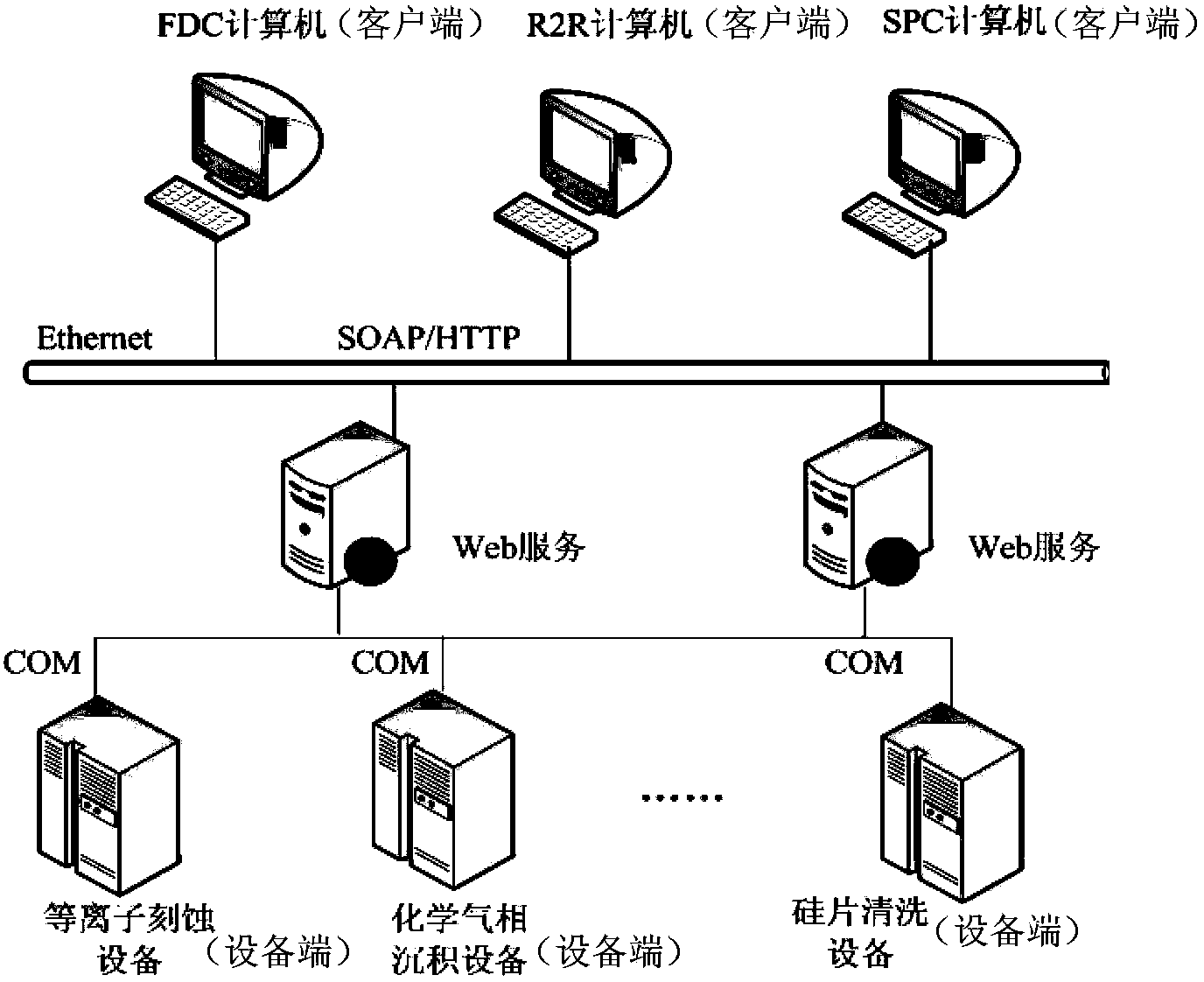

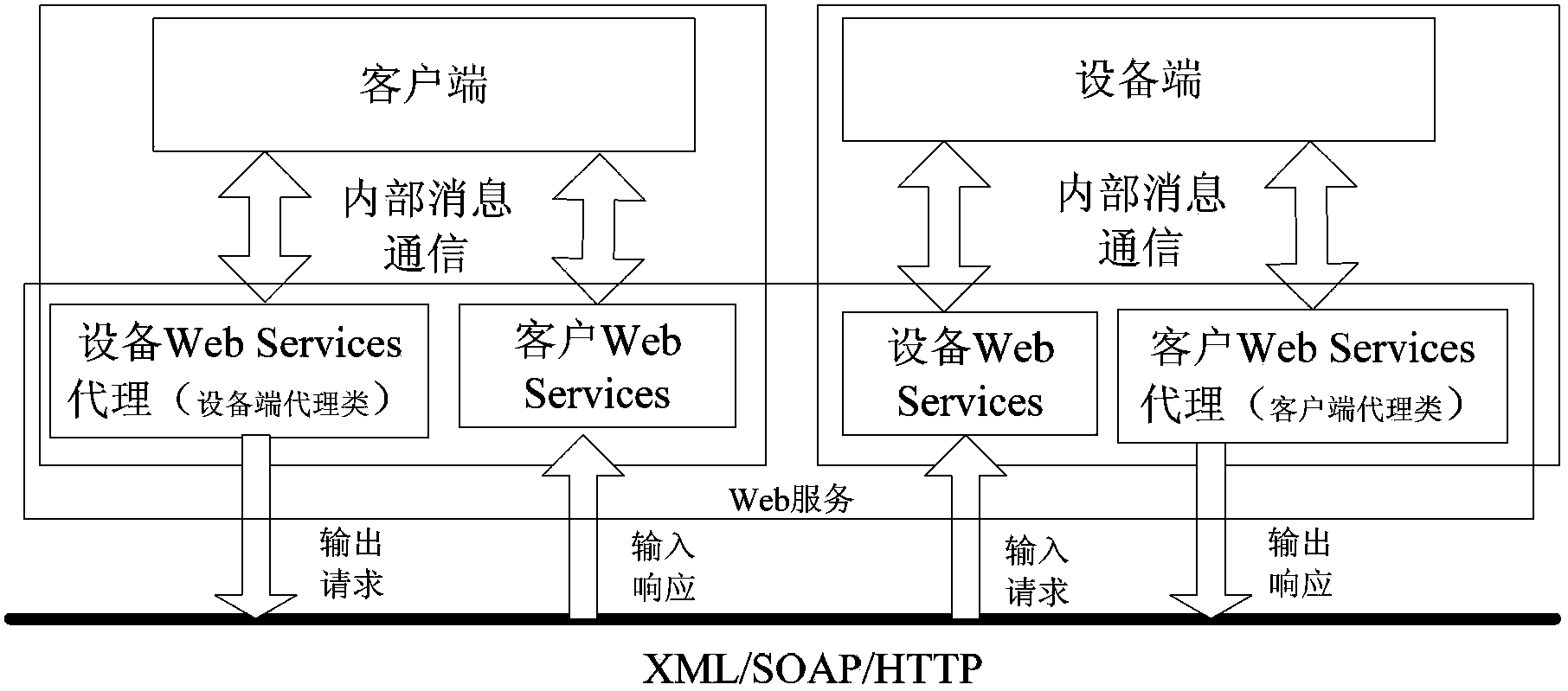

[0040] 1) figure 1 Flowchart for data collection. The data collection steps are: establish a Web service on the device side and the client side, and use the proxy class to realize the service connection, realize the call to the interface service provided by the device side; call the device authentication interface, and the client side and the device side use the secure socket layer protocol Client security authentication, exchange information with each other, and create SOAPHeader data messages to ensure the security of data communication between the device and the client; the client defines and sends a data collection plan based on the information it cares about the device for use in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com