Automatic battery assembly system

An automatic battery assembly technology, which is applied in battery assembly machine, secondary battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve the problems of large human error, low degree of automation, and high production cost, so as to improve assembly accuracy and save manpower Effects of increased cost and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

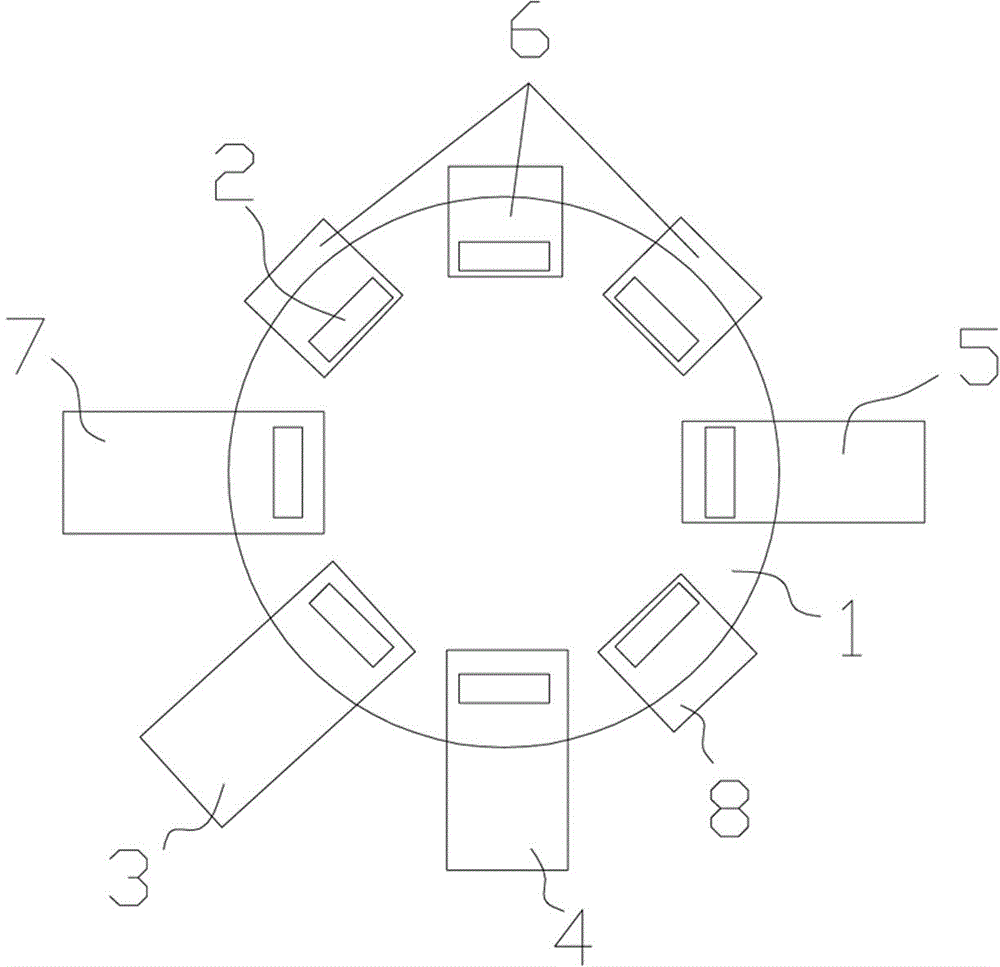

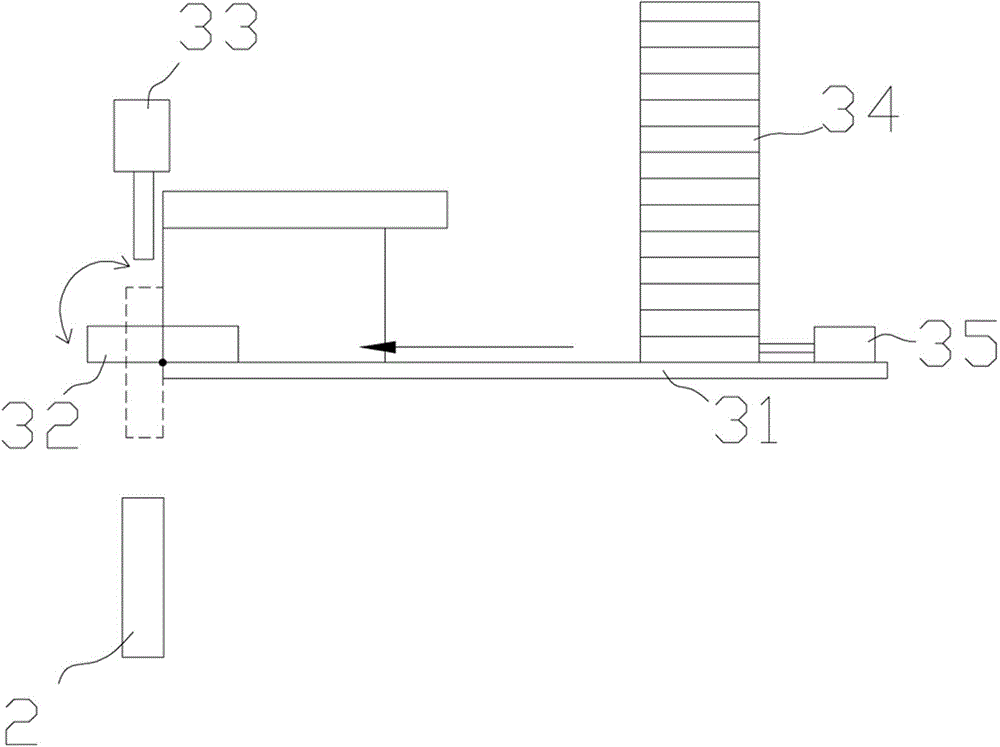

[0022] refer to figure 1 , the battery automatic assembly system of the present invention includes a turntable 1, an assembly fixture 2, a cell feeding mechanism 3, a cell protection plate cutting and feeding mechanism 4, a nickel strip punching and feeding mechanism 5, a spot welding mechanism 6, and a cell Blanking mechanism 7 etc., also preferably comprise protective plate flattening mechanism 8 between cell protective plate cutting feeding mechanism 4 and nickel strip punching feeding mechanism 5, for the protective plate pressing of loading is adjusted to at the default position.

[0023] Turntable 1 rotates in a stepwise manner parallel to the horizontal plane, figure 1 The direction of rotation in is counterclockwise. The assembly fixture 2 is installed on the turntable 1, rotates with the turntable 1, and enters the cell feeding mechanism 3, the cell protection plate cutting and feeding mechanism 4, the protection plate flattening mechanism 8, and the nickel strip pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com