Preparation method of vanadium electrolyte

A technology of electrolyte and electrolyte solution, which is applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems of not using, the influence of vanadium batteries and electrolyte electrochemical performance and thermal stability, etc., and achieve the improvement of solubility and utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the vanadium electrolyte according to the present invention and the additives used in the method will be described in detail below.

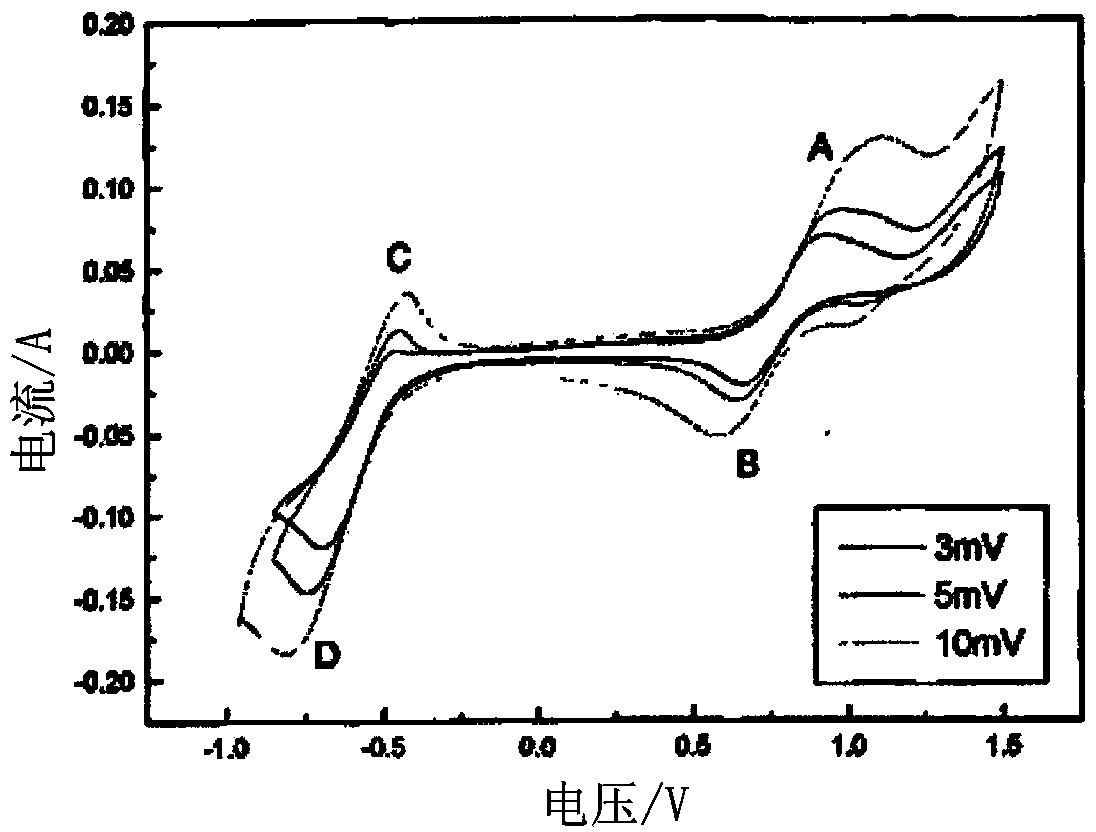

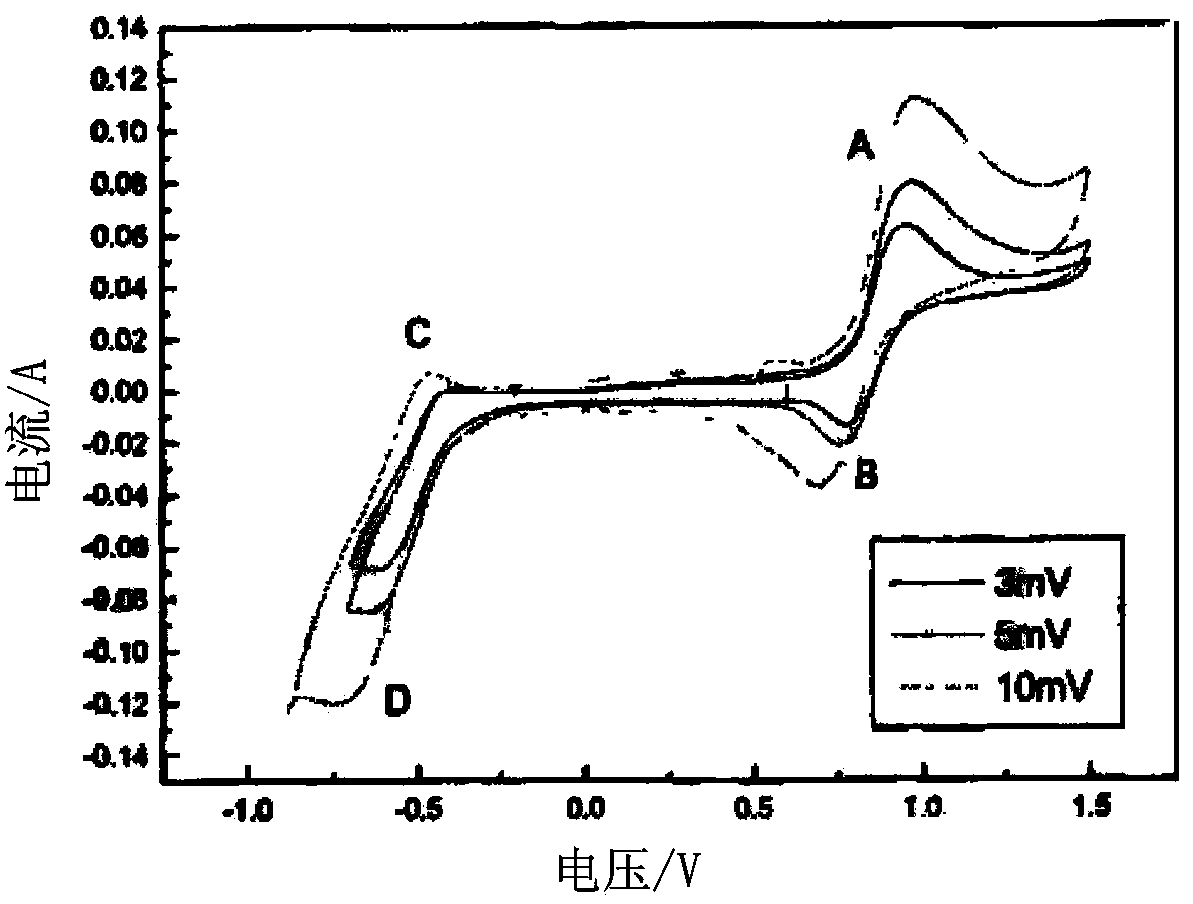

[0019] According to an embodiment of the present invention, a method for preparing a vanadium electrolyte, the method includes the following steps: (i) dissolving vanadium pentoxide powder in concentrated sulfuric acid for activation, adding it to deionized water for dissolution and filtration, Obtain a pentavalent vanadium ion solution; (ii) use the pentavalent vanadium ion solution as the negative electrode electrolyte solution, and use the sulfuric acid solution as the positive electrode electrolyte solution, and perform electrolysis to obtain trivalent vanadium and tetravalent vanadium with a molar ratio of 1:1. Vanadium ion electrolyte solution, wherein, the sulfuric acid in the positive electrode electrolyte and the sulfuric acid in the negative electrode electrolyte solution have the same molar weight; (iii...

Embodiment 1

[0028] V 2 o 5 : High-grade pure (above 99.9%)

[0029] h 2 SO 4 : Analytical pure, d=1.84g / mL

[0030] h 3 PO 4 : Analytical pure, d=1.834×10 3 kg / m 3

[0031] (i) Weigh 320g of high-purity vanadium pentoxide, dissolve it in 160mL of concentrated sulfuric acid, and activate it for 10 minutes. Under stirring conditions, slowly add the activated vanadium in a muddy form to deionized water, add water to dissolve to 1L, Filtrate to obtain pentavalent vanadium solution.

[0032](ii) Measure 160mL of concentrated sulfuric acid, slowly add it into deionized water under stirring conditions, and dissolve to obtain 1L of sulfuric acid solution. The pentavalent vanadium solution obtained through the above step (i) is added to the negative electrode of the electrolytic cell as an electrolyte, and the prepared sulfuric acid solution is added to the positive electrode of the electrolytic cell as an electrolyte. The current of electrolysis is 20A, the electric quantity of electro...

Embodiment 2~4

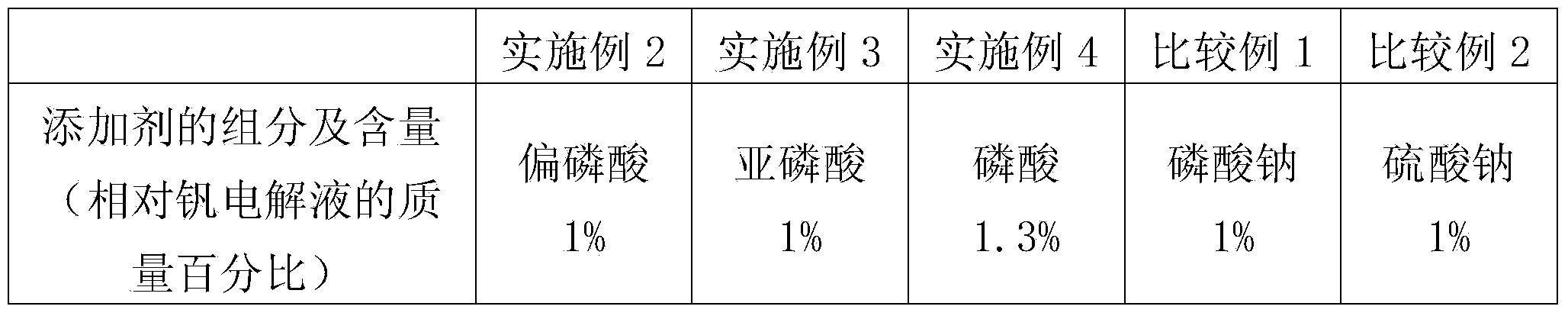

[0037] Steps (i) and (ii) are the same as the above-mentioned Example 1, and the additives shown in Table 1 are respectively added in Step (iii) as Examples 2-4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com