Computer-assisted plotting method for waste heat boiler pipes

A computer-aided, waste heat boiler technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of wasting time, two-dimensional and three-dimensional inconsistencies, etc., to reduce the error rate, improve time, and liberate productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

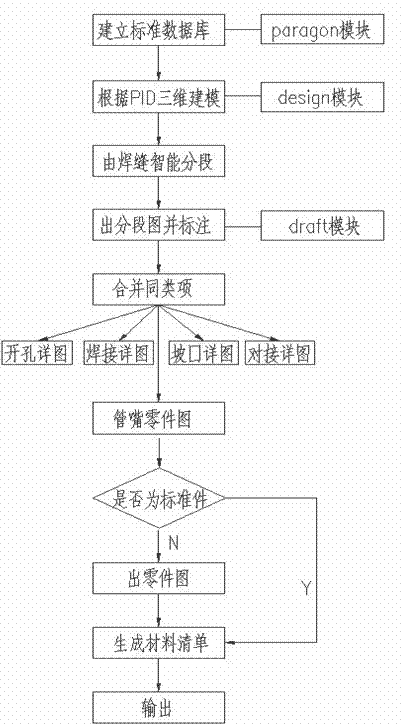

[0039] See Figure 2 to Figure 7 ,

[0040] 1. Establish a database: firstly, determine which parameters are required by the component, and divide the parameters into external input parameters, internal calculation parameters and output parameters according to the requirements. For example, the saddle type pipe joint, its external input parameters are the outer diameter, wall thickness, height, etc. of the pipe joint; the internal calculation parameters are the main pipe radius, main pipe opening value, etc.; the output parameters are the pipe joint inner diameter, welding height, welding width, tc Wait. Give each type of pipe fittings a letter code, and the code should be clear from the name. To facilitate the selection of designers.

[0041] 2. Establish a symbol library: The detailed drawings on general pipeline drawings are mainly divided into pipe joint opening drawings, pipe joint welding drawings, pipe fitting butt joint drawings, and groove detailed drawings. Make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com