Closed circulation system for sealing and collecting oil fog of generator

A circulatory system and generator technology, applied in the direction of engine lubrication, hydropower, engine components, etc., can solve problems such as discount of oil mist collector effect, or improper maintenance, unreasonable selection, etc., to prevent pollution of generators. and the effect of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

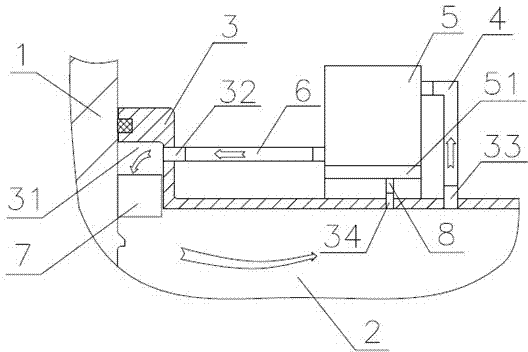

[0028] As the best embodiment of the present invention, with reference to the attached figure 2 A sealing cover 3 is arranged on the upper part of the oil tank 2, an annular cavity 31 is arranged on the upper part of the sealing cover 3, and one or several air inlet holes 32 are arranged on the inner surface of the annular cavity 31, and one or several exhaust holes 33 are arranged on the plane of the sealing cover And the oil return hole 34, the exhaust hole 33 is connected with the oil mist collector 5 through the oil mist pipe 4, the oil mist collector 5 is directly placed on the sealing cover or the oil tank cover, the outlet of the oil mist collector is connected to the exhaust gas discharge pipe 6 The sealing cover is connected to the air inlet 32, and the oil condensed by the oil mist collector is stored in the oil collection tank 51. The oil collection tank 51 is connected to the oil return hole 34 through the oil return pipe 8, and a check valve is installed on the oi...

Embodiment 2

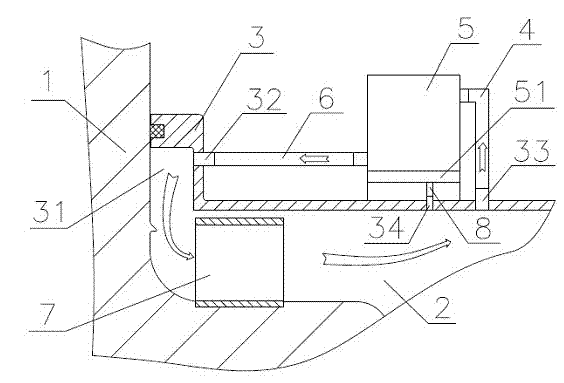

[0034] As another preferred embodiment of the present invention, refer to figure 1 , which includes the rotating parts of the thrust bearing or guide bearing of the generator, the oil tank surrounding the rotating parts, the upper part of the oil tank is provided with a sealing cover, and the sealing structure provided between the sealing cover and the rotating parts isolates the oil tank from the outside world, and the sealing structure can be Contact seal structure, gap seal structure, seal seal structure or comb-tooth seal structure, the seal cover is respectively opened with an air intake hole, an exhaust hole and an oil return hole communicating with the oil tank, and the rotating parts A fan is provided on the top to guide the airflow from the air inlet to the exhaust hole. The fan is located between the rotating part and the sealing cover. An oil mist collector is arranged on the sealing cover or the cover of the oil tank. The oil mist collector absorbs the oil mist The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com