Wool opening and mixing technology in cashmere carding process

A cashmere and carding technology, which is applied in the field of cashmere opening and wool (velvet), can solve the problems of insufficient addition of crude oil, excessive addition of crude oil, and waste of crude oil, etc., to prevent The effects of loosening hair, eliminating static electricity, and optimizing processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

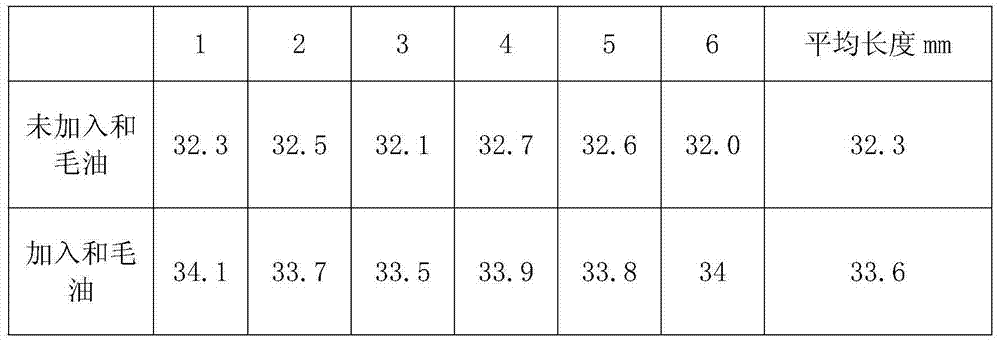

Examples

Embodiment 1

[0023] Embodiment one, a kind of technique of cashmere opening and wool in carding process, it comprises the following steps:

[0024] S1 Water-washed cashmere rehydration once: Lay the washed cashmere evenly, each layer is 8-10cm, and spray 0.07% oil-water mixture evenly on each layer for 10 minutes;

[0025] S2 velvet stuffing: the water-washed velvet that has regained moisture once is stuffed, and the time is 12-24 hours in summer and 12-48 hours in winter;

[0026] S3 Opening: The washed fleece after stuffing is opened with a wool machine, and the fluff is fully shaken to a fluffy state, and the fluff is fed evenly. The feeding amount is controlled at 300kg / h, and the thickness does not exceed 6-10cm. ;

[0027] S4 Secondary moisture regain: Test the washed cashmere raw materials that have been opened, and perform a secondary moisture regain on the washed wool that is 24-28% lower than the moisture regain on the machine, and calculate the amount of water added during the ...

Embodiment 2

[0037] Embodiment 2, it differs from Embodiment 1 only in that: the water-washed velvet is replenished once and the step of regaining moisture is evenly layered with water-washed velvet, each layer is 8-10 cm, and 0.08% oil-water mixture is evenly sprayed on each layer , the time is 15min.

Embodiment 3

[0038] Embodiment 3, which differs from Embodiment 1 only in that: in the opening step, the washed fleece after velvet is opened by a knitting machine, and the fluff is fully shaken to a fluffy state, and the fluff is evenly fed, fed The amount is controlled at 200kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com