Method for manufacturing large-aperture high-strength gathering and transportation seamless steel tube for environment with high content of hydrogen sulfide

A high hydrogen sulfide-containing, seamless steel pipe technology is applied in the field of corrosion-resistant materials and oil and gas transportation, which can solve the problems of specification range limitation, achieve the effects of reducing residual stress, ensuring uniformity, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for manufacturing a large-diameter high-grade seamless gathering and transportation pipe for high-hydrogen-sulfide-containing environments of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0025] The present invention provides a method for manufacturing a large-caliber high-grade steel-grade seamless gathering pipe for an environment with high hydrogen sulfide content, the method comprising the following steps:

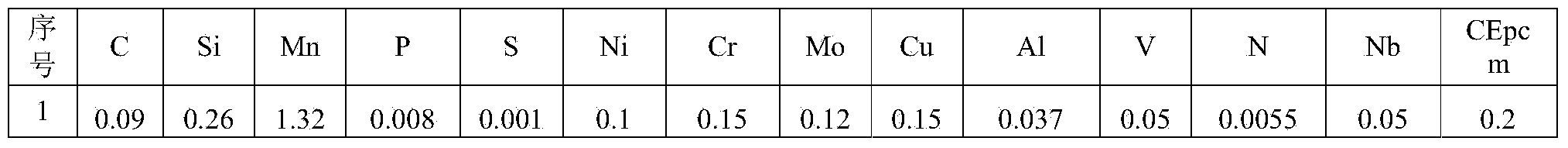

[0026] a. The steel type composition weight % of the large-diameter high-grade seamless gathering and transportation pipe for the high-hydrogen-sulfide-containing environment is: C0.05-0.13%, Si0.25-0.50%, Mn1.20-1.50%, P ≤0.015%, S≤0.003%, Al0.030~0.060%, N0.003~0.012%, Nb0.030~0.10%, V0.04~0.09%, Cu0.15~0.35%, Ni0.10~0.50% , Mo0.10~0.35%, Cr0.15~0.45%, Ca≤0.006%, CE ΠW ≤0.39%, CEpcm≤0.22%, the balance is Fe and unavoidable impurities;

[0027] b. Steelmaking is designed according to the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com