Fermentation production culture medium and culture method for aspergillus niger capable of selective synthesis of 1,3-diglyceride

A technology for the production of culture medium and diglyceride, which is applied in microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problem of low catalytic efficiency of whole-cell lipase, and achieves favorable conditions for industrial production, mild conditions, and high efficiency. Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The following are the culture medium and method involved in the present invention

[0024] (1) Seed medium: Seed medium (mass percentage): 0.3 beef extract; 0.5 peptone; 0.5 glucose; Bacteria for 20 min.

[0025] (2) Preparation of fermented seed liquid: Inoculate Aspergillus niger into the seed medium, culture at 30°C, 180r / min for 24 hours, and obtain the fermented seed liquid.

[0026] (3) Fermentation production medium (mass percentage): bean cake powder 2; corn steep liquor 2; K 2 HPO 4 0.5;NaNO 3 0.5; the rest is water, pH 7.0, in a 250mL Erlenmeyer flask, filled with 20%, and sterilized at 121°C for 20 minutes.

[0027] (4) Preparation of whole-cell lipase: Inoculate the fermented seed solution at 2% inoculum in the fermentation production medium for 72 hours at 30°C and 180r / min, then centrifuge at 4°C and 10,000r / min for 10min The obtained bacterium was freeze-dried and ground with liquid nitrogen protection to obtain whole-cell lipase.

[0028] (5) Gly...

Embodiment 2

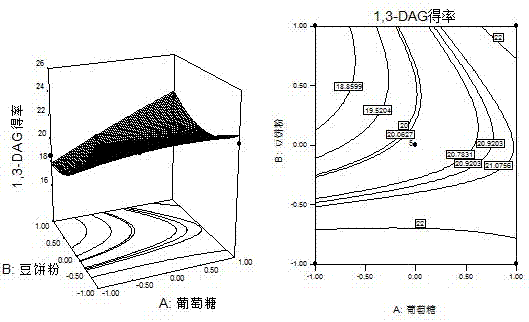

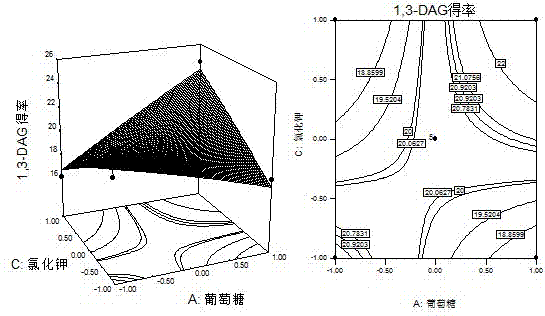

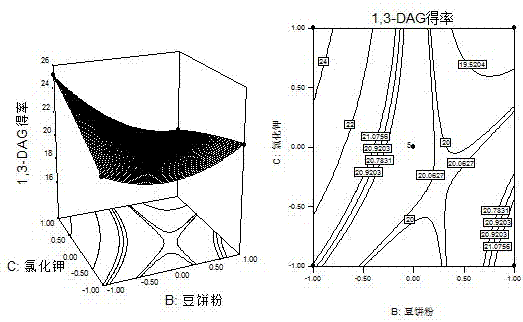

[0031] Box-Behnken design

[0032] Box-Behnken design is an experimental method suitable for optimization of 2-5 factors. Several factors screened by PB experiments that significantly affect the synthesis of whole-cell lipase of Aspergillus niger CCTCC No. M2012538 and the yield of 1,3-diglyceride were used as design factors, and the concentration obtained from the steepest climbing test was used as the center With the yield of 1,3-diglyceride as the response value, the composition of the medium was optimized through response surface analysis. See Table 1 for the experimental design, Table 2 for the experimental results, and Table 3 for the analysis of the experimental results.

[0033]

[0034] Adopt Design-Expert software to carry out analysis of variance and multiple regression fitting to the data of 1,3-diglyceride yield in Table 2, obtain the significance of each influence factor (Table 3), obtain Aspergillus niger CCTCC No. M2012538 The quadratic polynomial regressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com