Comprehensive utilization method for pomelo peels

A technology of pomelo peel and rind is applied in the field of comprehensive utilization of pomelo peel, which can solve the problems of single utilization of pomelo peel and complicated process, and achieve the effect of improving the utilization value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1. Coproduction prepares pomelo peel essential oil, pectin and adsorbent

[0023] (1) After washing the whole pomelo peel, separate the yellow outer skin from the white inner skin, dry the white skin in an oven at 50°C, weigh 117.5g of the yellow skin, and crush it in a grinder for 3 times, 15 seconds each time, Transfer to a three-necked bottle, add 0.5g of sodium chloride, then add deionized water until the solid is submerged by 1-2cm, carry out steam distillation, collect the fractions, and steam for about 3 hours until the steamed gas no longer has the fragrance of pomelo peel , stop the distillation, transfer the fraction to a separatory funnel, extract with anhydrous ether, and carry out rotary evaporation to the upper liquid to obtain 0.6902 g of pomelo peel essential oil, with a yield of 0.587%.

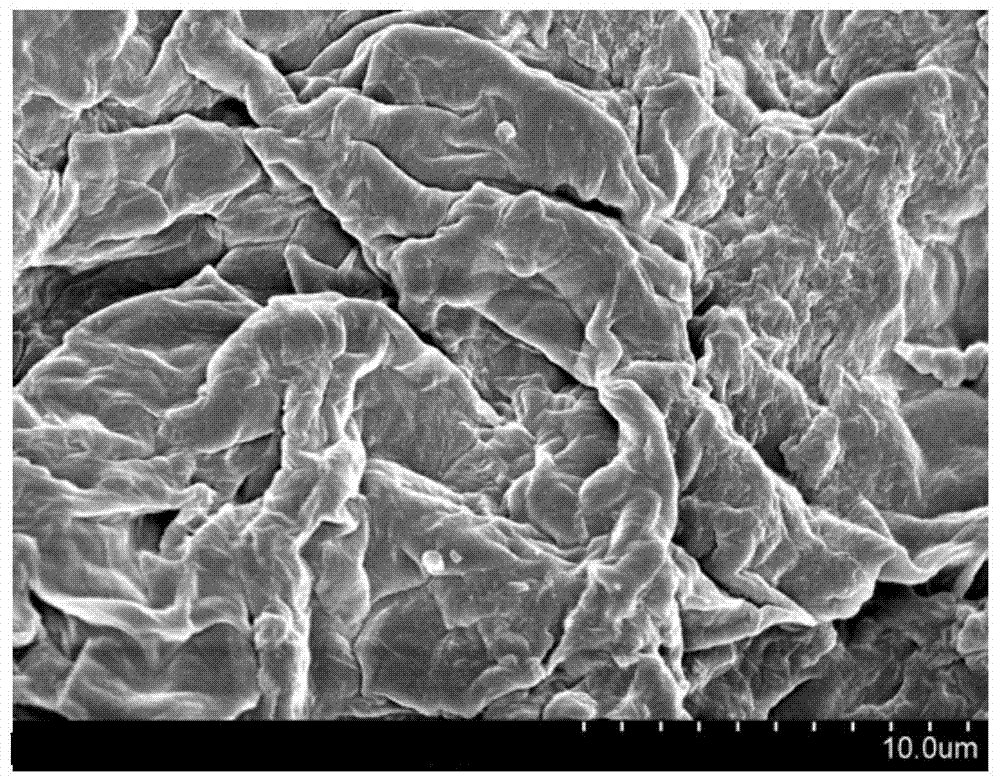

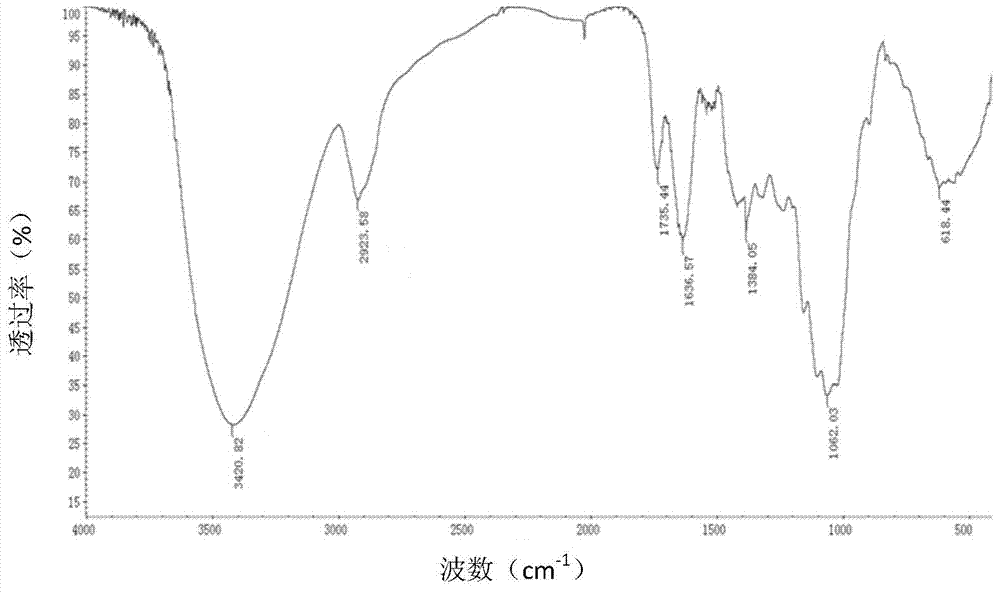

[0024] (2) Suction filter the yellow skin residue in (1), reflux with absolute ethanol to remove the pigment, then dry at 50°C, mix and pulverize with the w...

Embodiment 2

[0027] Embodiment 2. Coproduction prepares pomelo peel essential oil, pectin and adsorbent

[0028] (1) Wash a few pieces of pomelo peel and separate the yellow peel from the white peel. Dry the white peel in an oven at 60°C. The yellow peel weighs 50.3g. Put it in a grinder and grind it for 3 times, each time for 20 seconds, transfer To the three-neck flask, add 0.5g sodium chloride, then add deionized water until the solid is submerged by 1-2cm, carry out steam distillation, collect the fraction, steam for about 4 hours, stop the distillation, transfer the fraction to the separatory funnel, and use Extraction was carried out with anhydrous ether, and the upper liquid was subjected to rotary evaporation to obtain 0.219 g of pomelo peel essential oil, with a yield of 0.435%.

[0029] (2) Suction filter the yellow skin residue in (1), reflux with absolute ethanol to remove the pigment, dry at 60°C, mix and pulverize with the white skin for 3 minutes to obtain a mixed powder, we...

Embodiment 3

[0031] Example 3. Adsorption effect evaluation of residue adsorbent

[0032]Simulate dye waste water with methylene blue solution, take by weighing 0.9961g of 40~80 mesh residue adsorbents prepared in Example 1 in No. 1 conical flask, add 50.0ml of crude methylene blue solution of 1000mg / L, and add to another conical flask ( Add 50.0ml of the same solution to No. 2), place the two bottles in a constant temperature oscillator at 25°C and 150r / min for 24 hours, take them out, absorb the solution and centrifuge, take the supernatant, dilute 200 times and 500 times respectively to measure the absorbance , Determine the concentration from the standard curve, and calculate the concentration of the solution before and after adsorption to be 1073.7mg / L and 221.6mg / L respectively. The removal rate of the methylene blue solution by the residue adsorbent is 79.4%, and the adsorption capacity is 42.8mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com