Synthetic method of MgSAPO-31 molecular sieve

A synthesis method, the technology of mgsapo-31, is applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., which can solve the problem of easy formation of miscellaneous crystals in crystallization products, and achieve flexible modulation and high acid site density. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: the synthetic method of present embodiment MgSAPO-31 molecular sieve is implemented according to the following steps:

[0023] 1. Disperse NaX molecular sieves in magnesium nitrate solution or magnesium acetate solution, and perform ion exchange at a temperature of 50-80 ° C. The number of exchanges is 1-4 times, and each exchange is 1-6 hours to obtain Mg / NaX molecular sieves;

[0024] Two, the mass fraction is 85% phosphoric acid, pseudo-boehmite, Mg / NaX molecular sieve obtained in step 1, di-n-butylamine and deionized water according to 1: (0-0.7): (0.05-1.2): ( 0.5~1.5): (2~7.0) for mixing in parts by weight, fully stirring at a speed of 500~1000r / min for 3~7 hours to obtain an initial gel;

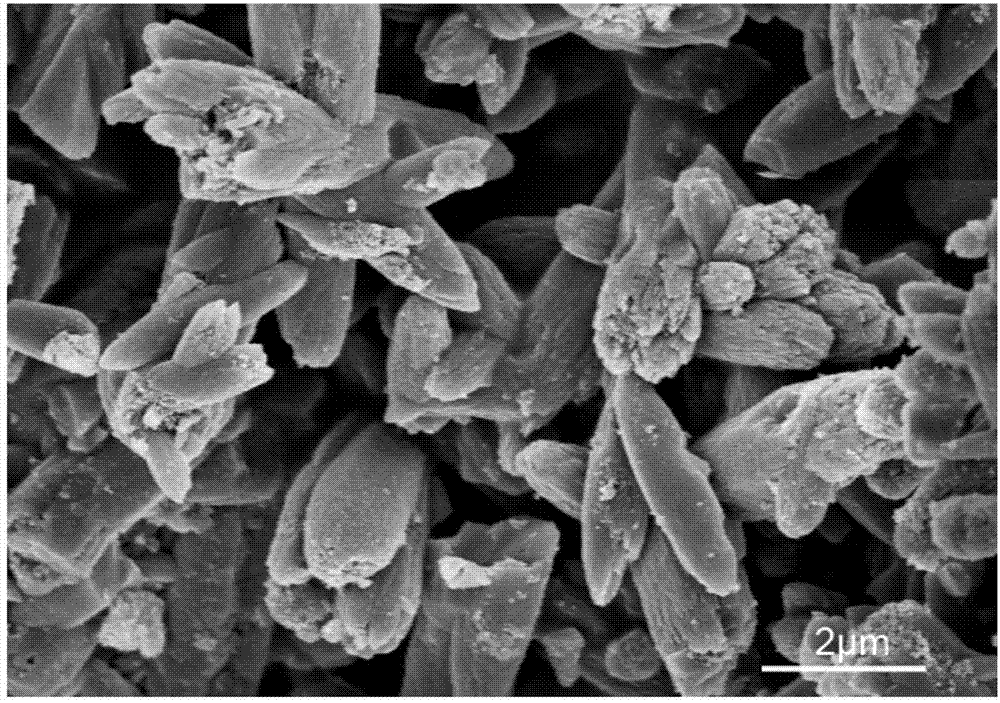

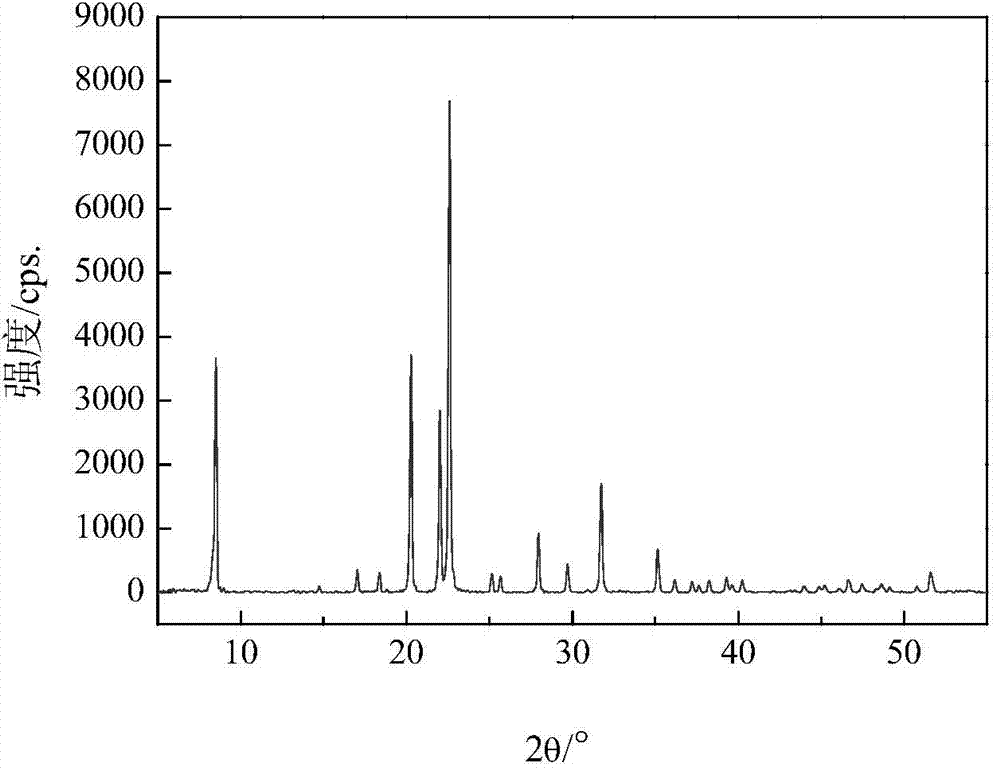

[0025] 3. Place the initial gel obtained in step 2 in a crystallization kettle lined with polytetrafluoroethylene, crystallize at 170-190°C for 12-48 hours, and then cool to room temperature. The crystallized product is centrifuged, washed, and After d...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of the magnesium nitrate solution or magnesium acetate solution described in Step 1 is 0.1-0.4 mol / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the NaX molecular sieve is dispersed in the magnesium nitrate solution or the magnesium acetate solution according to the solid-to-liquid ratio of 1:20-40. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com